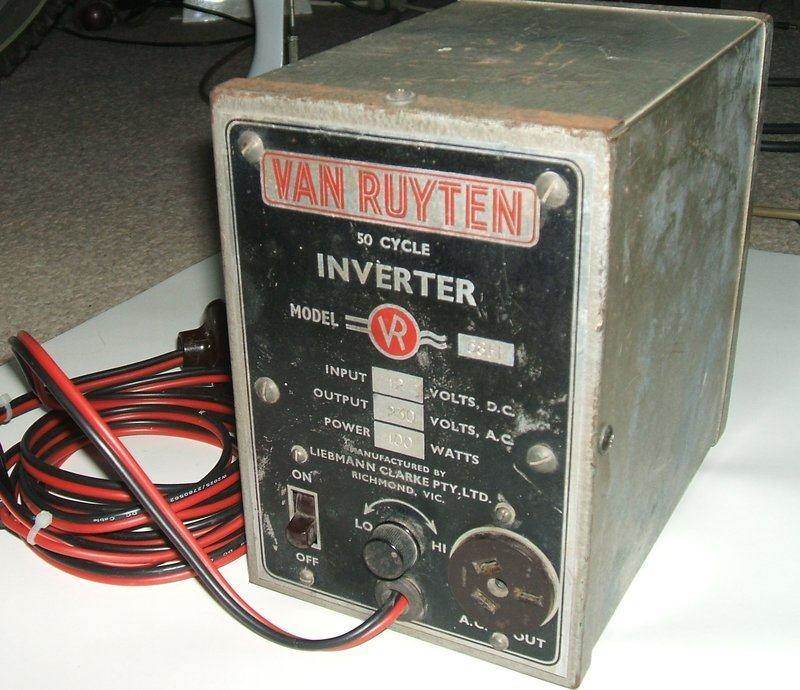

This inverter is another example of the

few Australian made high power 50 cycle types that existed in the pre-solid

state era. The origin of the name Van Ruyten appears to be from a 1930's

trademark of Tilbury & Lewis, a radio manufacturer in Richmond, a suburb

of Melbourne. At some point the name was used by Liebmann Clarke Pty. Ltd,

also of Richmond. Whether or not the premises were the same is not known.

I have seen a more recent vibrator inverter

than this one, of Liebmann Clarke manufacture, but without the Van Ruyten

name. It does appear that as time went on Van Ruyten specialised more in

inverters and less in radio.

Made in Victoria, the output is 230V, not the later Australia wide standard of 240V. For its output power of 100W, this inverter is surprisingly compact. Most of the size and weight is due to the transformer.

I have not been able to put a year on its manufacture, however it does use polyester condensers everywhere except for the timing (buffer) capacitor. The smaller values are the Philips type introduced in the early 1960's, and the larger ones are a PCB mounted type, known as "greencaps". They look like they're late 1960's / early 1970's, and appear to be of Japanese origin. The wiring is all modern PVC. It would certainly appear to be of the last generation of vibrator inverter. There is a "473" on the paper timing capacitor which could mean April 1973.

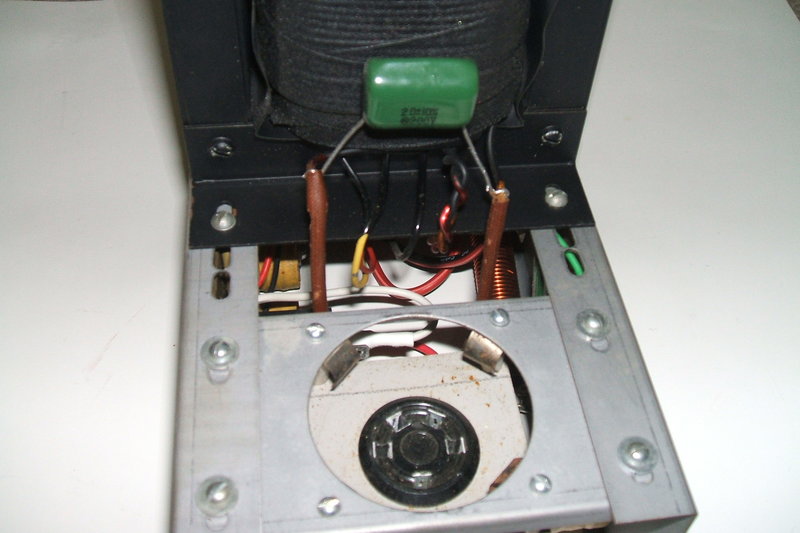

Underneath view with new 3uF timing condenser installed.

