This 1935 model car radio was bought at

a swap meet in the mid 2000's. At the time, I was not able to identify

it as a Detrola, as the only badge, "Motoradio" did not appear on the nostalgia-air

site. However, in recent times with another look, I noticed the top

cover badge had on it, "Made in USA by D.R. Co". Since having acquired

another

Detrola (model 297) only a few years ago, I recognised the D.R. as

Detrola Radio. Some time searching through diagrams on nostalgia-air brought

forth a circuit which matched. It was model 6R. This is the same as the

listed 6M, except the 6R has no tone control. Having identified the model,

another search through other car radio listings showed it to be a 1935

model. From the valve types and general style, I had already assumed it

to be around this age, but now I had a definite year.

Like most car radios of this era, the

radio itself is a large box mounted on the firewall. The speaker is internal,

and the controls are remote, operated via Bowden cables from a small control

unit mounted on the steering column or dashboard. Being of U.S. manufacture,

it is of course for 6V operation.

See the Detrola operating here https://www.youtube.com/watch?v=6BNWYmkD6vc&feature=youtu.be

and here https://youtu.be/PQdPxCgbC5s

Patent plate attached to top of cabinet. Note at the bottom it says

"Made in U.S.A by D.R. Co.".

Rare in Australia.

Car radios of this age are extremely rare

in Australia. The conservative radio industry here did virtually nothing

to promote car radios, pre WW2, and in any case their high cost meant that

they were a luxury item. While it is true that car ownership in Australia

was also very low, of the cars that did exist (and a surprising number

have survived) hardly any were fitted with radios. Even post-war,

few radio manufacturers, with the notable exceptions of Astor, Ferris,

and AWA, had much enthusiasm for producing car radios. This state of affairs

lasted until the 1970's when Japanese imported cars were being sold with

radios included. This forced local car manufacturers to reluctantly include

heaters, radios, and clocks in their own models as standard accessories.

The result is that valve car radios are

relatively uncommon in Australia, especially pre-war models. This is quite

different to the U.S. where they became a standard fitment to post-war

cars.

How this 6R came to be in Australia is

unknown. One could assume that it came in a car imported from the U.S.,

although the import tariffs and the right hand drive requirement discouraged

this practice. Certainly, U.S. made radios were not sold on their own in

Australia because of import tariffs. Perhaps one of the more commonly imported

Canadian cars was the source of this radio?

Examination of the 6R.

Not surprisingly, the control head was

missing. One is doing well if a car radio appears with its Bowden cables

and control head. And, with single unit sets, you're doing well just to

get a dial. You've hit the jackpot if you get the escutcheon and

the knobs! My plan therefore, was just to use the radio as a kind of "picnic

portable", with control knobs on the set itself. The idea would be to sit

it on the running board of the Model T for listening, while stopped somewhere,

and to connect it to the battery by a lead and clips.

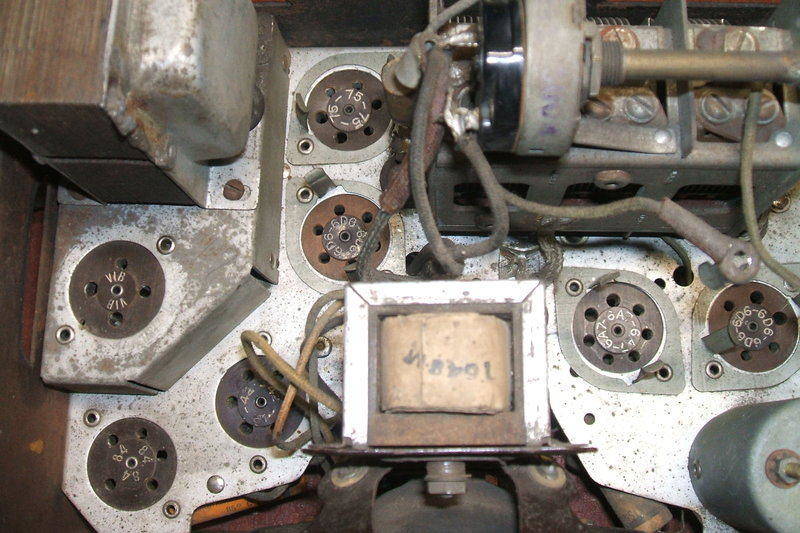

Inside the set, all the valves were present,

but the Goat shields were all missing except for one. The vibrator was

also missing. Otherwise, everything looked good.

