Knowing of my interest in vibrator powered

radios, an acquaintance in the HRSA provided me with this set. What is

particularly unusual is that it is for 12V operation. I know nothing of

the set's history, except that my friend had found it at a market.

To give a clearer background to this type

of set, it is first necessary to talk about lighting plants, and the radios

that worked from them. To set the scene, let's go back to 1948 when this

set was produced.

The most common type of domestic radio

in Australia, was of course designed to operate from the AC power mains.

Some country towns, and central business districts of capital cities, instead

had DC mains. In both cases the voltage was typically 210-250V. For further

details about mains supplies, see

this article.

Away from cities and towns there was usually

no mains supply. Small villages and isolated properties away from the reticulation

system were on their own as far as electricity supply was concerned. In

these locations, battery sets were common. These came in a few different

types; the all dry battery set using 1.4V heater valves, with a 90V high

tension. Older sets would use a 2V lead acid accumulator with 2V heater

valves, but still a dry battery HT supply. The all dry battery set was

popular where no facilities existed to charge batteries.

By the late 30's, another type of set

became popular. It used a single 6V accumulator, of the type used in a

car, which provided heater current for the 1.4V or 2V heater valves, and

high tension by a vibrator power supply. It eliminated the need for the

expensive (and non-rechargeable) high tension battery. However, using such

a set did require access to charging facilities. This might be a trip to

the garage in the nearest town every couple of months, or the battery could

be alternated with that in the car (if you had one!).

[Before anyone points out such things

as air cells and rechargeable HT batteries - yes they did exist, but were

not common]

Home Lighting Plants.

Those without reticulated power mains,

and who could afford it, had their own DC supply provided by a "home lighting

plant". This was typically a single cylinder engine driving a generator,

which powered the house electrical system. If batteries were included,

the generator would only have to be run when the batteries required charging.

Otherwise, every time an appliance or light was used, the generator had

to be started. In fact, some systems did allow for remote or automatic

starting.

Other systems used a wind generator. For

these, batteries are obviously essential.

Description of a wind powered 6V lighting plant from 1937.

Home lighting plants appear to have had their origins in the U.S. with a Delco designed 32V system in the 1920's. By and large, 32V systems were the most popular in Australia, but smaller ones operated at 6 or 12V. Larger systems operated at 50 or 110V. Many domestic appliances were available in these voltages; particularly 32V. The 6 and 12V systems were only practical for lighting, radio, and other low power appliances such as a fan. For 32V and above, heating appliances such as irons and toasters become practical.

From this, we can see there was a market

for radios operating from home lighting plants. The 6V systems suited the

charging of batteries for existing 6V vibrator sets. While one might think

of simply using a 6V car radio, this draws about five times the current

of a domestic vibrator set.

The result was sets made for 12, 32, 50,

and 110V DC. For 6 and 12V sets, a vibrator or genemotor must be used to

obtain B+. In the case of 32V sets, this voltage is sufficient to use directly

as B+, where high power output is not required. However, many 32V sets

did use a vibrator. The only circuit diagrams I've found for 50V sets show

the use of 50V as the B+ without a vibrator. 110V sets obviously follow

U.S. design, using the 110V as B+.

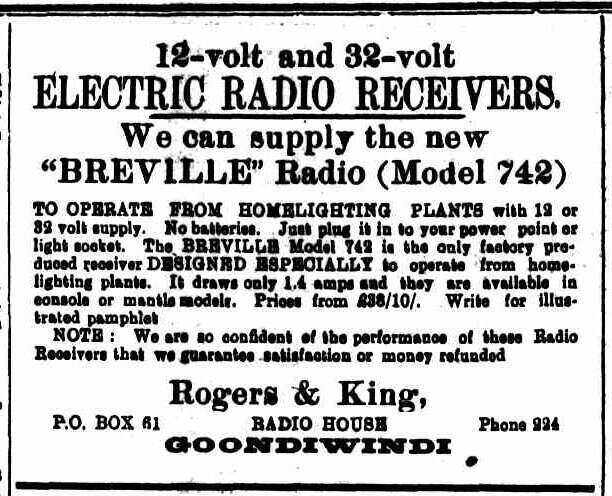

The Breville 12V Home Lighting Plant.

The Breville 742 is the first 12V domestic

radio I have seen. I am not aware of any other manufacturer making sets

for 12V lighting plants. It appears that Breville was supplying 12V lighting

plants, and then designed a radio to suit.

