12V Two Valve Super-Regen VHF Receiver

This project was the result of needing

an FM receiver that could be run all day, every day, in my workshop, off

the 12V solar supply. Until now I had used the Mains

operated 12AT7 Receiver with the Rohde

& Schwarz vibrator inverter. However, the current consumption of

this arrangement was higher than I'd like, especially when there are several

cloudy days in a row. With the recent development and success of the 6BL8

super-regenerative receiver, I had ideas of developing a new receiver

based on this design, but operating from the 12V house supply.

This project was also going to be the

test for another concept I had been thinking about for quite some time

- how to use 6 volt vibrators and transformers efficiently on a 12V supply.

Broadly speaking, the design would incorporate the new 6BL8 circuit, a

low power one or two valve audio stage, and a synchronous vibrator. Total

current consumption would be around 1A at 12V, this being an insignificant

load on the house batteries.

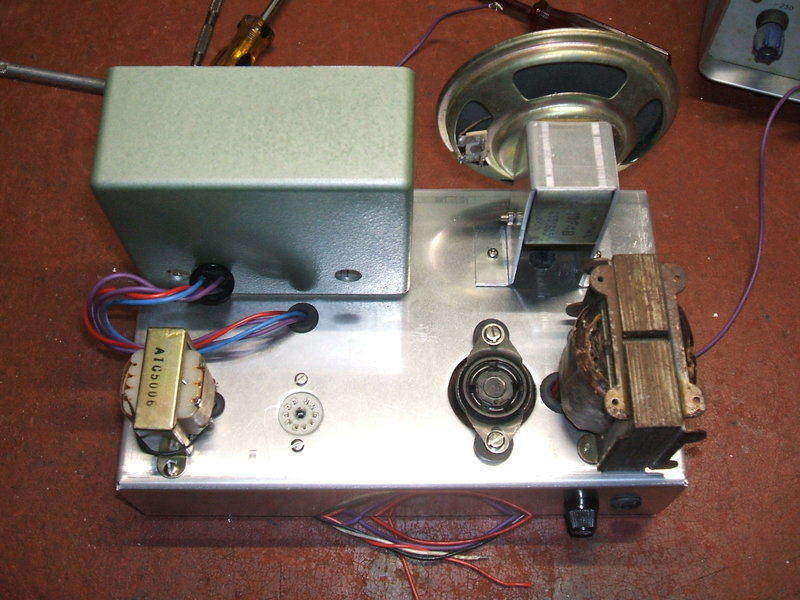

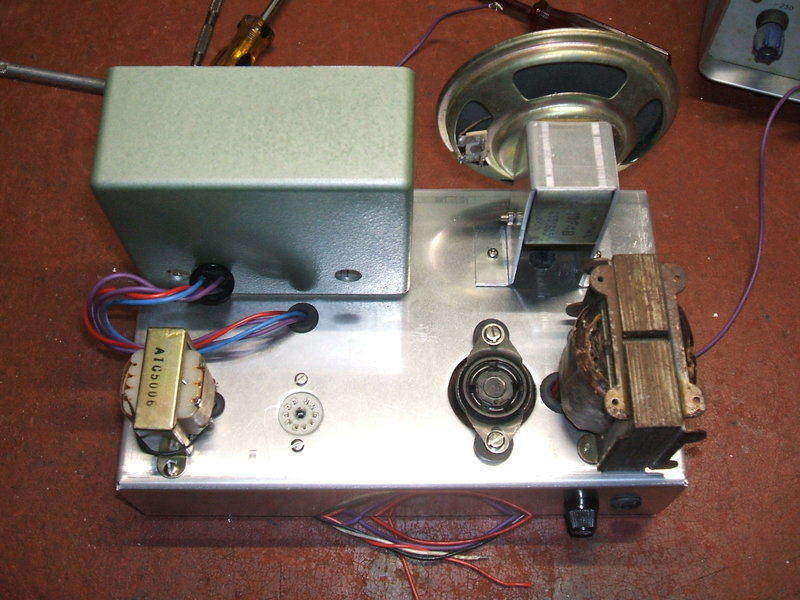

Receiver Module.

From my design work for the Model

T Ford car radio back in 2003, I had left over an alloy diecast box

and chassis which had once contained a 12AT7 receiver used for experiments.

The idea was that the box would be clamped to the steering column of the

Model T with wires run to the amplifier and power supply under the seat.

The final outcome used a different method of construction, but I still

had the receiver box and chassis left over. It seemed ideal to use the

box and chassis for the new receiver, since all the metal work was already

done, and the same layout suited the new 6BL8 design. Using a modular concept

such as this, it meant that the receiver could be optimised independently

of whatever design I chose for the power supply and audio stages. Furthermore,

with all the VHF circuitry contained in a shielded box, the layout of the

rest of the receiver would be non critical.

The 6BL8 circuit was constructed on the

small chassis, and worked exactly like the prototype, with good reception

of 2NUR-FM, a station about 135km away. This has proved that the circuit

could be duplicated successfully. The B+ and heater connections are fed

in via a 4 pin plug and socket, and the audio output is via an RCA socket.

Aerial input is via a BNC socket - this being a legacy of the original

Model T radio experiment.

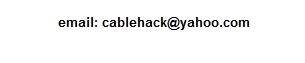

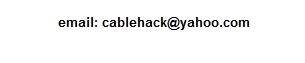

Receiver module being tested prior to fitting into diecast box.

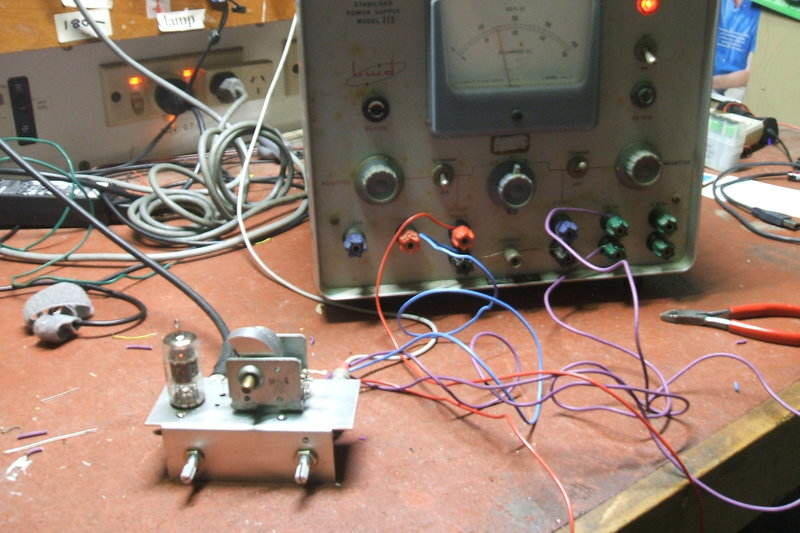

The chassis is attached to the box lid

by means of the two potentiometers. As with some of my other super-regenerative

receivers, an MSP metal tuning capacitor is used, originally intended for

MW superhet receivers. The aerial section is not used, but the lower capacitance

local oscillator section works quite well with a series capacitor to restrict

the tuning range. The drawback to this scheme is that the stations at the

high frequency end of the band tend to be cramped together, while those

at the low end of the band are spread out. Nevertheless, the whole FM band

is covered, along with part of the aircraft band. For those wanting a receiver

specifically for the aircraft band, the circuit merely requires a small

modification of the tuning circuit.