I thought it was a nice well thought out

touch to have the valve type numbers actually stamped into the valve sockets.

Type numbers stamped into the valve sockets makes things easy for

non technical types who wish to get all the valves tested, and of course

for future collectors!

Under the chassis it looked as though there

had been no servicing since the 1940's.

Despite the original appearance of these old condensers, the radio

had actually been recapped in the 1940's. Note the two holes in the coil

can at the right. These allow access to the tuning condenser mounting screws

- once the coil is removed from the can, which involves removing the entire

chassis from the case.

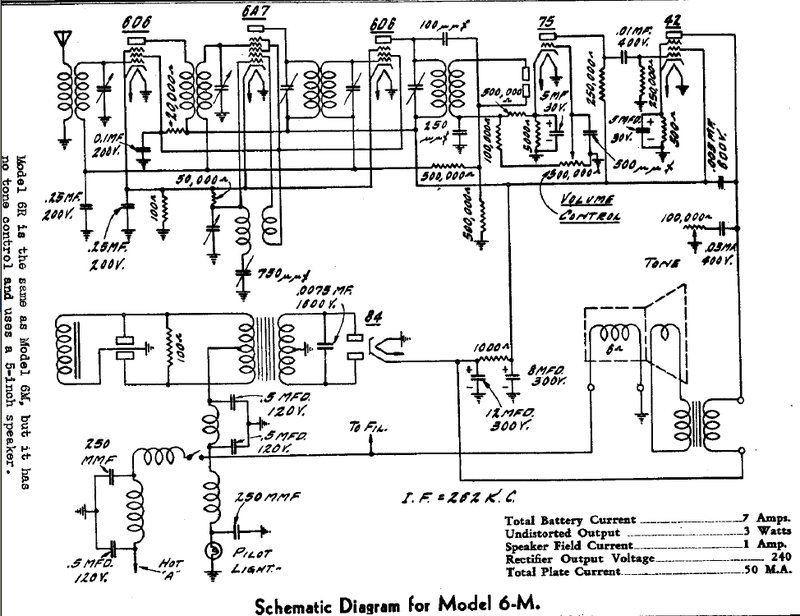

The 6R is a standard 6 valve superhet. There is a .01uF between the 100K and volume control which is not shown. Also missing is a .1uF B+ bypass.

There is nothing much unusual about the

circuit. The aerial coil feeds a 6D6 RF amplifier, which in turn feeds

the input of a 6A7 pentagrid converter. As the oscillator coil (also the

aerial and RF coil) is not adjustable, a variable padder condenser allows

correct tracking between the RF and oscillator circuits, to produce a 262

kc/s IF. This choice of IF might seem strange to the modern enthusiast,

but was quite common with portables and car radios. The advantage is higher

gain than would be provided with a 455 kc/s IF amplifier.

Selectivity is also improved, but the

image rejection is not as good. This is not important here where the RF

amplifier is tuned. It is for this reason that the 175 kc/s IF fell out

of favour. In strong signal areas, stations might appear at two points

of the dial with such sets, unless they had a TRF stage or preselector.

The IF amplifier is another 6D6 remote

cut off pentode. The IF transformers are air cored types adjusted by trimmer

condensers. Interestingly, the secondary of the second IF transformer is

untuned. One wonders if the loss of gain here is important. The secondary

feeds one diode of the 75 for demodulation, where the audio proceeds to

the volume control, and then the grid of the 75 triode. The other 75 diode

is shunt fed from the primary of the second IF transformer to provide the

AVC voltage.