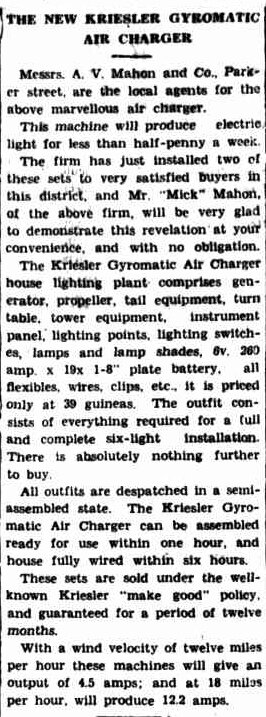

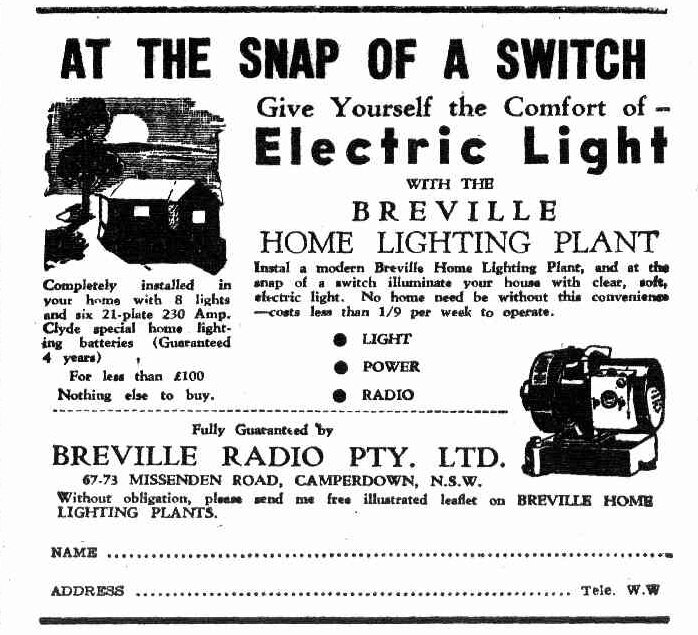

1949 advertisements for Breville's 12V lighting plant.

The 12V Breville home lighting plant had

an output of 300W. This allowed for eight 25W lamps. The battery supplied

was 230Ah, consisting of six two volt cells. The lamps were standard domestic

sized B22 based types, but with 12V filaments.

Readers of this site will know that I

have a 12V home lighting

plant for my own house; the difference being that it is solar powered.

Battery capacity is 300Ah. It can be seen why the 742 was such a desirable

addition to my collection.

I was advised by a very helpful reader

that the Breville generator was actually a rebadge of the U.S. made Johnson

"Iron Horse" which first appeared in 1936. A Canadian version, made by

the Outboard Marine & Manufacturing Co. was called the "Chore Horse".

There is some discussion about it on this

forum.

There is also a very detailed article

by Ray Robinson on his Tube Radio website about the Chore Horse https://www.tuberadio.com/robinson/museum/Chore_Horse/

These generators were used in WW2, and

it would appear that Breville bought them as a war surplus, subsequently

making a radio to work with them. The post war disposals advertisements

in Radio & Hobbies mention a 300W 12V generator, and more than likely

this was the same unit.

The Breville 742.

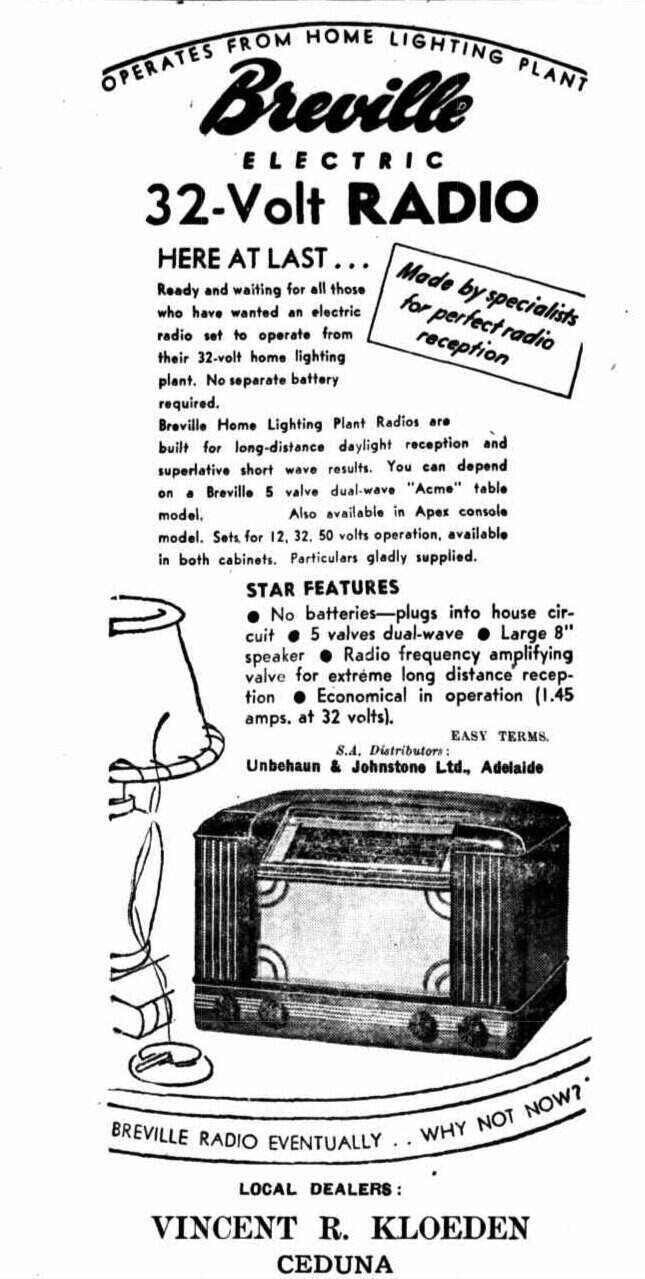

The 742 is a five valve dual wave superhet,

which was available in two forms, a console 742-C "Apex", and the 742-T

"Acme" mantel set. It was available in 12, 32, and supposedly 50V. The

set which came into my possession was the 742-T "Acme".

The set is housed in a large wooden mantel

cabinet with an 8" speaker.

Model 742 Acme.

