The Electronically Cranked Coil Tester

Model T owners have often come up against

the difficulty of correctly testing and adjusting their ignition coils.

A fortunate few own a hand cranked tester of the kind illustrated in the

Model T Ford Service Manual. Others try and get by with simple buzz box

testers. There are even some who use completely non electronic methods,

such as measuring spring tension, or listening for a certain "musical note"

as the coils buzz. To any technically competent person, these latter two

methods are extremely crude, and they cannot give known or repeatable results.

Hand cranked coil testers (HCCT) are few

and far between, and when they do turn up are extremely expensive - hence

the crude methods used instead. However, there is still a limitation with

the HCCT, in that there is no way of setting the coil's firing time so

it is the same as all the others.

Electronic Coil Testing.

At this point I recommend reading the

article

here if you have not already done so. It goes into further detail on

why setting coils for equal firing time is important, and describes an

electronic tester that performs this function. While the tester so described

works very well, it requires an oscilloscope, and the ability to interpret

its display. Thus, it is only suitable for the Model T owner with an electronics

background.

The good news is there is now a test instrument

that anyone can use, the ECCT. It works on the same principles as my CRO

based tester, but it has been carefully designed so that any Model T owner

can use it. I have no affiliation with the design or manufacture of this

instrument, but I have had the opportunity to try one out.

It immediately became very clear that

the ECCT fulfills the need for an instrument that anyone can use, regardless

of technical ability. It is not only very inexpensive compared to a HCCT

(if you can get one!), but allows for the coils to be set for the all important

equal firing time. Additionally, facilities to test the coil capacitor

are provided, and for those with a working magneto, the instrument can

test this also.

What is the ECCT?

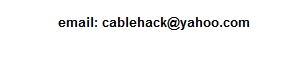

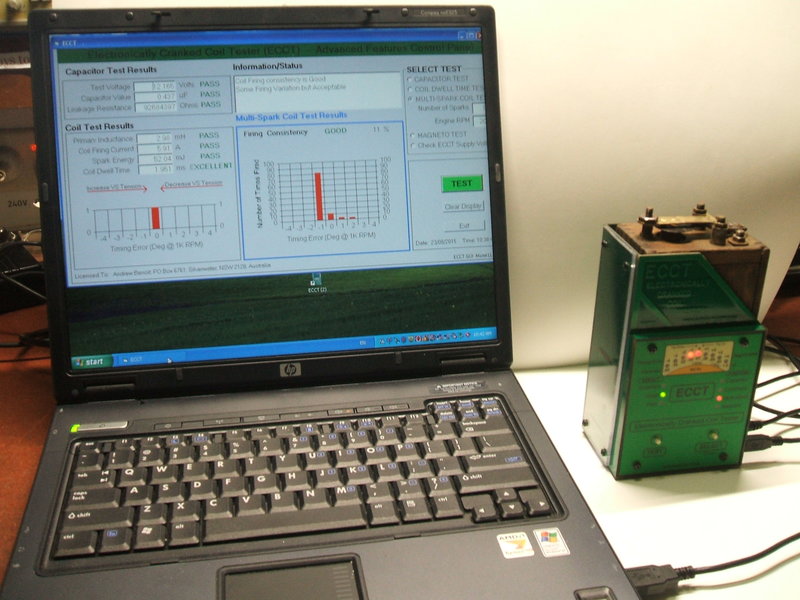

The "Electronically Cranked Coil Tester"

is a very compact unit, hardly bigger than the coil itself. The unit is

made using printed circuit boards for its enclosure and has a very simple,

yet elegant look. It runs from an external 12V 8A switchmode power supply,

which has the usual 100-240VAC input via an IEC socket. Thus, it is a simple

matter to substitute a local power cable wherever you might be in the world.

Provided care is taken with polarity, it can also be used with a 12V battery,

giving complete portability.

On the front panel is a LED display and

testing switches.

The coil to be tested is simply inserted

and then the relevant buttons pressed to perform the required test.

In its basic form, the instrument will

perform coil and capacitor tests, with the LED's displaying the results.

The "Excellent", "Good", and "Poor" indicators mean that no technical interpretation

is required. When setting the vibrator spring tension, one simply observes

the timing error LED's and reduces or increases the tension for a zero

degree timing error.