The first three valves, 6D6, 6A7, 6D6,

all use a common bias resistor of 100 ohms. This saves having to have 300

ohm resistors, and associated bypass condensers for each valve.

Similarly, their screen grids are all

fed via a common 20K resistor from the B+.

The output valve is a 42 pentode used

in the normal way. The choice of bias resistor bypass condenser seems rather

low for the 42 and 75 valves. At only 5uF, the bypass for low frequency

audio signals will be poor, resulting in a sound with more treble than

would be normal. Perhaps this was intended for intelligibility in a moving

car, with road and engine noise competing with the radio.

The tone control is only part of the 6M,

and not the 6R. It's a simple variable top cut control.

The speaker is a 5" electrodyamic type,

with the field coil energised from the 6V supply. This is more efficient

than the conventional method of using the B+ current flow to energise it,

and makes things easier for the vibrator power supply.

By 1935, B+ batteries or genemotors were

obsolete for car radio use, so of course a vibrator power supply provides

the B+. It is interesting to note that this set was made only two years

after the full wave vibrator had become standard. The circuit here is completely

conventional, with a .0075uF buffer condenser to tune the transformer to

the vibrator, and a 100 ohm damping resistor across the primary. An 84

rectifier provides the B+ from the transformer. This valve was developed

for car sets (domestic sets remained using 5V directly heated valves such

as 80 for quite a few years), because for car radio service an indirectly

heated cathode is required. While one could run an 80 heater off

the vibrator transformer, efficiency would be considerably reduced, and

such an increase in load (an extra 10W) would be undesirable for the vibrator.

The 84 soon became known as the 6Z4 with the RMA numbering system. When

octal bases appeared, it then became the 6X5, and then the later 7 pin

miniature 6X4.

A simple resistive filter with two electrolytics

provides a reasonably clean B+ at 240V. The 1000 ohm filter resistor is

riveted to the chassis for heatsinking.

For the 6V input, the usual array of air

cored chokes and bypass condensers filters out vibrator interference, and

any incoming electrical system interference on the car supply.

Aerial, pilot light, and the 6V input connectors are of a bayonet type common to car radios. While they look remarkably like that of an MBC dial lamp base, the diameter is unfortunately not the same.

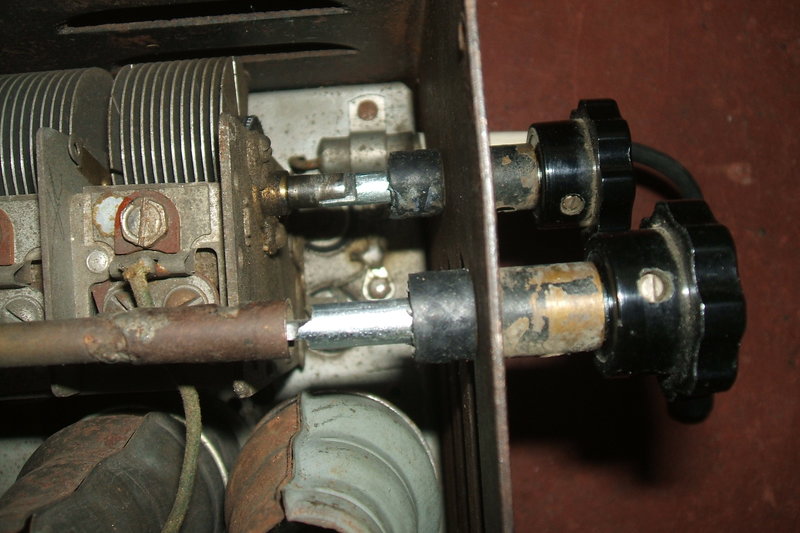

The first obvious problem was that the

tuning condenser and volume control shafts weren't lining up with the two

Bowden cable attachments on the side of the cabinet. The reason was the

rubber grommets, on which the tuning condenser is mounted, had hardened

up and partially decomposed. I'm not sure why so many manufacturers mount

their tuning condensers on rubber grommets when they are operated by a

dial cord. It's not as if they need to be electrically or mechanically

isolated from the chassis, but in this case, some mechanical give is desirable

because of the direct connection with the Bowden cables, to prevent binding

as the shaft is rotated.