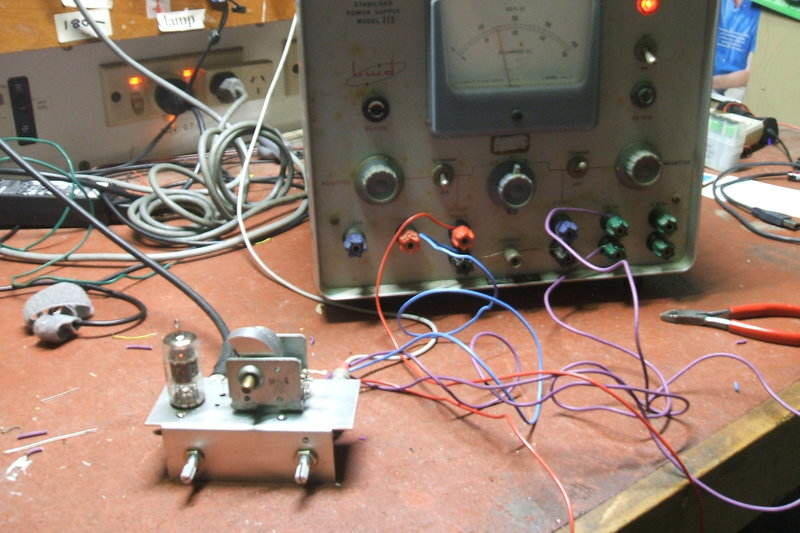

Top of receiver module chassis. At left is the audio output, followed

by the 4 pin power socket, and at right, the aerial socket.

The diecast box was sprayed in green hammertone

paint. This vastly improved its appearance, and once the vernier dial and

knobs were fitted, it had a very professional look about it.

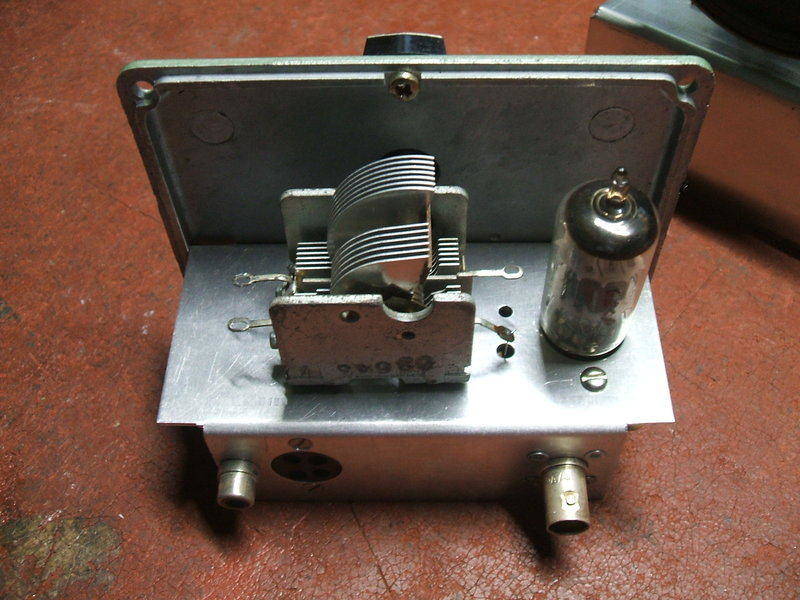

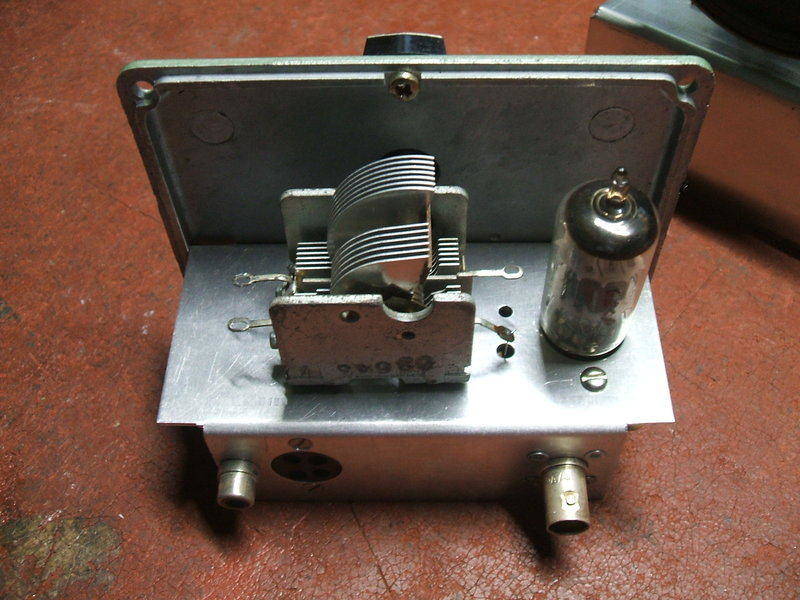

Under chassis shows compact construction.

Main Chassis.

This would support the speaker, vibrator,

transformer, audio amplifier, and of course, the receiver module.

A suitable looking 4" speaker was taken

from my collection, but as is typical with many speakers of small size,

there were no mounting holes. To support it on the chassis, I made a U-shaped

bracket which clamps around the magnet. This worked perfectly. I have some

reservation in mounting a bare speaker like this with no baffling, because

it means bass response is less than it should be. However, a super-regenerative

receiver is not hi-fi, and this receiver would not be operated with particularly

high volume anyway.

Once the speaker type had been determined,

the next thing was to confirm the vibrator transformer I wanted to use

would be suitable. The details of this will be described later.