It really is that easy to use. However,

don't be deceived by the simplicity, because internally, it is a very accurate

instrument. It is this simplicity plus accuracy aspect that makes it the

perfect coil tester for everyone.

Computer Interface.

Of course, Model T owners who have a technical

understanding of the ignition system will be keen to see more than a LED

display. In view of this, a USB port is provided for interface to a computer.

This opens up a whole new world because results are now displayed graphically,

and numerically.

It must be pointed out that the computer

interface is an option, and for the non technical user who wants to keep

the cost down, it is not actually required. The simple front panel LED

display will allow coils to be adjusted just as effectively.

Trying out the ECCT.

The earliest computer I have with USB

support has Windows 2000. The ECCT software functioned perfectly on this,

as well as other machines with XP and Windows 7. What I did find was that

a minimum screen resolution of 1280 x 1024 is needed, otherwise the right

hand side of the software window is cropped. This does not impede functionality,

however. I found the ECCT to be intuitive right from the start, probably

because of my experience with this method of coil adjustment. Nevertheless,

the supplied instructions are very well written in a step by step format.

Directions are given on how to correct the coil settings if they are not

as they should be. Now, let's look at the tests the ECCT can perform:

Capacitance.

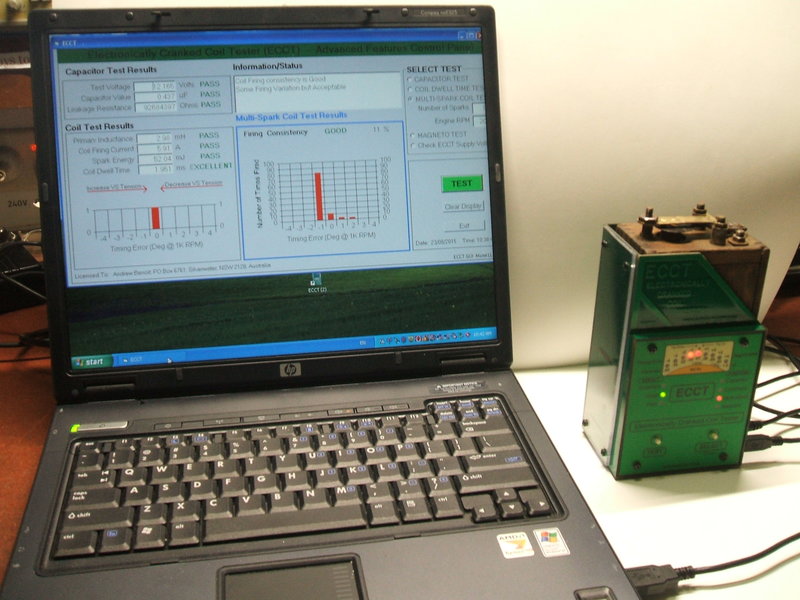

This is the first test that should be performed,

because if the capacitor is excessively leaky, firing performance may be

reduced regardless of how well the points are set. Capacitors can also

fail short circuit or open circuit, and no amount of point adjustment will

give a proper spark.

Here, the capacitor measures over 92M

which is an extremely low leakage. This is to be expected if there is a

new capacitor installed. Old leaky paper capacitors may indicate 100K ohms

or less. The test fails with under 10M leakage. That is not to infer a

coil with, say 2M leakage, is defective and won't perform adequately, but

it indicates something is not as good as it could be. Typically, this would

be because the original capacitor is still in place, and/or the coil box

wood has been painted with something conductive. My recommendation is to

routinely replace original coil capacitors, because it eliminates future

problems, ensuring the spark is always as strong as it can be. Modern plastic

capacitors do not deteriorate, so once installed they will last a lifetime.

Of course, the correct capacitors must be used or short life will result.

See here for

further details.

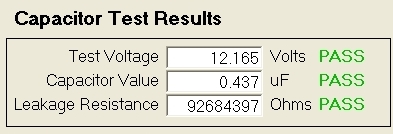

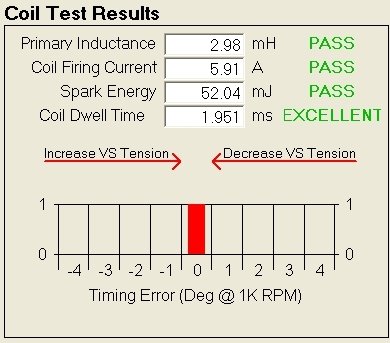

Coil & Dwell.