The first hurdle was to replace these

three grommets. And here I saw the first, let's shall we say, less than

desirable aspect of servicing this set. Understandably, car radios are

of compact construction, but really, having to remove the aerial coil from

its can to get at the tuning condenser screws is pushing things too far.

Not only that, to get the coil out of the can, the chassis has to be removed

from the case, along with the speaker. Fortunately, removing a number of

screws allows the chassis to simply fall out of the case, giving the improved

access.

Having desoldered the aerial coil wires

and extracted it from the can, we now had access to the front condenser

mounting screws and grommets. I had just the right size for replacement

and proceeded to install them. Alas, the shafts still didn't line up. I

really wondered how they ever did...

Eventually, after much experimentation,

I found packing up one foot with a washer tilted the tuning condenser so

that mechanical alignment was acceptable.

New Controls.

Next was to make up the new control shafts.

Fortunately, the Bowden cable receptacles were 1/4" diameter. This meant

I could cut down a piece of 1/4" rod to make the shafts, and they would

fit normal knobs with no further work. Making the new shafts was all straightforward,

but the ends had to be filed into a slot, so as to engage to the

existing controls. Sections of 1/4" fuel hose were pushed over the shafts

to retain them in place.

Once this was done and suitable knobs

were fitted it was time for the electrical restoration.

How to use a radio with no Bowden cables.

Strange things...

It quickly became apparent that this radio

had been recapped in the past, and by the appearance of the "new" types,

I would say mid to late 1940's. When we talk about recapping a radio in

the modern day, it's to replace all the paper condensers with polyester

types to forever eliminate the leakage problem inherent to paper types.

However, recapping 1940's style was with...paper types! Whoever had done

the job had simply cut off the old components at the valve sockets, and

soldered the new components on top of the old lead ends.

That always smacks of a lazy rush job

for profit rather than good workmanship. However, in this set it wasn't

very difficult to remove the lead ends...not like certain Australian manufactures

who loved winding leads as many times as they could through the tags before

there was no room, and then crimping them tight with pliers just to make

sure. But, in this case it did leave useful clues as to the radio's past.

As I worked through the resistors and capacitors, I found some rather odd things which made me question the knowledge of the serviceman. Not that the things done would prevent the radio working, they were just very weird, and one "repair" would have caused short vibrator life.

Normally, low value resistors are quite stable and almost never need replacing. Not the Micamold types used here though... The 100R cathode resistor for the front end valves measured 260R. The 42 cathode resistor, which should be 500 ohms was measuring 1000 ohms. While these changes in values would not stop the radio working, sensitivity and power output would be reduced.

The 75 plate resistor was 500K, and it appeared to be the original. This is at odds with the circuit (and conventional practice) of using 250K. While 500K can be used in some situations, this was definitely not one - the 42 grid resistor was 250K, not only in the set, but on the circuit diagram. While 250K seems low for an output valve grid resistor, it's actually good design for a car radio. This is because with the higher temperatures of car sets, caused not only by the ambient heat of parking a car in the sun, but also by the cathodes running at higher temperature than they do in domestic sets. This is because of the car electrical system being at least 7V instead of 6.3V, with the engine running at speed. High grid resistors like 500K or 1M increase the chances of grid emission, which will eventually ruin the valve, as well as overload the power supply.

The problem here was that 500K is unsuitable as the preceding plate load. For maximum power transfer, the following grid resistor must be equal to or higher than the preceding plate resistor. Obviously, the radio would have worked, but just not optimally. The 500K plate load had gone high anyway, so I replaced it with a new 220K.