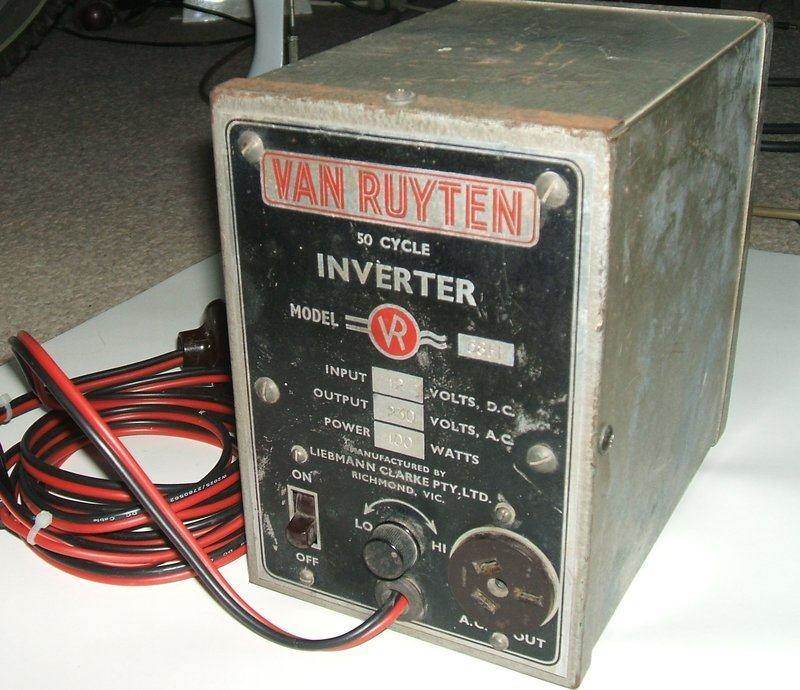

How Much did they Cost?

From the 1961 Radio Parts catalog. The 12V model 58FF described

here cost the equivalent of $700 today!

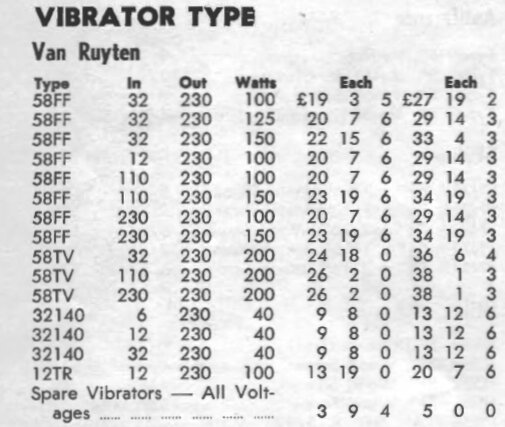

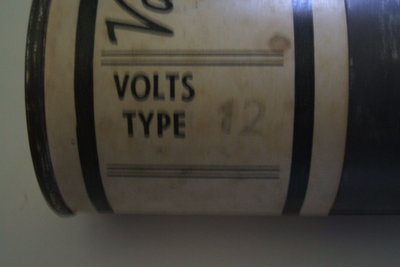

The Vibrator

The vibrator is quite a lot larger than

the typical radio type. It is 120mm tall by 50mm diameter. The origins

are unknown, but as it is 50 cycle and not a modified 60 cycle type, it

could suggest local manufacture. However, it appears to be a copy of an

ATR design.

This vibrator has also been used in Glenradio

inverters. See the Glenradio

100W inverter article for more.

Just because it has a Van Ruyten label,

it does not necessarily mean the company made its own vibrators. There

is also a 32V version of this vibrator.

The vibrator is of the dual interrupter

type, but with the connections between contacts on each side made internally.

It is not therefore possible to use it with current sharing circuits, such

as those using two transformer primaries. The contacts are somewhat larger

than those of a typical radio vibrator in view of the much higher current

rating.