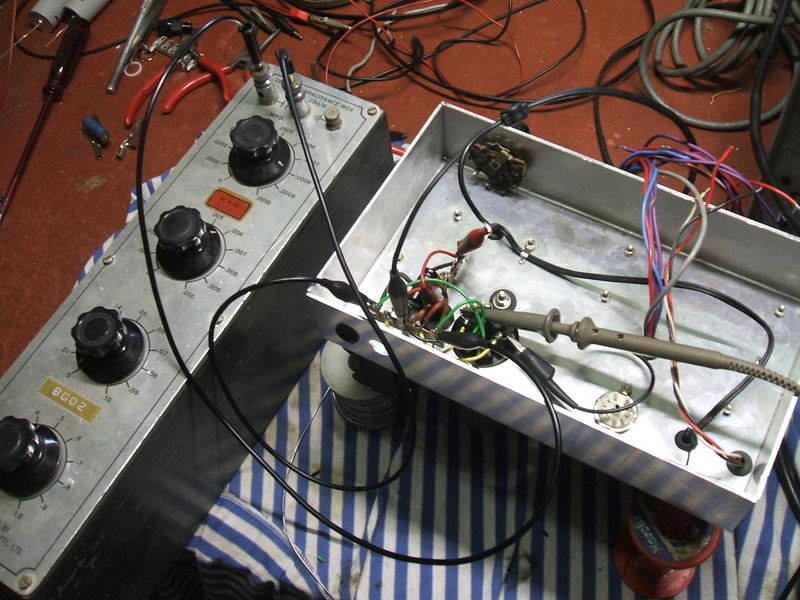

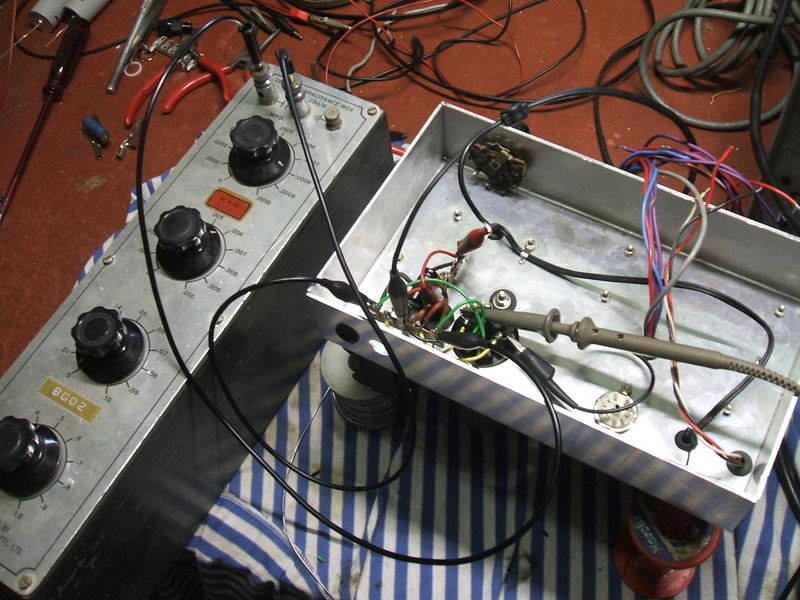

Vibrator transformer being tested.

With the larger parts now known, the chassis

plan was drawn up, and the aluminium cut and bent. The hole for the vibrator

socket was punched out, and the socket itself mounted on rubber grommets

to reduce mechanical noise. The vibrator, a Mallory 245, requires a UY-5

socket. It so happens that the plane of the reed inside the vibrator is

in line with the socket mounting. This method of mounting works well because

the vibrator can swing in the direction of reed travel.

Starting to resemble the final product with the major parts mounted.

Some thought had to be given to the audio

amplifier because of the B+ voltage being around 150V, and as will become

apparent later, the heater current needed be around 700 to 800mA. Various

combinations and types of valves were considered, and ultimately a 6Y9

was chosen. This was tested on a solderless breadboard to confirm suitability

for audio use with this receiver. Once this was done, the speaker transformer

and a 10 pin valve socket were mounted.

Speaker transformer and 6Y9 socket mounted, along with fuse holder

and supply cable grommet.

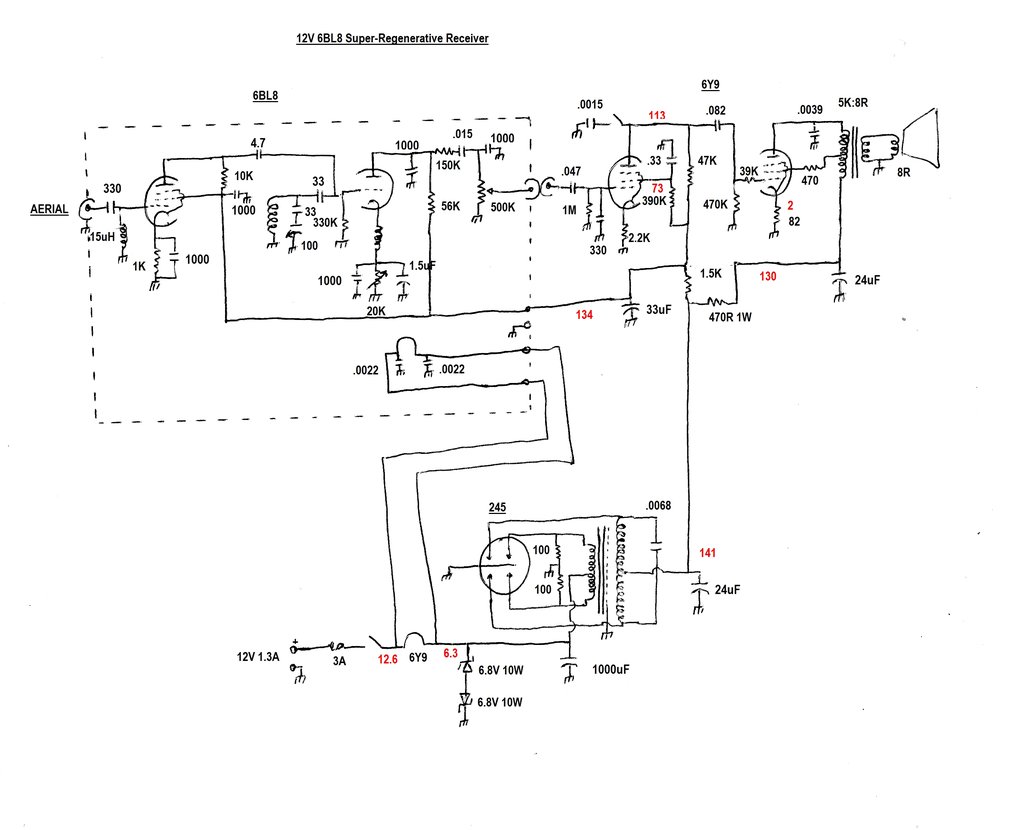

Circuit Design.