The appearance of the set was familiar,

since I had restored a 730 back in the late 1990's, which is the AC mains

version, and uses the same cabinet. However, the 730 does not have an RF

amplifier. There is also a 743, which is the AC/DC mains version of the

730.

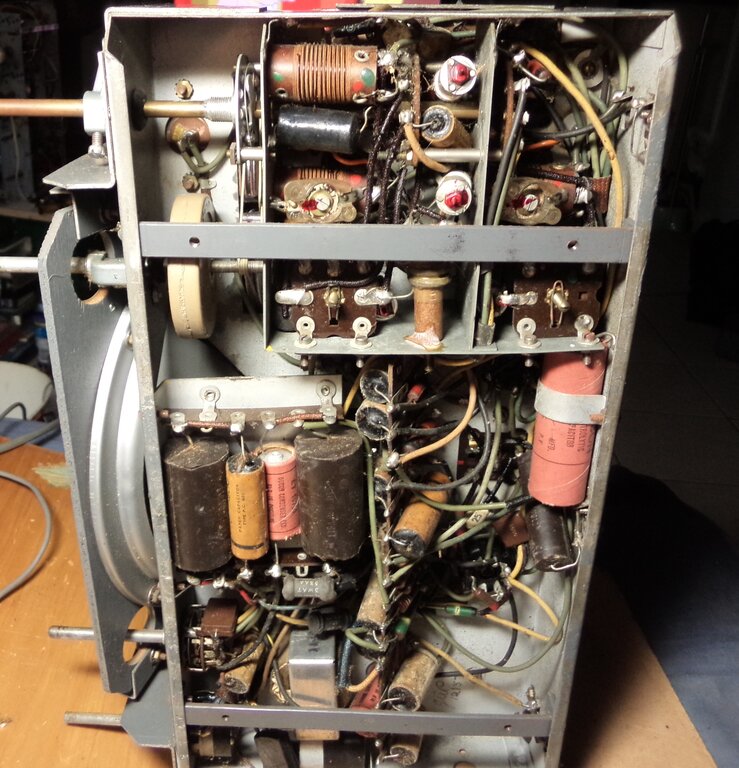

As received, the set had been a little bit 'got at', with the chassis to cabinet screws missing, along with the screws securing the vibrator power supply to the chassis. The dial lamps were missing, and a momentary push button switch had been installed in the side of the cabinet, to allow the dial lamps to operate only when required, thus saving on battery drain. However, this does not appear on the circuit, and the installation does not look original. In practice, an extra 250mA or thereabouts will have minimum effect on a 230Ah battery.

Switch added for dial lamps.

In original condition.

The Circuit.

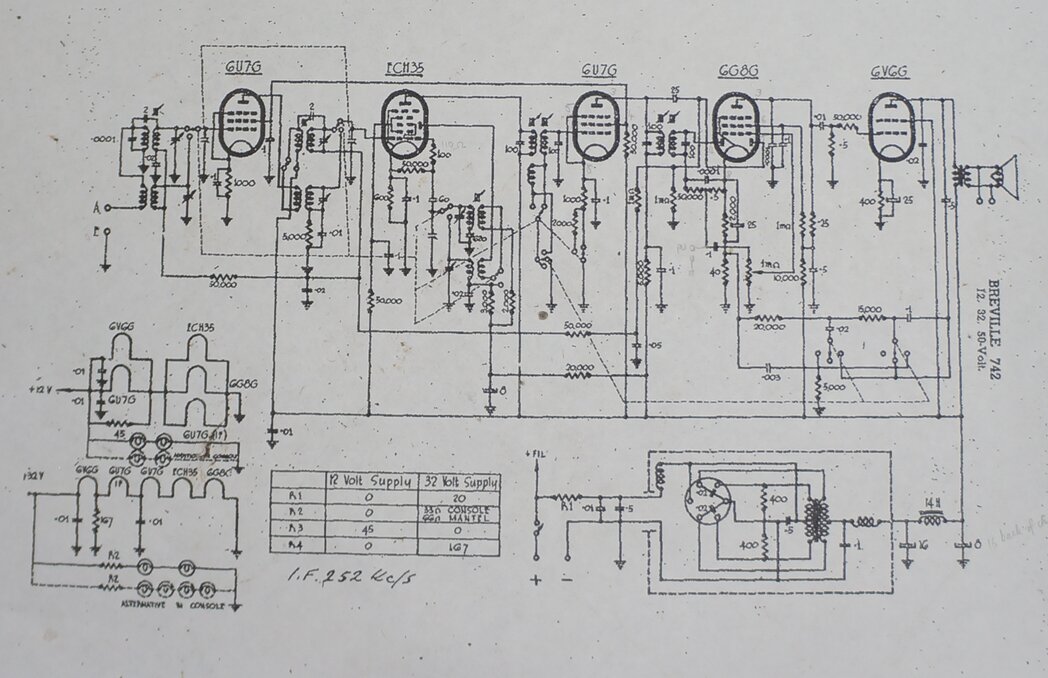

Despite "50-Volt" in the title, there is no such circuit.

For the most part, the circuit is conventional.

Incoming signal is amplified by the TRF stage using a 6U7. This is converted

to the IF of 262Kc/s by an ECH35. IF amplification is by another 6U7, and

detection and first audio is a 6G8. Audio output is a 6V6.