There was a .01uF in series with the volume control input which was not shown on the circuit. It's actually correct to have this, so that the track of the volume pot does not have DC flowing through it. Thus, I replaced the condenser. Further, there would have been more DC loading of the detector with the circuit as drawn, which is not desirable for distortion.

Condensers.

There was also a .1uF B+ bypass in the

set, not shown on the circuit. It was impossible to tell if there was originally

one before the recap, but as it's the correct thing to do, I replaced it.

Just the 2nd filter electrolytic cannot be relied on because it is ineffective

as a bypass at RF. Leaving out the .1uF B+ bypass is a favourite cost cutting

measure with many manufacturers, but it means the radio becomes unstable

as the electrolytics age.

There were two 1940's style Aerovox 8uF

450V electrolytics; obvious replacements, which I had just assumed to be

the first and second filters. Not so! To add to the bizarre situation,

the first filter turned out to be a 4uF 450V! As you can see from the circuit,

it was originally 12uF. The second filter was indeed one of the Aerovoxes,

but what was the second Aerovox for? What else but the 42 cathode bypass!

Yes, an expensive and large 450V capacitor with only about 13V ever across

it. Ironically, that 4uF used for the first filter was closer in value

to the original 5uF 42 cathode bypass, even though, again, the 450V rating

is ridiculously high.

Given my success with some American 1940's

electrolytics, I thought I'd see if the two Aerovoxes could be reformed.

Indeed, they responded well and they were retained, but in the correct

positions this time!

The 5uF 75 cathode bypass was not usable

- the negative lead had detached from the aluminium foil.

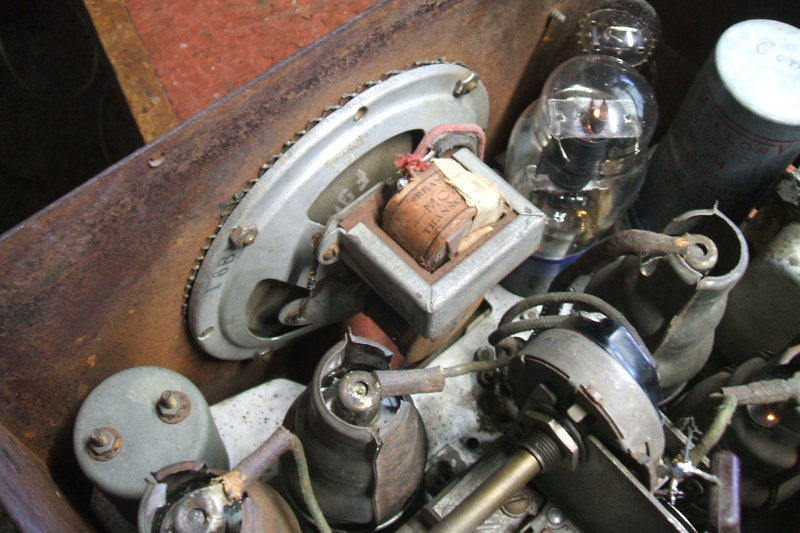

The vibrator sub-chassis. The two .5uF's and choke are visible for

the 6V supply. To the left is the Micamold 100R resistor across the vibrator

socket. Strangely, the buffer condenser I'd expected to see wasn't here.

Getting it out involved desoldering the

short 6V supply wire, and then the equally short rectifier socket wires

for the AC, and then finally a short length of earth braid. After that,

three nuts had to be removed, one inconveniently mounted under some leads

attached to a tagstrip sharing the same nut. It was just easier to do this

with the chassis out of the cabinet, so again the cabinet had to be lifted

off and the speaker removed.

Once removed, I was surprised to see no

buffer condenser; just the the two 6V filter condensers. Where else could

it be? A closer look at the rectifier socket solved that mystery.

No Buffer.