While extra paralleled contacts would

appear to double the current rating of the vibrator, this is in actual

fact not so. It is impossible to ensure each set of contacts open and close

at exactly the same time for any length of time. It is at the closing and

opening of the contacts when they are under the most stress, not when they're

actually closed.

This vibrator uses the series drive method for the driving coil. Apart from the extremely long life provided by doing so, there are two reasons why series drive is preferable for an inverter like this. Firstly, because of the more powerful driving coil, the driving current is higher than a radio vibrator. This means coil resistance is also lower. The effect of this is the unbalance in the transformer primary circuit becomes noticeable. Secondly, shunt drive vibrators can be problematic in starting, depending on loading - which can be quite variable for a general purpose AC inverter.

Vibrator fits a UY-5 socket. The 2uF primary buffer is visible connected

across the primary winding.

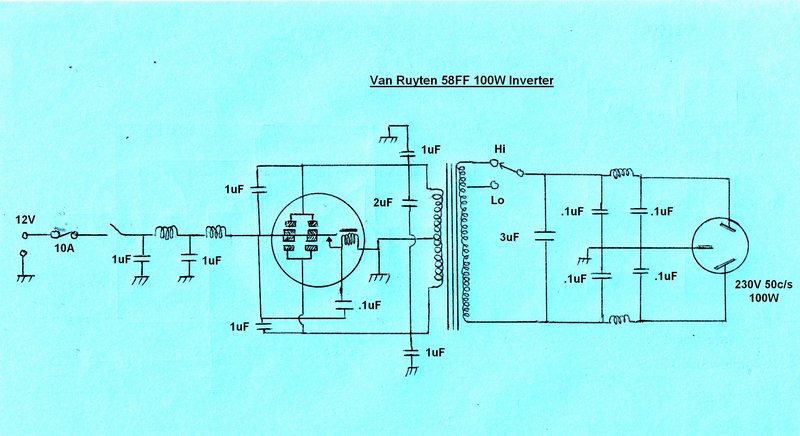

The Circuit

The design is conventional, although with

a slight departure from the usual practice of having the vibrator reed

earthed, and the supply fed to the transformer centre tap. Here, the centre

tap is earthed, and the reed switches the 12V to either side of the primary.

This is the second inverter I have seen that takes this approach, the other

being the Cornell

Dubilier 12A4.

The 12V DC input is filtered for RF by

the usual chokes and condensers. As the condensers are non polarised, input

polarity is not important, except where the inverter is used with an earthed

supply. The inverter case should obviously be connected to the earthed

side of the supply to prevent possible short circuits.

Four 1uF condensers, two from each contact

set to earth, and another two from each contact set to the 12V supply provide

interference suppression. The 2uF across the primary is insufficient to

function completely as a timing condenser, although it would make some

contribution to the overall capacitance required. It would appear to be

more for RF suppression.

The vibrator driving coil has a .1uF across

its contacts, which is essential for spark suppression. A resistor in series

with this condenser would seem to be desirable to limit the capacitor discharge

current when the contacts close. Out of curiosity, I tried running the

vibrator without the condenser and there was a continuous arc across the

contacts. With the .1uF connected, this disappeared completely.

Oak vibrators, although series drive,

do not require an external arc suppression circuit for their driving coils.

This is because of their patented design using an additional short circuited

winding wound with resistance wire, which slows down the rate of magnetic

flux collapse when the contacts open.

Turning now to the secondary circuit, this

is completely conventional, with a high/low switch selecting one of two

tappings on the transformer. Following this is the timing condenser and

a balanced pi filter to reducing RF radiated from the output.

Interestingly, the timing condenser is

connected after the switch, which means the reflected value of buffer capacitance

varies depending on the switch setting. In the "Hi" position there will

be more capacitance than when set to "Lo". However, in practice the value

of buffer capacitance is not as critical as some texts make out - the important

point being that it is never insufficient.

As original to the inverter, the timing capacitance was .56uF. This was found to be completely inadequate as will be described shortly.

Getting it working.

The previous owner had replaced the 12V

supply cable with a length of modern orange four core flex with pairs of

conductors paralleled. The wire gauge looked a bit inadequate for minimal

voltage drop with 10A flowing. Additionally, the original in line fuse

holder had not been retained, thus removing any overload protection.