Note that in the SW position, the IF gain

is increased by shorting out the 2K cathode resistor of the 6U7 IF amplifier,

so that the cathode resistance is only 1K. For MW, the total cathode resistance

is 3K.

An interesting thing is the 25pF coupling

capacitor from the IF amp plate to the AVC rectifier. In most sets this

is 100pF. As a result, the AVC voltage produced is not as high, especially

with the higher reactance of 25pF at 252Kc/s.

252Kc/s IF.

The 252Kc/s IF may appear unusual, but

it was used in some car radios, and at least one other Breville set, the

portable 857. The lower IF provides a higher gain and better selectivity.

However, a preselector or TRF stage is required to improve the image rejection.

Because the difference between the local

oscillator and RF input frequencies is a lot less at 252Kc/s than at 455Kc/s,

it is more difficult to filter out the image response with just one tuned

circuit in the aerial input.

Consider a station on 900Kc/s. For an

IF of 252Kc/s, the local oscillator operates at 1152Kc/s. Now, in addition

to the input responding to 900Kc/s, it will also respond to 1152 + 252

= 1404Kc/s. With a single aerial coil, loaded down by a long aerial,

the selectivity will be insufficient to prevent signal from a strong station

around 1404Kc/s entering the input of the converter valve, and interfering

with reception of the desired station at 900Kc/s. Anyone who has used a

crystal set in a strong signal area with multiple stations, will be familiar

with the limitations of a single tuned circuit.

If the IF is increased to 455Kc/s, the

local oscillator is now 1355Kc/s. The image response will therefore be

1355 + 455 = 1810Kc/s. Not only are there no broadcast stations at this

frequency, but 1810Kc/s is much further away from 900Kc/s than 1424Kc/s.

A single tuned circuit now has a better chance of rejecting the image frequency.

Tone Control.

As with all good quality radios using

a pentode or beam tetrode output valve, negative feedback is included.

In the 742, the frequency response of the feedback network is adjustable

by means of a three position rotary switch, which functions as a tone control.

The feedback network is fed from the 6V6 plate via a 0.5uF condenser.

In the mid position, the negative feedback

is not frequency selective, giving a flat response. Voltage from the 6V6

plate is fed via the 0.5uF, and 15K and 20K resistors into the 40R to earth.

The voltage divider (35K + 40R) introduces the feedback into the 6G8 cathode.

In the high position, the junction of

the 20K and 15K is partially shunted to earth by a 0.02uF in series with

a 5K. As the frequency rises, the reactance of the 0.02uF decreases, shunting

more of the signal to earth. Thus, the 6G8 receives less negative feedback

at high frequencies, and more feedback at low frequencies. With the gain

of the audio system reduced at low frequencies, the result is more treble

response.

In the low position, a 0.003uF is connected

across the 20K + 15K. As frequency rises, the feedback increases, and gain

rolls off. The result is more bass response.

Additional to the tone control is an extra

winding on the first IF transformer. The tone control also controls the

selectivity of this transformer. Without opening and examining the transformer,

it appears the coupling is altered, giving a narrower or broader response.

This is also tied in with the MW/SW switching.

Presumably, the response is wider when MW is selected to give good fidelity.

For SW, where selectivity and gain is more important, the response would

be narrower.

Pick Up Terminals.

Pick up terminals are provided, but are

not shown on the circuit. Connection is between earth and the junction

of the 0.1uF, 50K and 500K resistors in the detector load circuit. Looking

carefully at the circuit, you can see where I've pencilled it in. This

type of connection is more of a sales gimmick than anything else. There

is no way to select between radio and gramophone, except by tuning off

station. There is some DC present at the terminals from the detector. Assuming

a magnetic pickup, which would have been common in 1948, this DC would

be largely shunted to earth. This would be avoided if the input was on

the other side of the 0.1uF; i.e. across the volume control pot.

Power Supply.

Despite being advertised for 12, 32, and

50V (and designated as such on the circuit diagram), there seems to be

no circuit for the 50V version. It is possible this never actually existed,

since outside of the telephone system, 50V lighting plants were much less

common. In fact, no Breville circuits for 50V were found in the Australian

Official Radio Service Manual. Just what design the 50V version would use

(if it existed) is unclear. 50V is high enough not to require a vibrator

power supply. The vibrator power supply as shown for the 742, used with

a dropping resistor for 32V, is not suitable for 50V.

A very faint possibility is the fictitious

50V set was just the 32V design with a resistor in series with the whole

set.

Looking at the 12V version first, the power

supply is conventional, using an Oak

V5258 12V synchronous vibrator. Breville have attached a label to the

vibrator, designating it as Breville No.4. This is interesting since the

V5258 is a standard type. It's possible Breville labelled it with their

own number to avoid the confusion of a 12V vibrator being used in a 32V

set.

The two dial lamps are 6.3V types, connected

in series across the 12V supply. The console version of the set has four

dial lamps, which are connected in two separate strings. Valve heaters

are connected in two series parallel branches. The ECH35, 6U7 and 6G8 heater

current adds up to 900mA for one branch. The 6V6 and remaining 6U7 draw

750mA, so a 45R resistor (R3) is added to bring this up to 900mA for the

other branch.

The 32V version uses the same 12V vibrator

power supply, but with a 20R resistor in series (R1). Assuming the power

supply draws 1A, this will drop 20V, allowing it to work from 32V.