Yes, some idiot had simply chopped out

the buffer - its lead ends were still wrapped around the socket pins. The

radio would have been going through vibrators at a rapid rate, leaving

the owner to think vibrators are unreliable. Here we have a classic example

of an abused vibrator power supply. Yes, the radio will work without, but

with high peak voltages across the contacts, especially before warm up,

and no tuning of the transformer, the contacts will wear rapidly. It's

also quite possible for the transformer and rectifier and rectifier socket

to be damaged by the high peak voltages due to this mistreatment.

While the subchassis was out, I checked

the 100R damping resistor. As it was also a Micamold, I wasn't surprised

to see it had risen to 200R, so it was replaced. As the .5uF's are across

the 6V supply, any leakage was not important, so they stayed. As can be

seen from the photo, their leads are braided wire to provide a low inductance

connection.

I noted that the vibrator socket was wired

for a shunt drive type. Pin 4 had also been earthed. This pin is normally

not connected with most shunt drive vibrators, but there are a very few

where pin 4 is the reed instead of the usual pin 1. Presumably this was

done to allow a greater choice of vibrator types.

So with a missing vibrator, what to replace

it with? Of course, I could have used any of the 6V four pin vibrators

in my collection, but in my catalogs, the Detrola 6R was listed, along

with the Radiart and Mallory types recommended. It just so happened I had

the Mallory type, a 294, so that's what went in. The catalogs also confirmed

the buffer being .0075uF.

A brief check of the 294 contacts confirmed

all was good, which I pretty much expected from a Mallory that hadn't been

abused in its previous life.

Mallory 294 installed and ready to go.

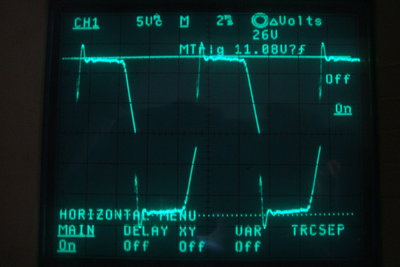

What to use for the buffer? .0075uF is not a preferred value, so I had nothing modern. I could have used two .015uF's in series, but it just so happened I had some .0082uF 1600V types. These were intended for tuning colour TV line output stages, so are perfect for this kind of application. As I've pointed out elsewhere, while the buffer value is very important, it is not generally problematic going up slightly in value. I did try both values to confirm (most important!), and the difference between .0075uF and .0082uF was indiscernible on the CRO waveform. Certainly, vibrator power supplies must always be checked with a CRO when restoring them. Differences between vibrators can mean a buffer ideal for one is unsuitable for another, among other things.

No load vibrator waveforms, at left with only the .0082uF buffer,

and at right with a 5.6K series damping resistor.

I noticed there was some overshoot, and this was almost eliminated with a 5.6K damping resistor in series with the buffer. If I was to be pedantic, I would have included the 5.6K but as it was not convenient to mount, and the overshoot did not seem problematic, I did not include it.

At this point with the 294 happily buzzing away and producing the correct waveform it was time to reassemble everything.

Fully recapped. Note the yellow condenser in the top left corner

- note that there was nothing there in the previous unrestored photo -

it's the buffer.

The final collection of replaced components.

Now, there were signs of life, although

rather lacking. The gain was terrible, with only the strong 50kW ABC 2BL

and 2FC transmitters receivable. The rest of Sydney's MW stations

were so weak and masked by noise to be of no entertainment value at all.

This was obviously not right, not only for a car radio, but one with an

RF stage.

Aside from that, was the absolutely awful

distortion from the speaker. I can't recall anything so hideously sounding.

Noting that most of the Goat shields were missing from the valves, I replaced them, and then tested the alignment. The IF channel did need a slight tweak to bring it all up to 262 kc/s, and likewise the front end, but it wasn't much better. In fact, the distortion from the speaker put me off working on it. How could I describe it? As I'd approach the set on my bench I'd think twice about switching it on - for I knew what I'd hear when it warmed up. And, that was not nice!

Vibrator stops.

A peculiar thing became evident around

this time, in that the vibrator would stop when I tilted the set a certain

way, and the 6V current went up. It wasn't the vibrator, because connected

with flexible wires to my current limited power supply, I could hold it

in any position and it kept running.

