This surviving Audiffren machine was used as a teaching aid at a technical college until recently. See the patents for further details http://www.google.com/patents/US551107

Please visit the Monitor Top Refrigerator Forum here http://monitortop.freeforums.net/

Restoration of a General Electric CA Monitor Top Refrigerator - Part 1.

1.1 Background to the Monitor Top

The first hermetic refrigeration unit was the Audiffren machine. It

had been invented by a French monk, Marcel Audiffren, and used SO2 as refrigerant.

General Electric built these machines until the early 1920's but they were

not really suited to domestic use because of the size of the cooling unit,

and that it had to be remotely installed from the cabinet.

This surviving Audiffren machine was used as a teaching aid at a

technical college until recently. See the patents for further details http://www.google.com/patents/US551107

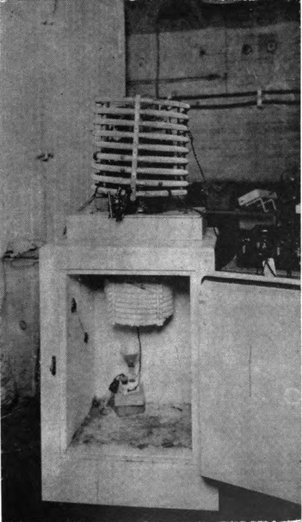

Using the principles of the Audiffren machine, Clark Orr developed the

OC-2, intially with a water cooled condenser, then an air cooled version.

The cooling unit was self contained and sat in the top of a conventional

ice box.

Details of the OC-2. This model was used to test the feasibility

of General Electric entering into the field of domestic refrigeration.

As can be seen, the "Monitor Top" concept was already in place.

By this time, GE had decided to make a serious entry into the domestic

refrigeration market, partly as a way for customers to consume more

electric power, thus increasing GE's power station profits, but also to

provide greater recognition for the company, as it would be able to supply

all domestic appliances, instead of just some.

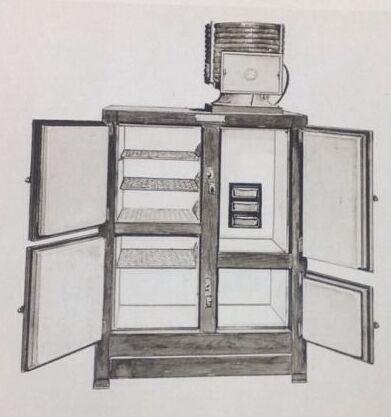

By 1925, Clark Orr’s OC-2 had been redesigned into something more reliable

and suited for mass production. The final design, the DR (Domestic Refrigerator),

was released for sale in 1927.

Prototype Monitor Top (1925)

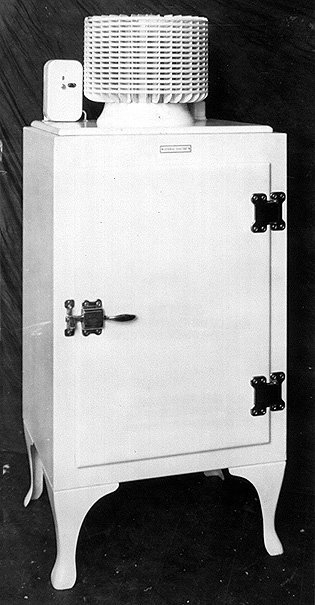

• The DR series from 1927 to 1932 is characterised by open copper tubing

for the condenser, and uses Sulphur Dioxide (S02) for refrigerant.

DR (Domestic Refrigerator) series 1927-1932.

• In 1933, GE released the CA series. In the late 1920's, experiments

had found methyl formate to be an efficient refrigerant with the advantage

of being much safer and easier to handle than SO2. GE patented methyl formate

as a refrigerant, and it was used in the new model. The CA was also

the first model with a flat plate condenser.

1933 CA (form A type)

1934 CA (form B type)

• In mid 1934, the first CK models appeared. Resembling the later CA,

it had reverted back to SO2 refrigerant; this being because methyl formate

was found to be unstable, requiring some refrigerators to be purged of

non condensable gases from time to time. The late 1930’s saw the availability

of Freon (R12) developed by Thomas Midgley of Frigidaire (General Motors),

and this eliminated SO2 for domestic refrigeration. The last rebuilt

CK-3’s were filled with R12. By 1937, fashion changes saw the end

of the Monitor Top styling, although the design lived on until 1942 in

the form of the Flatop.

1935 CK. Note the similar appearance to the 1934 CA.

• The CG (Globe Top) of 1935 was an economy model based on the CK, and

did not include a user adjustable temperature or defrost control. It also

used SO2.

CG Globe Top (1935-1936)

• The CF (Flatop) and related models CE,CH,CJ and FBA were the result

of fashion changes. These models were in production from 1935 to 1942,

and are not to be confused with earlier non hermetic designs of similar

appearance. They were the last of the Monitor Top generation. A few later

models were factory filled with Freon 12, but most used SO2. The Flatop

is essentially a CK with the parts rearranged so that the compressor is

under the cabinet. The condenser is either on the back or underneath, some

being fan forced.