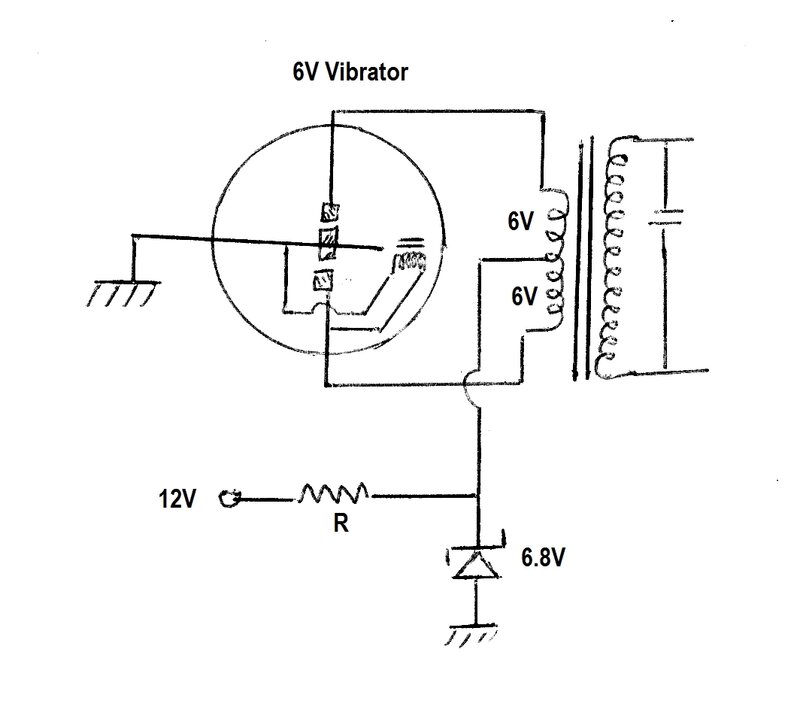

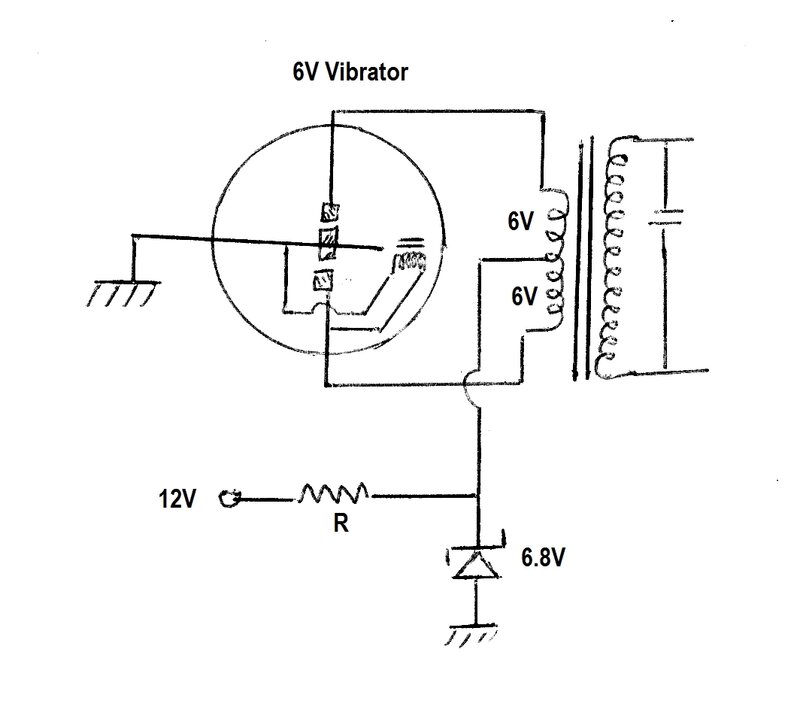

The new design uses a novel method for operating a 6 volt vibrator.

Voltages are marked in red.

1. Receiver.

This has been discussed in detail here.

A 6BL8/ECF80 triode pentode valve is used, with the pentode section performing

as an untuned RF amplifier. This is required to prevent aerial loading

affecting the detector performance. It also provides a small amount of

gain and reduces detector radiation.

The triode section operates as a self

quenched super regenerative detector. The triode is wired as a Colpitts

oscillator, with a quarter wavelength cathode choke and the grid to cathode

capacitance causing oscillation. It oscillates at the received frequency

(88-108Mc/s) by virtue of the tuned circuit. This consists of a four turn

coil and a 100pF tuning capacitor with a series 33pF capacitor. The latter

is used to restrict the tuning range. Ideally, a 15pF variable capacitor

would have been used, but as I have a good supply of N.O.S. 100pF types,

one of these was used instead. The tuning capacitor is actually a type

intended for superhet MW receivers, and in this circuit I am using only

the local oscillator section.

Quenching is obtained by the grid circuit

time constant; i.e. the 330K and 33pF. The long time constant causes the

circuit to go in and out of oscillation at a super-sonic rate. The amount

of oscillation needs to be adjustable for optimum reception, and this is

achieved by the 20K cathode rheostat. It is bypassed for VHF by the 1000pF,

and for audio by the 1.5uF.

At the triode plate, the detected audio

is present, along with the fairly high amplitude quench waveform. This

is filtered to a sufficient degree by the 150K and two 1000pF capacitors.

Because both ends of the 6BL8 heater are

above earth in this receiver, both heater pins are bypassed with .0022uF

ceramic capacitors. This is important because the cathode for the detector

triode is live with RF, and some energy will be capacitively coupled to

the heater.