This meant only one thing...out with the

vibrator sub chassis - yet again, and all the work that entails. And there

was the problem - or so I thought. A loose screw left in the set used to

hold down the original filter electrolytics. It was jammed in between one

of the 6V tags on the tagstrip so it was also touching the chassis. I reinstalled

the subchassis and tried again.

Well, yes it seemed ok, but then it happened

again. This time the current dropped.

Again, the vibrator ran fine externally

to the set. So, for the 3rd time, the subchassis came out. I found

pushing the vibrator in its socket one way would cause the fault. Something

to do with the socket then? It turned out that the earth connection had

broken where it was soldered to the chassis. There wasn't much flexibility

in the tinned copper wire, and the reality is the socket flexes when the

vibrator is removed or inserted. Once the wire was replaced there was no

further trouble.

IF Oscillation.

In the meantime, an oscillation had developed.

By removing the 6D6 RF amplifier and 6A7, I found it to be the IF amplifier

oscillating. This led me to find the 6D6 IF valve's Goat shield was not

earthed properly. The two spring contacts coming up from the chassis are

not particularly effective.

Speaker.

The speaker is not designed to be taken

apart, like many of its age were. The distortion seemed to be a problem

of voice coil misalignment, because by pressing on the cone in certain

directions, the sound would improve. There appeared to be limited adjustment

in voice coil centering by means of cardboard strips clamped under screws

at opposite sides of the speaker frame. Alas, the adjustment available

here made no improvement.

I took the speaker out, powered the field

coil from 6V, and connected a tape recorder to it for an audio source,

hoping that maybe just the frame needed to be bent into a certain position

to realign the voice coil. It seemed better, so put it back in the radio.

Annoying crackle.

Not a lot better at all. I also noticed

an annoying vibration sensitive crackle whenever the chassis was touched.

The 6V current draw fluctuated slightly in time with the crackle.

Eventually, I narrowed it down to the

42 socket. Even after tightening the socket pins and cleaning the 42 pins

with CRC. the crackle was still there.

Finally, I resoldered the pins on the

42 itself, and that was fixed.

The speaker - again!

Either the speaker had to be repaired,

or I would have to replace it. I'd rather not replace it because it would

mean using a more modern permanent magnet type which would look out of

place, and reduce the radio's character. After all, it's not like every

radio has a 6V electrodynamic speaker.

With nothing to lose, I removed the cone

and then the dust cover around the voice coil. It actually came apart easily

as the old glue was quite brittle. And here I found the cause of the problem,

which no amount of voice coil centering adjustment would have ever fixed.

Swollen voice coil former was the cause of the hideous distortion.

Here, I've already scraped most of it away.

Something had caused the voice coil former to have swollen and increase in thickness. No wonder it was rubbing on the magnet. I scraped the extra thickness off and it seemed to fit better back in the magnet assembly.

The method of voice coil centering is evident here.

Speaker frame without the cone.

Waiting for the cement to dry.

I used Permatex No.4 gasket cement to glue it all back together. A small rattly sounding tear in the cone was repaired with contact cement. Connected again to the tape recorder, it actually didn't sound too bad once the voice coil was centered. In fact, it was what an old electrodynamic speaker usually sounds like.

Replacement Speaker.

Alas, after about an hour of listening

the problem was back. With the heat of the field coil (6W), and the heat

from inside the set itself, the speaker frame warped enough to cause the

voice coil to get out of alignment again. Evidently, I hadn't cleaned up

the voice coil former enough. At this point I gave up, and installed a

locally made permag Rola. It looked sufficiently old enough with its Bramco

output transformer. In fact, it worked out very well - Australian made

components being ten years behind the U.S., means that the 1940's speaker

looks just right in a U.S. made 1930's set. Importantly, I now had a radio

I could listen to.

Replacement 5" Rola with Bramco output transformer.

Front end alignment.