Having ensured the capacitor is satisfactory,

the next test to perform is the coil firing time (dwell). What is dwell

you might ask? In an inductive circuit, such as a Ford coil (or even a

modern ignition coil), when current is applied it takes a certain amount

of time for the iron core to fully build up its magnetic field. When fully

built up, it is "saturated" and continuing to apply current has no further

effect. Most efficient coil performance will occur when the coil fires

just as the saturation point is reached. Here, the magnetic field is strongest

without wasting power. Any further application of current is simply wasted

as heat. With a Ford coil, the ideal dwell time happens to be 3.5ms if

the supply is 6V, and 2ms if it is 12V. With magneto operation, the dwell

time varies with the change in voltage. The important thing is that each

coil has the same dwell time to ensure that no cylinder fires advanced

or retarded relative to the others. This is the basis of ECCT testing.

As can be seen, the primary coil inductance

is measured, as is the peak firing current. This is the current right at

the firing time, and is not to be confused with the lower, average, current

often quoted for coil adjustment (1.3A at 6V). From this, the ECCT microprocessor

calculates the actual spark energy.

The all important coil dwell time is measured

to an accuracy of three decimal places. While such accuracy is not actually

necessary, it does show the instrument can actually measure it. With the

coil test voltage performed at 12V, the ideal firing time has been determined

to be 2ms, so this corresponds to a zero degree timing error.

This corresponds to 3.5ms on my own CRO

based tester, when the test is performed at 6V. While it is perfectly satisfactory

to set firing time at 6V, it is really necessary to use 12V to check for

multiple sparking, as this does not always show up on the lower voltage.

My own tester can do this, and the ECCT does so by default.

While the dwell test is being performed,

any signs of multiple sparking are detected. This results in a message

to adjust the upper cushion spring tension.

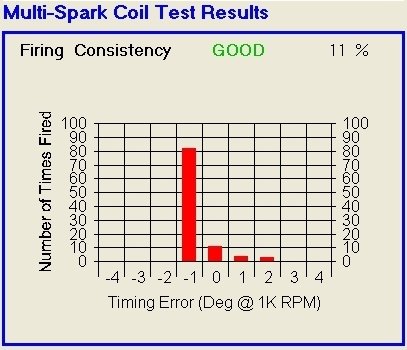

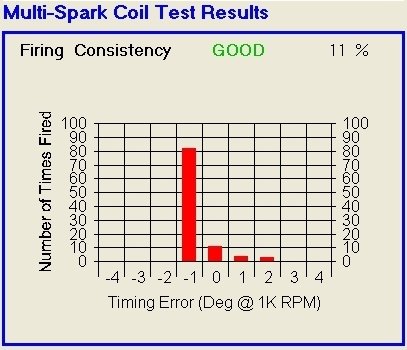

Multi-Spark test.

In this test, the coil is fired at up

to 100 times with and equivalent engine speed of up to 2000rpm. These parameters

are user selectable.

The purpose is to examine the firing consistency.

While one single fire may appear to show a good result, is this always

consistent? Any deficiency with the coil points will show up when rapidly

fired, like they would be in a car at normal engine speeds. Problems like

contact bounce and dirty contacts will show up here.