However, this is an undesirable design,

because when the set is first switched on and the valves have not warmed

up, the B+ current is minimal. Thus, the input to the power supply will

be more than 12V. Apart from the timing capacitor not being the correct

value for this higher voltage, there is the danger of contact arcing in

the vibrator, along with stressed transformer and timing capacitor insulation.

A better scheme is to use a 32V vibrator transformer, but with a resistor

for the vibrator driving coil only. It was not until a few years

later that Oak vibrators became available in 24V and then 32V.

For 32V, all the dial lamps are in series

with an appropriate resistor (R2), depending on whether there are two or

four lamps. The valve heaters are all in series, but with all the 300mA

heaters in one group shunted with a 167R resistor (R4). This brings the

current up to 450mA so that the 6V6 can then be connected in series.

No fuse is provided, which is poor design. Should there be a short circuit or overload on the B+ supply, the vibrator and transformer are likely to be damaged. If the vibrator contacts weld together as a result, there will effectively be a short across the 12V supply.

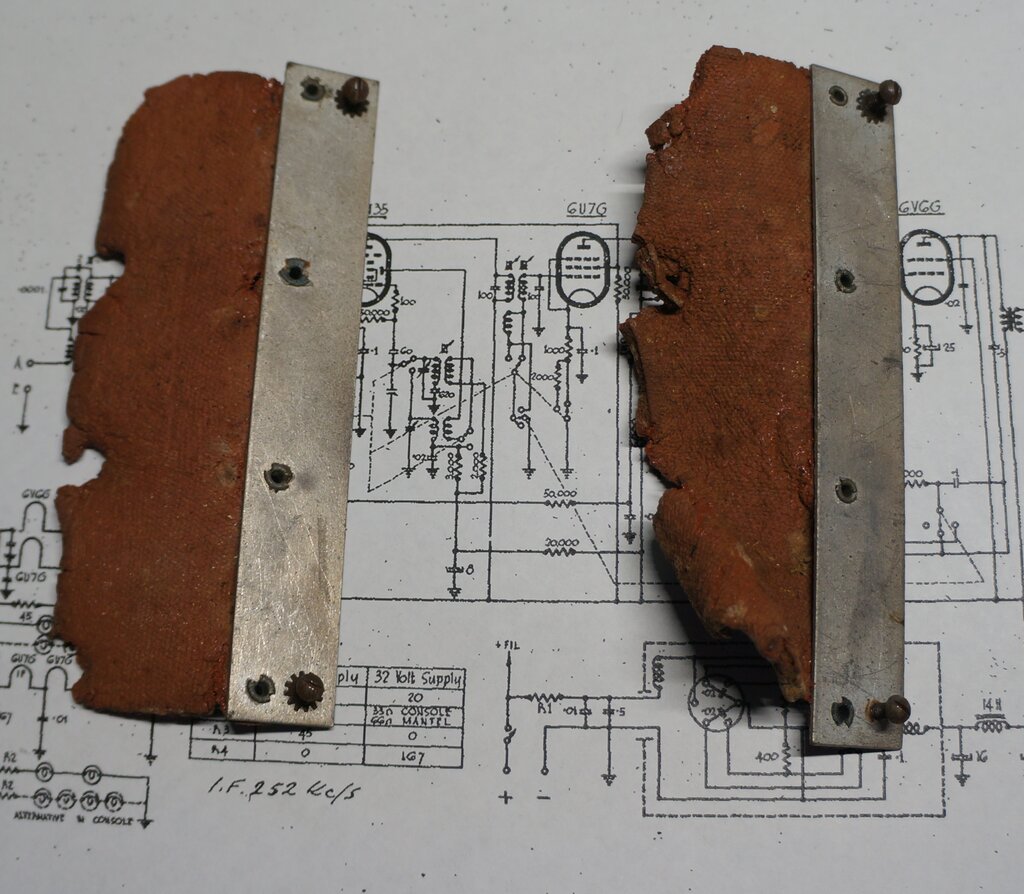

Rubber support strips were no longer usable.

I had some neoprene which was just the right thickness, and made a perfect replacement for the rubber. This was riveted to the chassis and the steel strips which attach to the box.

Neoprene replacement for the rubber strips.

The foam rubber supporting the vibrator

socket was in reasonable condition, but had deformed from years of the

vibrator's weight upon it. Simply removing it and mounting it upside down

was sufficient to give many more years out of it. Next was the electrical

restoration.

Applying 12V to the power supply produced

results straight away, which just goes to show the reliability of Oak vibrators.

The voltage was a bit low, at around 125V into a 240V 15W light bulb, but

bear in mind there is no filter capacitor in the supply itself. Also it

was quite possible the duty cycle of the vibrator had decreased.

The 400R primary damping resistors had

increased up to around 500R, so were replaced with 390R 1W. Since the 0.02uF

timing capacitors were mica, I decided to leave them. Had they been paper,

replacement would be essential.

The B+ RFC was open circuit, due to careless

replacement of the 0.1uF RF filter. The fine Litz wire had been damaged

near the solder tag of the choke. This was easily repaired.

The capacitor shown as 0.5uF from the

transformer primary centre tap to earth was an electrolytic of unknown

value (the paper label was damaged), and it did not look original. It measured

O/C, so replaced it with a 0.56uF polyester type.