I used suitable heavy duty figure eight

cable, with a good quality bakelite in line fuse holder with a 10A fuse,

and terminated it with a two pin polarised plug

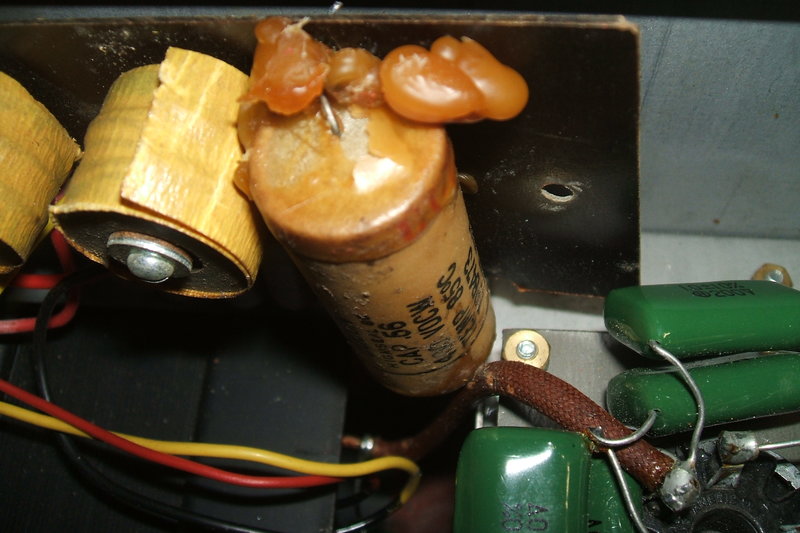

The next point of call was the timing condenser. This was a paper .56uF type, which for an inverter like this, seemed to be a value lower than one would normally use. To cut a long story short, I found that it indeed it was. Not surprisingly, during testing this condenser failed with excessive leakage.

An example of why paper timing condensers need to be replaced.

New Timing Condenser.

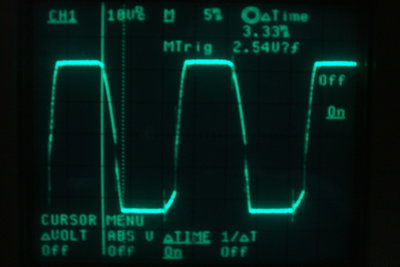

Time to have a look at the waveforms and

see what was going on. The standard procedure is to connect a CRO across

the transformer primary, for this is the waveform the vibrator contacts

see. Because one side of the CRO input is earthed, it means the DC supply

must be floating. (The differential inputs of a dual trace CRO can be used

instead).

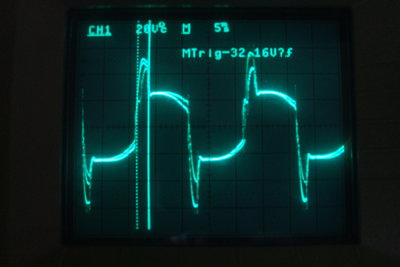

Waveforms with 0.56uF timing capacitor. Left is unloaded; right

is with a 100W incandescent bulb.

As can be seen in the above waveform, there is excessive overshoot. Indeed, there was some arcing at the vibrator contacts. When the inverter was loaded with an incandescent 100W light bulb, the overshoot was eliminated and the arcing stopped, as expected. Clearly, the timing capacitance is inadequate. I can only assume the inverter was mostly run with sufficient load, for the vibrator to have survived this long. Now, to find out what value of timing capacitance would be suitable.

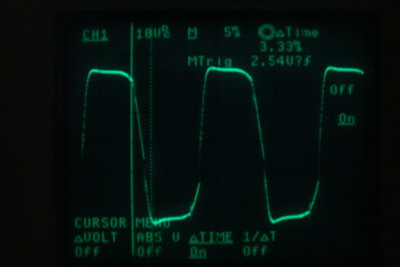

2uF timing condenser, no load.

It didn't take long with a selection of high voltage capacitors to determine that 2uF was the ideal value. No load current consumption on the 12V supply dropped from 4A with the .56uF, to 1.6A with 2uF. As can be seen above, the waveform is much more like it should be. If the inverter was only ever to be used with completely resistive loads, the buffer capacitance could be left at 2uF, but in real world practice it needs to be higher to cater for inductive loads.