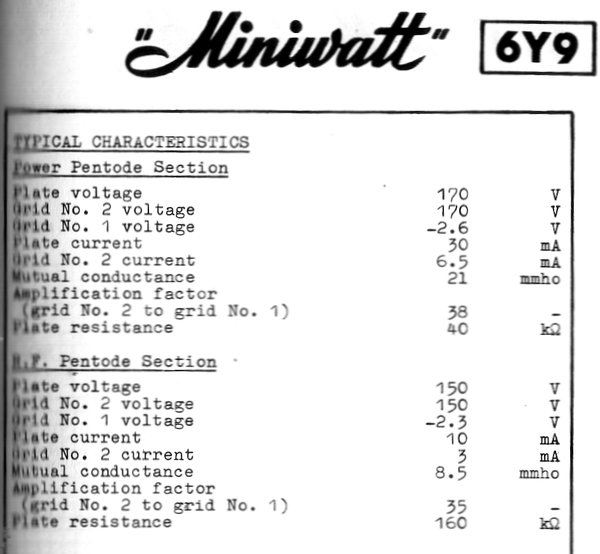

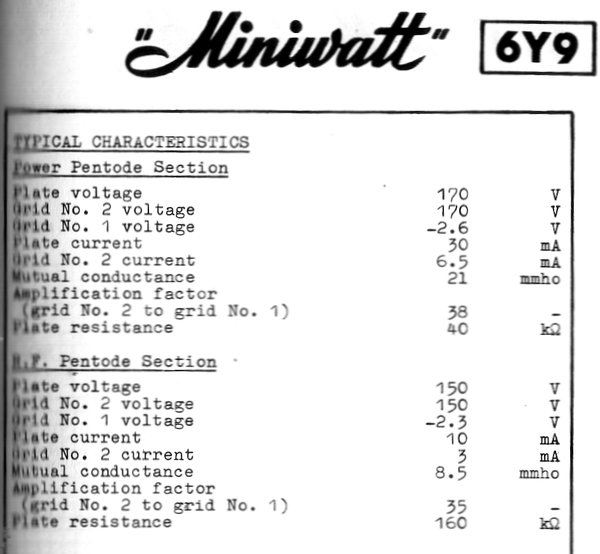

2. Audio Amplifier.

This part of the set is based around a

6Y9/EFL200 dual pentode. The 6Y9 is a frame grid valve introduced in the

1960's for television use. It is unusual in that it has a 10pin base which

looks very similar to the more common B9A type. In Europe, the series heater

type PFL200 is more common, but in Australia, the 6Y9 was very popular

in sets using European valve types. The two pentodes are not the same.

One is a low power signal pentode typically used as a sound IF amplifier,

and the other is a high gain video amplifier.

Video output valves work well as

medium power audio output valves, with the higher gain being useful in

many instances, and in Australia this was commonly done. For instance,

there were several mid 1950's STC radios using the 6CH6 in the audio output.

Most commonly, the 6DX8 was used in TV sets, and a few radios and record

players. Philips in Australia actually gave the 6DX8 official audio ratings

for both single ended and push-pull use.

In one article of the Philips Miniwatt

Digest, some thought was given to using the 6Y9 as an audio valve when

this valve was introduced. However, if they did give it ratings for audio

use, it would have been in a later issue which I do not have. I have seen

the circuit of a Calstan portable radiogram using a 6Y9, so the valve has

been used in at least one commercially made product this way. A particularly

interesting aspect of the 6Y9 is the incredibly high gain, at 21mA per

volt for the power pentode. One could envisage the power pentode being

fully driven from a crystal pickup, which is done with the Calstan circuit,

or a one valve regenerative MW receiver able to drive a speaker at full

volume. However, it must be remembered that these high figures of gain

can actually be problematic for audio use, and careful attention to design

is important.

Part of the Australian Philips data for the 6Y9.

As I have a lot of 6Y9's in my collection,

I thought that this new receiver would be ideal for testing this valve

for audio use. Furthermore, I was looking for a valve which would pass

about 25mA at 150V (the reasons for this will be described in the power

supply section later).

A test circuit was wired up for the power

pentode, and there didn't seem to be any difficulty with getting it to

operate. Because of the high gain, screen and grid stopper resistors are

necessary. A cathode bypass capacitor was not required in view of the high

gain, and eliminating it also provides a convenient method of obtaining

negative feedback.

With a B+ of 136V, maximum output was 285mW,

and input sensitivity was 1.2V. If a cathode bypass was included, sensitivity

was 540mV. B+ current was 26mA. The ideal load impedance is therefore about

5.2K, which suits a 5K P.A. line transformer as I have used with other

projects.

The super-regenerative detector can't quite

drive the 6Y9 power pentode to full output, so the signal (RF) pentode

is also required. Like the power pentode, this too has a very high gain.

In view of this, gain was kept low by means of a low value plate resistor

(47K as opposed to the usual 100K to 220K), and again by not bypassing

the cathode. Without cathode bypassing, the stage gain is 12, and with

the capacitor it increases to 52.

It could be imagined that with both pentodes

of such high gain, using them together as an audio amplifier is likely

to produce instability, and not surprisingly this did occur. A 330pF capacitor

at the signal pentode grid cured the problem, along with a 3900pF bypass

at the power pentode plate.

A super-regenerative receiver is quite

noisy on a weak signal, and as this receiver was intended to listen to

a station which is often weak, it was thought a good idea to include a

treble cut option. By reducing the high frequency response, the noise is

reduced and the receiver is more pleasant to listen to. In this set, a

.0015uF capacitor can be switched in between the 6Y9 signal pentode plate

and earth.

Finally, as noted elsewhere on this site,

some P.A. line transformers can be problematic as valve output transformers.

The resultant audio often sounds very shrill and unpleasant to listen to.

This can be improved by operating the output in ultra-linear or triode

mode. This was the case with the new receiver, and the 6Y9 screen was fed

from the 2.5K tapping on the transformer primary. Further details of the

problem are described here,

and in fact the same type of transformer was used.