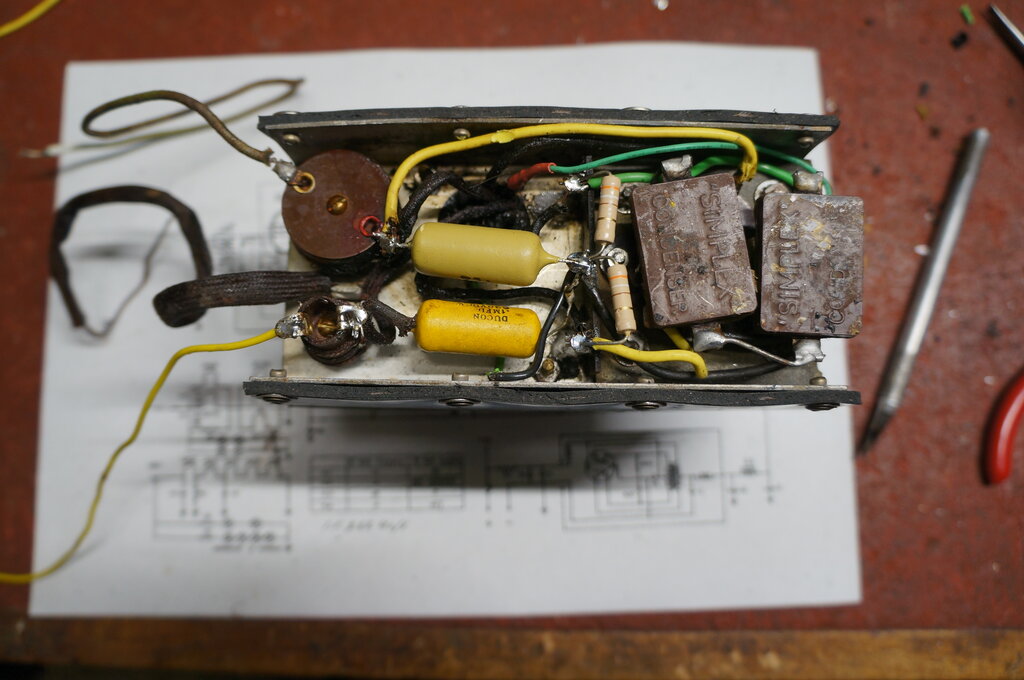

New capacitors and damping resistors. B+ RFC is at bottom left.

Additionally, the rubber wiring needed

replacement since it had gone brittle and was cracking. Particularly for

the connections to a floating vibrator socket, the wire should be very

flexible to reduce transmission of vibration to the chassis.

Next to restore was the vibrator itself.

While it was working, I could hear bits of brittle rubber rattling around

inside it, and the contacts were in need of cleaning and adjustment.

Stack support rotted away.

The base was removed and cleaned up. To

replace the rubber, I made two discs of adhesive foam rubber which is about

the right thickness. Then, a third disc is made up, but with a U section

cut out to slide over the bottom of the stack, and to cover the solder

tags.

The rubber inside the can at the top also

needed replacement. A felt disc was cut out for the top, and a strip of

the adhesive foam rubber to line the side of the can. It's important that

the vibrator mechanism can float, so there needs to be a gap between it

and the foam rubber. In this regard, felt is used right at the top, rather

than foam, since foam is too thick and will press against the top of the

coil.

New foam to support stack and insulate connecting wires.

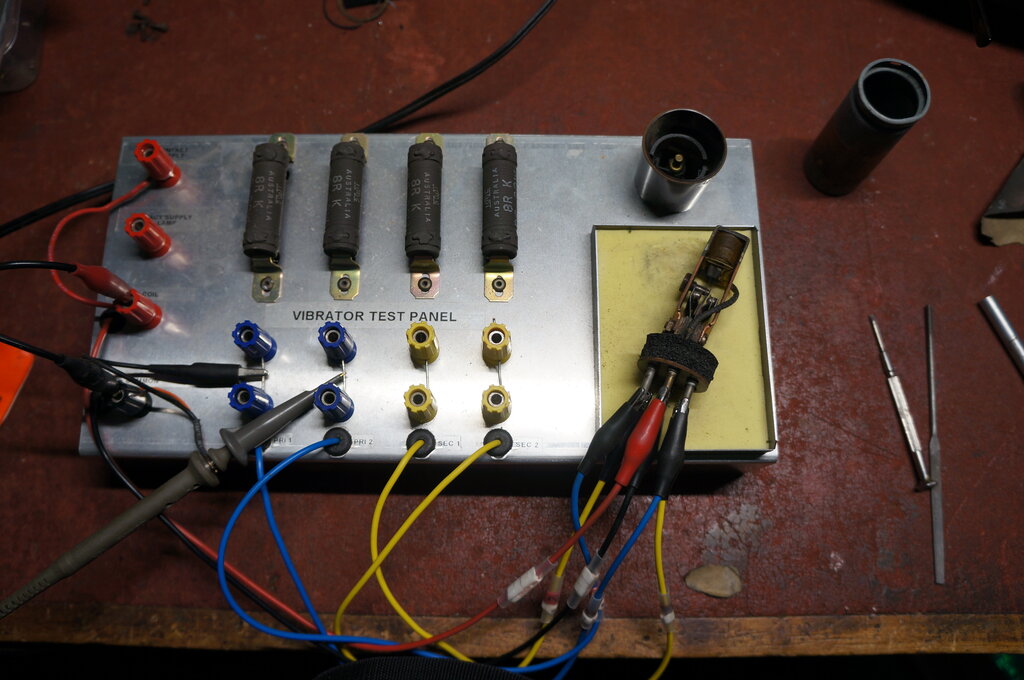

For checking the contacts, I used my vibrator test panel. The Oak vibrator has an 80% duty cycle, which for 100c/s, means a contact on time of 4ms. The secondary contacts need to be slightly less, at 3.8ms.