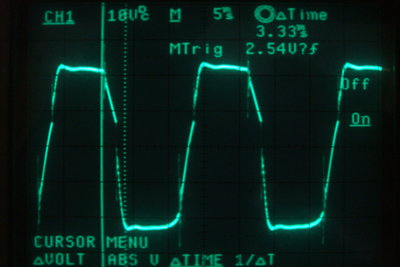

3uF timing condenser, no load at left; with 60W incandescent bulb

load at right.

I used a selection of fluorescent lamps

(20W rapid start [high power factor], double 20W switch start [low power

factor], 15W switch start [low power factor]), and a fan with induction

motor for the tests.

2uF was barely adequate with the L.P.F

loads. In fact, with the 15W lamp, the AC voltage was excessive; around

290V. The optimum capacitance with the 15W lamp was 4uF.

However, the fan and double 20W lamp allowed

a 3uF capacitance with no arcing.

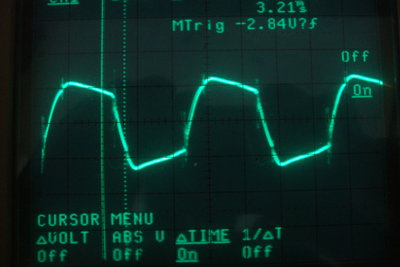

3uF timing with double 20W fluorescent lamp (LPF) at left, and laptop

computer power supply at right.

Grossly excessive timing capacitance is

not desirable, which is why we don't simply install ,say, a 10uF capacitor.

When taken to excess, the current consumption becomes excessive, and the

contacts are liable to arc. Additionally, the capacitor is not correctly

doing its job of reversing the primary voltage at the time when the current

is at a minimum; i.e., when the contacts close and open.

Vibrators used in AC inverters may therefore

be operating under less desirable conditions than those in a DC-DC converter.

Finally, I tested the inverter feeding

a switch mode power supply for a computer. This gave the expected result

of more than optimum timing capacitance being present. Note the steep tilt

as the rising edge commences. The difference with a switchmode power supply

of course is that it draws power only at the voltage peaks of the supply

waveform. The buffer capacitance is not discharged between voltage peaks

as it is when a resistive load is connected.

In summary, for a simple AC inverter like

this, the capacitance must never be below that which is the correct value

for no load. Yet, this value will be found to be insufficient for inductive

loads, such as fluorescent lamps and induction motors. Therefore capacitance

must be added. However, this will then be excess with no load and resistive

loads.

So, a compromise has to be made to increase

the capacitance only by the amount necessary for correct operation with

the inductive loads likely to be used.

In the end, I selected 3uF over 4uF. No

load current consumption is about 2.2A. This is largely swamped out when

the inverter is under load.

Vibrator in action. No arcing visible.

Performance results are as follows. The

12.6V supply was maintained at the plug pins of the supply cable. Of course,

with supply cable resistance, the actual voltage at the transformer primary

will drop under load, and this is reflected in the results.

| Load | Input Current (A)@12.6V | Switch | Output Voltage (Vrms) |

| No load | 2.25 | Low | 270 |

| 2.85 | High | 290 | |

| 60W incandescent | 6.7 | Low | 227 |

| 7.5 | High | 242 | |

| 100W incandescent | 9.3 | Low | 199 |

| >10A | High | 210 | |

| 2x20W fluoro (LPF) | 5.1 | Low | 232 |

| 5.8 | High | 248 | |

| 20W fluoro (HPF) | 4.5 | Low | 232 |

| 4.9 | High | 250 |

The efficiency isn't startling, with 63%

when running the 60W bulb, which is entirely resistive.

The double 20W fluorescent lamp actually

consumes 46W because of ballast losses, and has a power factor of .52.

When powered from this inverter, at 232V, input power at 12.6V is 64W,

meaning an efficiency of 72%.

With the single 20W fluorescent lamp,

this already contains a phase correction capacitor, so has high power factor,

and thus appears largely resistive as a load. It draws 32W with a PF of

.8 at 235V. Input power with the inverter at 12.6V is 57W. Efficiency is

then 56%. Despite this, it would be much better to run this lamp than the

60W bulb because of the fluorescent tube being a more efficient light source.

We can see the effect of the value of

the timing condenser favouring the low power factor inductive load.