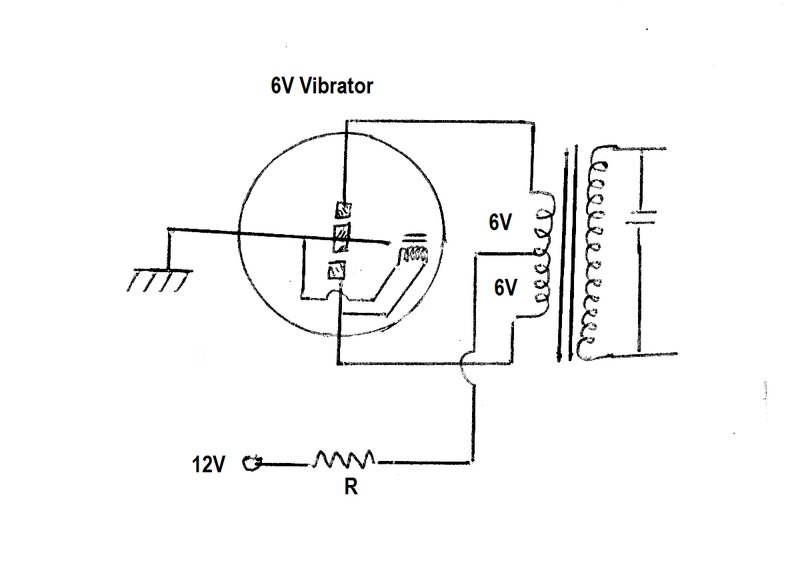

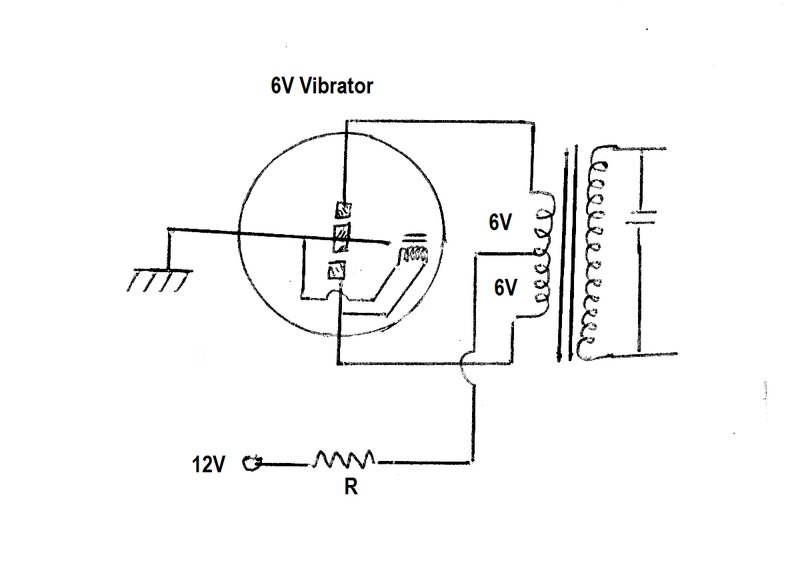

3. Power Supply.

This set was going to use a vibrator to

enable operation off the 12V house supply. While there are several vibrator

powered sets described elsewhere on this site, this set takes a very unusual

approach and most of this section will be spent describing it.

I have a lot of 6V vibrators in my collection

and it seems a shame not to use them in new projects. The problem of course

is that 12V supplies are much more common than 6V in the modern day. The

series drive types can easily be used on 12V with a resistor in series

with the drive coil.

But, a large proportion I have are shunt

drive types and I wanted to use one of these. However, except for a very

few types, it is not possible to isolate the drive coil to include an external

dropping resistor. Thus, the vibrator can only work on 6V.

Furthermore, I wanted to use a synchronous

vibrator with synchronous rectifier circuit. This of course requires a

proper vibrator transformer with centre tapped secondary. And, as it happens,

most examples I have of this type are also 6V.

So, how can one use a 6V vibrator and transformer

on a 12V supply? One method which allows efficient use of a 6V transformer

is described here, but

is only suitable when the vibrator is 12V, or is a series drive 6V type

with coil resistor in series. The vibrator must be a split-reed type, and

a valve or solid state rectifier must be used.

At first thought, a dropping resistor would

be a simple way to use a 6V vibrator and transformer from a 12V supply.

However, there is a problem in that until the valves warm up, the load

on the vibrator is much less than normal, and because the resistor is chosen

for dropping 6V at normal operating current, the vibrator and transformer

will be exposed to higher than normal voltage. Apart from not being good

for the vibrator drive coil, the transformer may suffer damaged insulation,

along with the timing capacitor being overly stressed. In the case of circuits

using a synchronous or solid state rectifier, the filter and other capacitors

may also be exposed to excessive voltage. Also, it needs to be remembered

that unless there is a large amount of capacitance connected to the transformer

centre tap, the supply actually rises back up to 12V in between the time

when the contacts make. Keeping in mind the drive coil is in circuit during

this time, it can be seen that it will be exposed to excess voltage.

This is NOT acceptable because the vibrator, transformer, and other

components, are exposed to excessive voltage when the supply is not fully

loaded.

If, however, the supply is always loaded,

the idea becomes viable. In this

power supply, this technique was used successfully. The B+ output of

the power supply is clamped by zener diodes, and thus the vibrator

input current is always the same, regardless of if the valves are drawing

current or not. There is a large electrolytic capacitor connected across

the 6V supply so the driving coil is not exposed to excess voltage.

Alternatively, the 6V supply can be clamped

by a zener diode instead. During warm up, the zener conducts, clamping

the input to the vibrator to a safe level, and once the valves have warmed

up, the zener ceases to conduct.

The drawback of course with a dropping

resistor is efficiency loss, because half the input power is wasted across

the resistor, but in this case the output power required was very low to

start with, and the power wastage was acceptable. In practice, the zener

diode of course needs to be a high power type.

Zener diode prevents the 6V supply rising during periods of no load,

such as valve warm up. Drive coil is also protected when reed is between

contacts.

A further extension of this concept is

quite ingenious and can result in efficiency as good as if a 12V vibrator

and transformer were used to start with. Until now, we have considered

only the vibrator and its transformer, but in most instances the vibrator

will be powering something with valves; e.g. a radio receiver. Most indirectly

heated valves, such as the ones used in this receiver, are designed for

6.3V operation. So, what if the heater circuit happened to have the same

current consumption as that of the vibrator? It can immediately be seen

that the valve heaters could take place of the dropping resistor. Effectively,

the vibrator would act as the dropping resistor for the valve heaters,

and conversely, the valve heaters would act as the dropping resistor for

the vibrator. The result is that both the valve heaters and vibrator get

their required 6 volts without any other resistors and full efficiency

is obtained.

The choice of zener voltage requires some

thought. It should not merely be 6V (6.2V is the closest preferred value).

This is because a 12V battery supply can vary from about 11V to around

15V depending on charge, and if the battery is being charged when the receiver

is in use. If the supply was 14V as when the battery is being charged,

and a 6V zener was used, then 8V would appear across the valve heaters.

Also, the zener would be conducting, getting warm, and wasting power. By

having a zener of 7.5V, the voltages between vibrator and heater would

divide equally up to a supply input of 15V. Thus, if the supply was 14V,

the heaters would receive 7V which is much more acceptable, and no power

would be lost in the zener diode. The warm up voltage of the vibrator would

be a maximum of 7.5V, but this is within ratings as vibrators are designed

to work over normal battery voltages. Essentially, the zener diode operates

only during warm up. It should be obvious that when conducting, the zener

diode current will be the normal full load current (at 6V) of the vibrator

supply minus its no load current. If the vibrator is removed, the zener

has to carry the full heater current.

Under certain fault conditions that cause

the vibrator to draw excess current, such as a short circuit on the B+

supply, the valve heaters would receive excess voltage. However, with modern

capacitors used the chances of this are so remote as not to be worth worrying

about. Several methods could be used to protect the heaters if this was

of concern.

In practice, to design this setup to work

efficiently requires a bit of a juggling act so that the vibrator current

works out the same as the heater current. This means the total B+ current

has to be taken into consideration, as well as the valve types and their

heater currents.

Of course, a balancing resistor can take

care of any discrepancy between the two currents. For example, if the vibrator

draws more current than the heaters, a shunt resistor can be connected

across the heater circuit, and vice versa.

A disadvantage of connecting a zener diode

across the vibrator input is that the supply must be polarised. If the

supply is reversed, the zener conducts like a normal diode with a drop

of about 0.7 to 1V. In this case, the 6.3V heater string would receive

virtually the full 12V.