As suspected, the contacts needed to have

their duty cycle increased. The vibrator had been well used, and years

of hammering had spread the contacts. The jagged waveform indicated cleaning

was also needed, and I simply used a jeweller's file.

The result is not perfect, with a points

file being preferred. However, the thickness of the points file requires

the vibrator be disassembled. For a low power unit like this, it was quite

good enough.

Heathkit

vibrator tester tests under normal operating conditions.

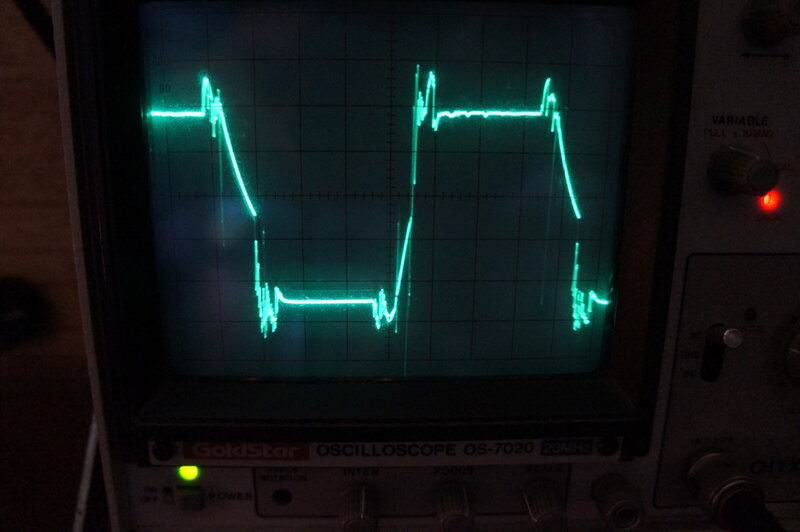

Primary waveform in the set. The peaks at the edges are due to this

being a synchronous vibrator. We can clearly see the secondary contacts

are closing after, and opening before the primary contacts, which is as

it should be.

Final check to see no sparking at the contacts. Camera caught the

reed on on the pull swing.

With the vibrator supply restored, the B+ was up around 160V. While less than the usual 250V the valves are rated for, the lower B+ means a substantial reduction in battery current. Additionally, the 6V6 is over biassed to further reduce B+ current. Audio output is still more than sufficient for a domestic radio.

The supply was reinstalled on the radio

chassis,

reconnected and powered up. Of course, I'm aware of all the old capacitors

in situ, but I was keeping an eye on the current draw. As it happened,

there was nothing apart from the buzz of the vibrator and presence of B+.

In fact, the current draw was no more

than when I was testing the supply with no load.

Blown Valves.

And here we come to a very sad fact about

radios designed for low voltage lighting plants. Most surviving examples

have been plugged into 240V out of ignorance. The thought that a radio

might operate at something besides 240V escapes the typical person, curious

to see if the radio works. Battery and 4 or 6V vibrator sets have a better

chance, since crocodile clips or battery plugs with multiple wires, force

the curious person to think otherwise. Nevertheless, there is a danger

with 6V vibrator sets being connected to a 12V car battery. Fortunately,

both my 6V vibrator sets weren't damaged thus, but my 32V "Standard" wasn't

so lucky.

Sets for home lighting plants are fitted

with the same kind of two core cable as one uses with 240V appliances,

and in most instances, a three pin 240V plug was also fitted. While many

sets are labelled as to their voltage, this is conveniently ignored, and

the presence of a three pin plug entices the ignorant to apply 240V.

The end result is a blown set of valves

and dial lamps. If you want to restore sets for lighting plants, expect

to replace lots of valves!

The Breville was no exception, with all

valves but one of the 6U7's blown open circuit. How the vibrator survived,

I do not know. I can only assume a fast responding circuit breaker. Incidentally,

this is another good reason to include a fuse inside the set.

Interestingly, there was an EBF39 in the

ECH35 socket. Had it not been damaged, it could have been used to replace

the 6G8.

Anyway, a look through my valve collection

provided replacements for the 6U7, ECH35, 6G8, and 6V6.

At this point, all valves lit up, but there

was still no audio. The 6V6 grid was responsive, but not the 6G8. No voltage

was present at the 6G8 cathode pin, and its plate voltage was almost the

full B+. Obviously, the 6G8 wasn't drawing current, despite screen and

plate voltage.

I tried another 6G8 and the set came to

life. Not surprisingly, the 6V6 grid was positive, so first thing was to

replace the grid coupler (0.01uF), so as not to ruin the valve, and also

to reduce the B+ current, allowing a bit more voltage from the power supply.

The 6G8 I previously tried responded to

a resolder of the cathode pin, and went back in. How many perfectly good

bakelite base valves have been thrown out because of a dry jointed pin?

With the set basically working, now was the time to go through and re-cap and re-resistor it. The only paper capacitors left were those across the 12V supply, and cathode bypasses. The B+ electrolytics were all OK and left, but the audio bypasses were open circuit. Replacing them brought the gain up by a useful amount. The only tricky part of this was replacing capacitors around the front end coils and the wavechange switch, but with care and dexterity was completed without too much of a challenge. Aside from the 6G8 plate resistor, the rest were close enough and not replaced.