Flatop from 1939. Many different cabinet styles were used, but still

remained essentially a CK inside.

Cabinet dimensions were standardised throughout production so that tops

of different years are interchangeable. In fact, failure of a cooling unit

would often result in the current production being used for replacement.

At one time, advertising claimed that one in every three refrigerators

was a Monitor Top, and because of the impressive reliability of the “sealed

in steel” mechanism, many operational units have survived into the 21st

century.

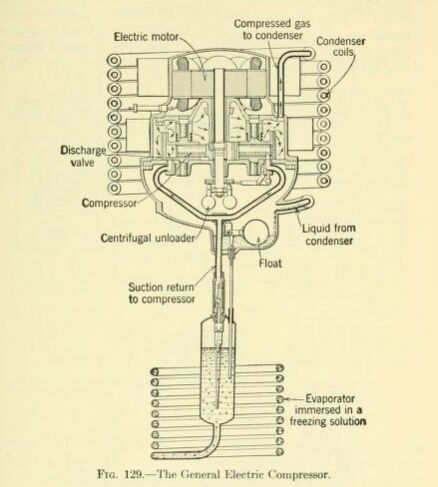

Despite their unusual appearance, and use of what are now considered

unusual refrigerants, Monitor Tops follow the text book principles of refrigeration.

An evaporator, condenser, compressor, receiver, and metering device are

all used and are conventional. However, the metering device, being a high

side float valve, is now obsolete in domestic refrigerators; its place

being taken by a capillary tube.

It is surprising that despite all the advantages of the hermetic design,

GE also produced non hermetic refrigerators. It can only be assumed the

lower cost was behind this.

Post war, there was little left of Monitor Top design in GE's refrigerators.

Apart from a new compressor design, R12 was now standard as were capillary

tube metering devices. The detachable top was also gone, except for the

FEA replacement units.

In Australia, the Monitor Tops were imported by Australian General Electric and sold extensively in the eastern states. As part of California had a 50 cycle mains supply, units were already being produced for this frequency, and merely required the addition of a locally produced 110V step down transformer to enable use on the 210-250V Australian mains supply. This transformer was bolted to the underside of the cabinet. Unlike the United States, very few Monitor Tops have survived in Australia. Proportionally fewer were sold here per head of population. One reason being that outside of the cities and towns, electric supply mains were not common at the time, and where they did exist, the supply was often DC.

1.2 Background to the CA Monitor Top.

The first CA’s were produced in 1933, this being the “form A” version.

It is characterised by a tall flat plate condenser with evenly spaced embossed

tubing, and the controls on the cabinet top immediately beneath. A float

chamber protrudes from the back corner of the cabinet.

In 1934 the “form B” version was produced. It has a wider diameter

condenser, with the controls mounted in the middle between the embossed

tubing. The float valve chamber is mostly underneath the condenser fins,

but has an extension tube which rises to the condenser top. This was done

to increase the area where non condensable gases could collect, and thus

require less frequent purging than the “form A” model. A further modification

was incorporated in the "form B" model to further delay the purging procedure.

This was a very fine diameter tube to allow the non condensable gases to

bypass the float valve and collect in the compressor dome.

Two sizes of cooling unit were produced; CA-1 and CA-2. 50 and 60 cycle

models were produced; this being indicated in the “5” or “6” model number

suffix.

Unlike the previous DR, and later models, the CA’s use Methyl Formate

(R611) for refrigerant. As SO2 (R764) is an obnoxious refrigerant should

it leak or come into contact with moisture, GE sought alternatives. Methyl

Formate was chosen because of its lower toxicity, and largely absent odour.

GE patented its use as a refrigerant and was the only known manufacture

to use it.

Methyl Formate is a low pressure refrigerant, and thus the CA models

use a form of rotary compressor. The S02 models use a reciprocating piston

type.

By low pressure, the refrigerant is below or around atmospheric pressure,

even on the high side. The difference between high and low side pressures

is also not as extreme.

It was discovered that non condensable gases could be problematic with

Methyl Formate. They would collect in the float chamber, forcing the float

down, and thus shutting off refrigerant flow. This would require a purging

procedure to bleed them off. The non condensables come largely from the

decomposition of the Methyl Formate itself, and also moisture or air that

might be in the system. One disadvantage of low pressure refrigeration

systems is that air is sucked into the system if there is a leak. It is

not possible to locate leaks in this situation. Positive pressure systems

will continue to work until an excessive amount of refrigerant is lost,

and locating leaks is straightforward.

The fact that not all refrigerators were affected by non condensable

gases is supported by the many extant units still running without being

purged. However, the less than perfect record must have caused GE to return

to S02. Thus, the CK was born. It is essentially a CA that has been modified

to run SO2. The compressor was changed to a high pressure Scotch

Yoke piston type, and S02 refrigerant used. The condenser, controls, and

cabinet were essentially those from the CA form B. Because of the higher

pressure that S02 works at, R12 was compatible with the design when it

became available, and merely required a small modification to the compressor

piston to provide a shorter stroke. Some CF models and rebuilt CK30's were

factory built to use R12. Post war, GE was no longer using SO2.