The zener diode has to be made bi-directional

therefore, so it clamps with both polarities. This can be done by including

a bridge rectifier before the zener, or more simply with two zeners of

the same voltage back to back.

In the case of the bridge rectifier arrangement,

1.4V needs to be added to the zener voltage to obtain the clamp voltage.

With back to back zeners, only 700mV is added.

It is true that for synchronous vibrator

circuits, the input is already polarity conscious, but accidents do happen,

and polarity may be reversed until it's realised the radio is not working

after the warm up time. While the B+ electrolytics will be exposed to reverse

voltage in this situation, they will stand it for the short period of time.

The vibrator may be overloaded since the B+ current will be somewhat higher,

but no lasting damage should be done if the set is switched off quickly.

Simply connecting a diode in series with

the 12V supply to protect against reverse polarity wastes voltage, which

is important particularly as the batteries approach discharge. A diode

shunt connected so it blows the supply fuse is commonly used with 12V circuits,

but it is inconvenient as one must have a supply of fuses to hand, "just

in case". Alternatively, a relay can be used; the normally open contacts

in series with the supply, and the coil fed via a diode. Thus, the relay

only connects the supply if the polarity is correct. A simpler and better

scheme is to connect a diode in series with the first filter electrolytic

on the B+ side. Here, the small voltage drop is trivial. Of course, where

a non synchronous vibrator is used, input polarity is not important, provided

any capacitors on the 12V side are non polarised.

Now to the design of the power supply used

in the new receiver. The transformer chosen was a type made by Radio Corporation

and used in Astor receivers amongst others. It was tested and found to

provide about 150V. Clearly, it was intended for operating battery type

valves, and would have been used in a domestic vibrator set. Typical current

rating for such a transformer is about 20 to 40mA. Another transformer

I had was of different manufacture, and with a larger core and 250V output

would have been intended for car radio use. I chose the 150V transformer

in view of wanting to keep the input current around 1A, which it would

be with around 20mA current draw at 150V.

The next question was what vibrator to

use. This time I wanted to draw on my supply of U.S. made types. Most of

my synchronous types happened to be made by Mallory and I decided on type

245. This fits a UX-5 base which is one reason I chose it; I have a good

stock of these. Being of Mallory quality, it didn't take long to get the

vibrator started and the contacts clean after many years of not being used.

Timing Capacitance.

One of the most important aspects of vibrator

circuit design is of course the timing, or buffer, capacitor. The value

is important, and if not chosen correctly, vibrator life will be short.

Much discussion has already been provided in articles elsewhere on the

site with regards to this.

For the Radio Corporation transformer,

a look through all the circuits in the Australian Official Radio Service

Manual showed that all sets using it had a .004uF timing capacitor across

the whole secondary, and a .05uF across the primary. The latter value has

only a very small effect on overall timing capacitance and exists primarily

for interference suppression. The vibrators used with this transformer

were all Ferrocart synchronous types. Looking through types that would

have been used, all were 100 or 115 cycle. Therefore, the nominated timing

capacitance should suit the Mallory types operating at 115 cycles. Some

time was spent determining a suitable value, as it seemed that .004uF had

been chosen as an "ideal" value which does not allow for vibrator aging.

Selecting the vibrator timing capacitor with a decade capacitance

box.

Mallory advises that the slope of the waveform

should be 65%. In other words, the amount of timing capacitance is made

slightly more than the ideal. This is because as a vibrator ages, the contact

spacing may increase slightly. If this happens, and the circuit has been

set up with the ideal value of capacitance, there will now be insufficient

capacitance, with all the problems that entails. It is more acceptable

to increase the value of timing capacitance than decrease it, since contact

damage as well as transformer insulation failure can occur with insufficient

capacitance. Increased capacitance is not ideal from a timing point of

view, but the transformer will be protected, and contact wear will be minimal

provided the capacitance is not excessive.

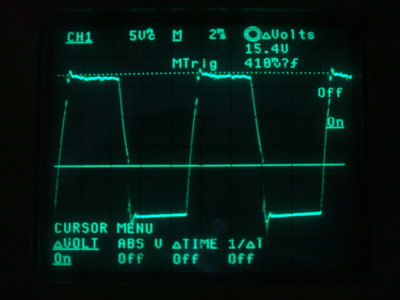

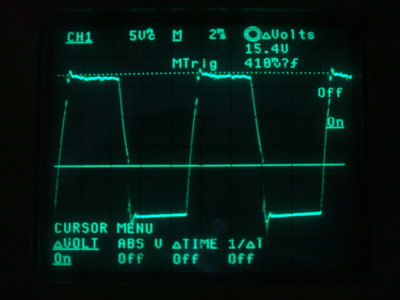

Left waveform shows .004uF; at right is with .0068uF.

Experiments found that for a 65% slope,

the capacitance should be .0068uF. As can be seen in the right hand side

waveform, the slope is measured at 15.4V from the top of the waveform,

which is 23.4V. A simple equation of 15.4 / 23.4 gives 66%.

A 2000V polypropylene type was used.

It is good practice to include primary

damping resistors, so 100R 1W types were connected across the primary contacts.

6 Volt Vibrator Supply.

Once the audio section had been constructed,

it was found that the input current to the vibrator was 1.25A at 6.3V.

Conveniently, this happened to be exactly the same as the heater current;

450mA (6BL8) and 800mA (6Y9). Thus, no balancing resistor was required.

Two 6.8V 10W zener diodes were connected

back to back across the 6V vibrator supply. During warm up, the voltage

rises to about 7.5V. This is within limits of the vibrator circuit. As

the zener diodes dissipate power for only a short time, minimal heatsinking

is required. A strip of aluminium on which the diodes are attached to each

other is adequate.

12 Volt Input.

A two pin polarised plug connects the

receiver to the house supply. A fuse is included to protect the wiring,

particularly in case of switch break down. The gauge of wire connecting

the set would burn up before the house breaker tripped otherwise.

The power switch is a two pole three position

rotary switch of Oak (MSP) manufacture. As well as turning the receiver

on or off, the third position also switches in the treble cut capacitor.

The Completed Receiver.