Having dealt with the awful distortion,

the front end problem could be dealt with. The radio lacked gain to the

point where it was actually no better than a crystal set. On top of that

was the worst interference I can recall from any set that I've worked on.

The only thing to do in this situation

is to start with the IF alignment again, then the RF and local oscillator

alignment, and also the padder condenser adjustment.

However, the IF adjustment was minor and

did nothing to improve sensitivity.

At this time, I discovered the screen

voltage for the front end valves was only about 50V. I had noted the screen

resistor (20K) was a bit high when recapping the set, but didn't think

it too important. But, with the gain so poor it was time to look at it

again. From memory, the screen grids should be closer to 100V, and I confirmed

this by looking up the valve data.

I changed the resistor, but instead of

using 22K as the preferred value, I used 18K instead to get a bit more

gain. Now the voltage was up to around 75 and the improvement was noticeable.

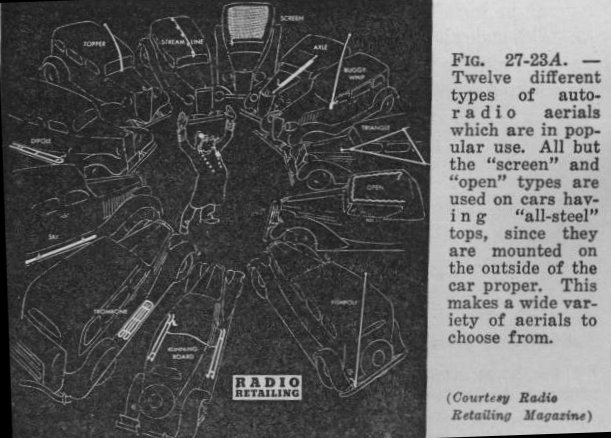

In the mid 1930's, the types of car radio

aerial in use were of various types. The modern telescopic aerial wasn't

standard until post war - popularised by aerials used on military vehicles.

With no information on what kind of aerial

the Detrola was meant to be used with, it meant I had nothing to go on

in terms of how to align the aerial coil, or if it would even peak up with

the aerial I wanted to use - a modern telescopic type.

Types of aerial in use in 1935. What did the Detrola use?

All I could do was try it. As it turned out, the RF and local oscillator alignment was way out; more so than what I had assumed with my first rough alignment. The set wasn't able to tune much past about 1300kc/s. Like other sets this age, the only adjustment is the trimmer condensers, which really only affect the high frequency end of the band. One has to rely on the coils being matched during manufacture, in order that the low end alignment is satisfactory. Once I was happy with the band coverage, which I set for 550 to 1600kc/s, then the padder was adjusted in the middle of the band to get the best compromise with local oscillator tracking.

With that done, the gain was much higher,

and stations could be received just by placing my hand near the grid leads

of the RF and converter valves.

However, all along, since I first powered

up the radio, there was an awful interference present from about 800kc/s

to 1500kc/s. This was not making sense, because with no aerial plugged

in, the radio was silent, except for the usual white noise generated by

any high gain circuit. This ruled out anything inside the radio being the

cause, or anything coming through the 6V supply. It just had to be something

outside.

With a tuned loop aerial, freedom from

interference was considerably better. This indicated the interference must

be more electrostatic than electromagnetic. But why did other radios in

the same room not suffer like this? That is still not understood, and I'm

putting it down to some characteristic of the aerial coil being perhaps

self resonant at a particular frequency, or some other thing like a particular

input impedance.

Just because this all seemed so illogical,

I decided I'd run the set off a battery, away from the house and anything

electrical that could cause interference. I took the set out to the garage

and connected it to the Model T battery. The difference was amazing! It

was really like night and day. The Detrola was as quiet as you could wish

for, and not only all Sydney stations receivable clearly, but so was 2LT.

This station has directional characteristics which result in a very weak

signal to the east - where I am. It's always a good way to test sensitivity

during daylight hours.

The problem wasn't really a problem after

all, and the Detrola now works as it should.