Under chassis complete. Note fuse at bottom right.

The lack of valve shielding did not appear

problematic. The 6G8 and one of the 6U7's are missing their Goat shields,

and the ECH35 has lost a lot of its metallic paint used for the same purpose.

There's no sign of instability, so have not worried about it.

Final under chassis work was to replace

the power cable with polarised plug, and install a 5A fuse. For the power

cable, I used Jaycar WB-1754. This is a two core cable with black and red

conductors, and a black outer sheath. One could install a zener diode after

the fuse to protect against the application of 240V. It must be noted that

the 12V supply needs to be polarised correctly because of the synchronous

vibrator. If input polarity is reversed, so is B+ output polarity. While

the valves are not harmed by this, the electrolytic capacitors will draw

excess current and may break down.

Polarised plug for use on 12V.

Dial Lamps.

The 742 was run for several days with

complete reliability. The final thing was to deal with the missing dial

lamps. There are two steel strips spot welded to the back of the dial,

which looked like they were made for the ubiquitous push on E10 lamp socket

used on most Australian radios. It quickly became apparent that they weren't

meant to be used this way, with the length and position being quite unsuitable.

It's been many years since I restored the 730 and could not remember its

dial lamp set up. Luckily, the 730 was described in Silicon Chip, and from

what I could see of the photos, the dial lamps were actually in a kind

of reflector sub assembly, which pushed onto the two metal strips. Fabricating

such a thing is well within my capabilities, but the question was how to

attach it to the metal strips. This wasn't clear in the photos, and it

did look like they had used the spring clip in the light sockets. But,

for the kind of sockets I had this wasn't going to work.

Did we really need the reflector? Testing

a 6.3V bulb at the top of the dial with the chassis in the cabinet worked

perfectly with good even dial illumination. The simple way out of the problem

was to shorten the metal strips, and bend them 90 degrees. The bulbs would

then be just at the top of the dial. I used 250mA dial lamps.

Dial lamps mounted at the top of the dial.

The result was completely successful.

Chassis back in cabinet. "When replacement vibrator is required..."

- that's a bit pessimistic. On the contrary, this set has the original

vibrator in good condition, and it's been well used.

The screws and washers to secure the chassis

in the cabinet were missing, as were the back screws on the chassis securing

rails. I could have retapped them to take 4mm screws, but I found some

of the correct thread. I would have assumed they were a BA or Whitworth

thread, but could not match them to anything I had.

Testing the 6U7.

Increasing the heater to 9.3V did bring

up emission and transconductance to a reasonable level. It would appear

that this 6U7 was just very worn out, or had perhaps been damaged from

the excess heater voltage that burned out all the other valves. In view

of the

much higher gain, I replaced the shield

on the replacement 6U7.

Dead parts from the 742.

Sound quality is excellent, as would be

expected from a baffled 8" speaker, and an audio amplifier with feedback.

There is no vibrator interference, but the negative side of the 12V supply

needs to be earthed.

Current draw at 12V is 2.1A.

More Faults.

For the testing, I had been listening

to the mid and low end of the MW band. Out of curiousity, when I tuned

to the high frequency end of the band, the sensitivity suddenly disappeared

around 1350Kc/s. It wasn't the common fault of shorting tuning condenser

plates, since the drop off was not sudden. It was obviously the local oscillator

dropping out. On short wave, I discovered the same thing, except the gang

didn't have to be opened quite as much for the oscillator to drop out.

What could cause this? There's not a lot

of components in the local oscillator circuit; the grid leak components,

the coil, and the tuning and trimmer condensers. My initial thought was

the grid condenser could be faulty, since I have had that before. Alas,

even at 500V it tested perfect. Nevertheless, I temporarily installed a

parallel pair of 33pF ceramic capacitors instead. The fault was the same.

The resistors were all OK. I even tried putting the full B+ on the oscillator

supply, but the improvement was only minor.

Despite the good gain of the hexode section

of the ECH35, maybe the triode was faulty. I had a 6J8 conveniently to

hand, so plugged that in. Up came the local oscillator - and right across

the band this time. Not only that, it was working across the short wave

band as well.

Sure enough, testing the ECH35 revealed

a good hexode section, but the triode was very weak. Yet another ECH35

was taken from my collection, and this time it worked as it should.

With complete band coverage, the set seemed to be working well. That is, until the volume was turned right up. I could hear instability or oscillation in the audio. Maybe the 6G8 really did need shielding. I tried that, but no difference. Another possibilty is one of the B+ electrolytics was faulty. That was the next thing I tested. There was a few volts of audio ripple on the B+ supply, which disappeared when another capacitor was bridged across it. Not only that, bridging the supply with the extra capacitor stopped the instability and brought a further improvement in the audio quality, particularly with the bass response. The 16uF second filter capacitor (shown as 8uF in the circuit) was therefore replaced, fixing that fault.

All during the restoration and testing, the IF amplifier 6U7 would intermittently stop working. This is the valve I resoldered the cathode pin on. Tapping on the side would restore reception for a time, but it would always fail again. Next, I tried resoldering all the base pins, but there was no improvement. I could only conclude there was an internal break in one of the connections inside the valve. Replacing it finally fixed it. I used a VR100 since I have more of them than 6U7's, and one happened to be in the first valve box I looked in.