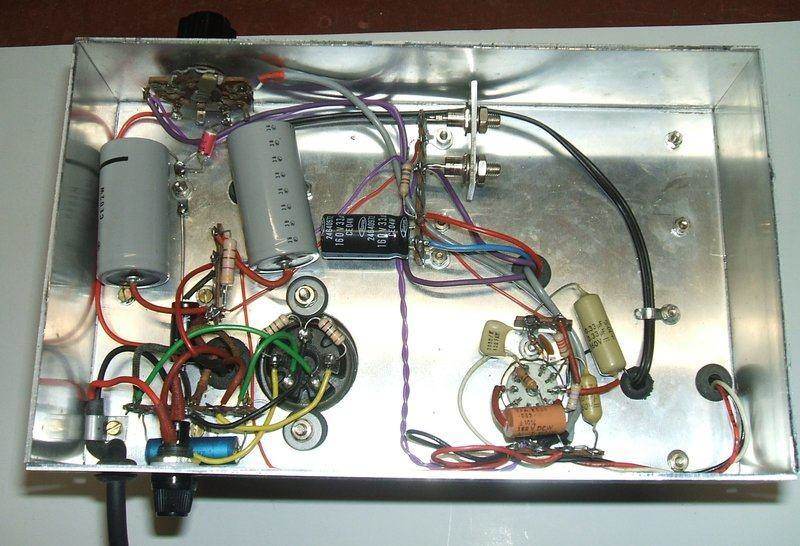

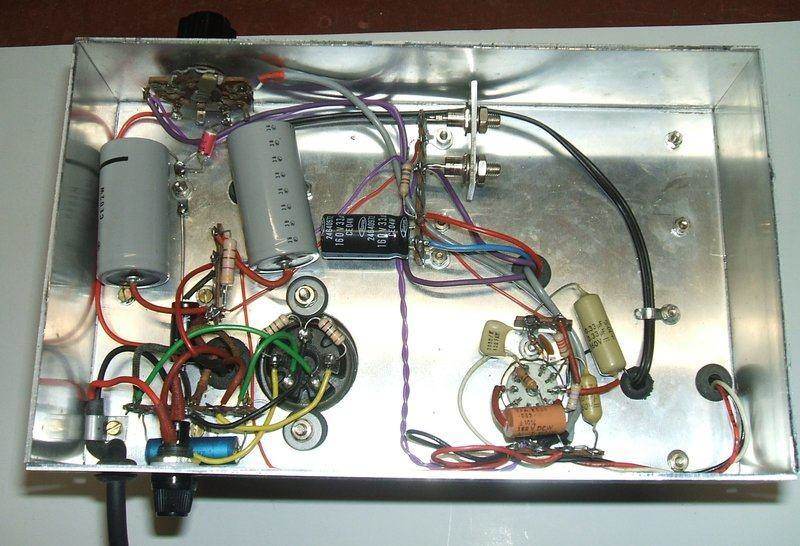

Under chassis wiring completed. The two 10W zener diodes are visible

at the top towards the middle.

Once the wiring was completed and the receiver

was operating correctly, the front and rear panels were labelled. While

it is true that only I would operate the receiver and therefore know what

the controls are, it does add something of a professional appearance to

label everything.

Front panel labelling.

Rear panel labelling.

Performance.

In terms of sensitivity, the receiver

works just the same as the other valve super-regenerative receivers described

on this site. Sound is slightly lacking in bass because of the speaker

not being baffled. The tone control works effectively, and makes weak signal

listening easier.

The low current consumption is very

pleasing, and the new technique of using 6V shunt drive vibrators with

a 12V supply works perfectly. This method will be used in future projects.

Update 4/08/25.

With the acquisition of quantity of VHF

ceramic variable condensers, the existing MW type was replaced. It suffered

from intermittent contact on the wiping connections, which were just not

good enough for VHF.

New tuning condenser allows reliable tuning across the band with

no dropouts.

The tuning condensers are about 5 to 29pF.

This is a much more suitable value for tuning across the FM broadcast band,

and eliminates the series 33pF padding capacitor.

Tuning range is now 77 to 139MHz. It thus

covers the full aircraft band, as well as the FM broadcast band.

Another improvement was to reduce the

grid resistor from 330k to 270k, to increase the quench frequency. It was

found that intermodulation distorion could be a problem with the regeneration

control set at the most sensitive position. The quench frequency is set

by the grid resistor and capacitor time constant, but also varies with

the regeneration setting.

These two improvements have made this

receiver much more pleasant to use. Sound quality is better, and there

are no more dropouts when tuning across the band.

Improvements (10/12/25).

Using a 6JW8.

In many of the VHF super-regenerative

receivers described on this site, the local oscillator section of an AWA

(MSP) tuning condenser has been used. This is about 90 to 100pF, and as

such, a padding capacitor of about 33pF is connected in series for correct

coverage of the FM band. With some of these receivers, a problem has existed

in that the capacitor appears to develop intermittent connections as it

is rotated. A pattern has now emerged, that in all instances the receivers

have used low mu triodes. My attention was drawn to this when replacing

the tuning capacitor in this receiver with a proper ceramic VHF type did

not completely eliminate the problem. Realising this, I first tried a 6U8,

since this has twice the mu of a 6BL8, but it did not fix the problem.

The triode of a 6JW8 is much closer to

a 12AT7, and it did fix the problem. This valve was chosen because

it has the same pin connections as the 6BL8. The following table shows

the characteristics for triodes used in the super-regen receivers described

on this site. The E88CC is not included, since that

receiver operates under different conditions.

| Triode |

Transconductance |

mu |

| 6BL8 |

5 mA/V |

20 |

| 6DX8 |

4 mA/V |

65 |

| 6ES8 |

12.5 mA/V |

34 |

| 6GK5 |

15 mA/V |

78 |

| 6JW8 |

3.5 mA/V |

70 |

| 6U8 |

8.5 mA/V |

40 |

| 12AT7 |

5 mA/V |

60 |

| 7193 |

3 mA/V |

20 |

A puzzling characteristic is the mu of

the 6ES8 is only 34 despite the high transconductance. Only one

source of data I've found actually shows this - most data books do

not show the mu for the 6ES8. If this is correct, it seems therefore, the

best triodes to use have an extremely high transconductance and/or a high

mu.

The conclusion is that if you have a 6JW8,

use it in preference to the 6BL8 or 6U8. It appears that the higher gain

triodes oscillate in a much more lively manner, which overcomes the poor

capacitor contacts.

Other improvements:

-

Motorboating at full volume was fixed by changing

the 24uF B+ filter for the 6Y9 to 100uF.

-

6Y9 gain was increased by bypassing the output

section cathode with a 22uF capacitor.

-

It was noticed the B+ was down to around 90V,

and that the vibrator was not drawing its normal current (the zener diodes

were warm). After nearly seven years of regular use, the contact spacing

has widened to the point of the existing timing condenser not being of

sufficient capacitance. An extra capacitor of 0.01uF was added in parallel

(0.0168uF total). B+ returned to about 137V.

-

A 47R 5W resistor was added across the 6.3V

input to the vibrator for better current equalisation.

-

The four pin socket had poor connections resulting

in annoying intermittent faults. The contacts were tightened.

Home