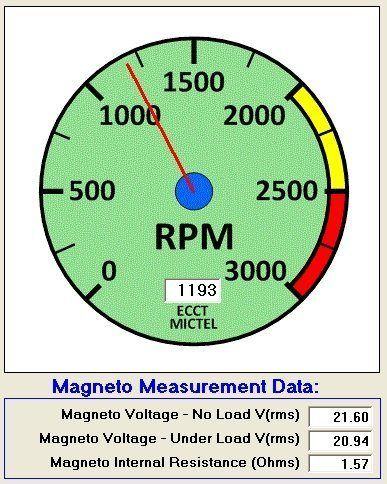

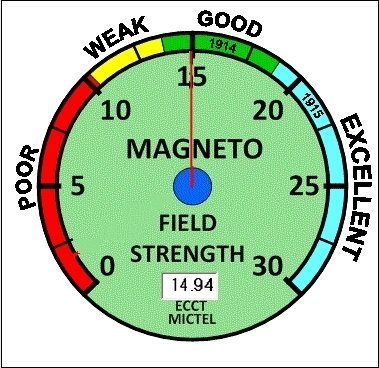

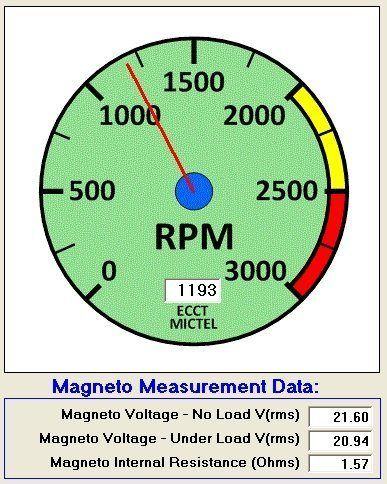

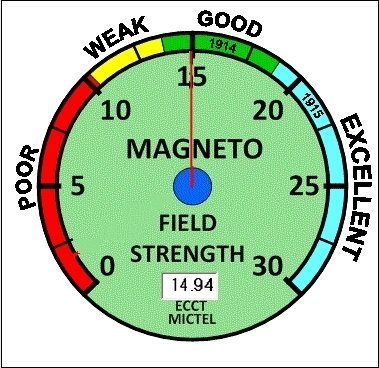

Magneto test.

This is an additional option. Given that

not all Model T's have a working magneto, further cost saving is possible

by not opting in for this feature.

Magneto voltage is measured along with

engine rpm.

Load testing is performed by a simulated

St. Louis Magneto Tester, an original design from the T era, renowned for

its ability to test a magneto’s power output regardless of engine speed.

Testing The ECCT.

With all features enabled in the ECCT

I was testing, it was an ideal opportunity to do some detailed tests and

compare with my own electronic tester. As my tester had been developed

completely independently, it was fascinating to see how it compared, and

to confirm the legitimacy of the testing method.

Capacitance tests.

As expected, capacitor values tested within

tolerance, when compared to measurements taken from an Escort ELC-131D

hand held LCR meter. It was noted that accuracy decreased with an increase

of capacitor leakage. However, this in itself was not a limitation because

capacitors with high leakage should be replaced anyway.

One thing that did cause confusion was

that the capacitor test would fail, with a reading of 0uF with some original

paper capacitors. This was found to be because of a small voltage being

generated from within the capacitor, most likely due to electrolytic action

occurring because of moisture. I measured up to 320mV into a 10M DVM with

the set of original coils I used for the test. Again, such readings indicate

the capacitor should be replaced.

It was found also that incorrect results

would be given when the coil points mounting nuts were touched during the

test. Evidently, there was enough 50c/s radiation from the power mains

being picked up (1.2V p-p into 1M) to upset the testing. This was confirmed

when the ECCT was operated from a battery away from the power mains. Here

it worked normally even if the nuts were touched. The capacitance

test calls for holding down the vibrator spring so that the capacitor is

not being short circuited. However, if the vibrator spring touches the

coil core underneath, then leakage to this point is measured as well, giving

a not entirely true capacitance leakage result.

Ultimately, the most accurate way to measure

the capacitor is by inserting a piece of plastic between the contact points

and not touching any part of the coil during the test.

Coil firing time.

This test actually showed up some inaccuracies

with my own tester. While the results were sometimes identical, at other

times they were not. It became clear that using a low cost CRO was one

limitation. For one thing, the timebase calibration was found to have drifted,

and was not completely linear. There was also the possibility of Parallax

error because of the graticule's distance from the phosphor screen of the

CRT. These problems have since been eliminated since I performed the tests

by changing to a decent CRO; a Tektronix TAS475.

Once that was cleared up, the ECCT was

found to be completely accurate with regards to the coil firing time. It

also was found to reliably detect multiple sparking. If it showed up on

the CRO, then the ECCT also detected it, and vice versa. From this test

alone, it is clear that the ECCT can substitute for mechanical testers

such as the HCCT.

As was expected, it was found that firing

current varies slightly amongst individual coils, even though the firing

time is identical. This is a trap for those who have always set by current

on other kinds of tester. The golden rule is to set for equal firing time,

not

equal current.

Coil Firing Consistency.

My CRO based tester does not have the

ability to log firing consistency, but one can subjectively get an idea

of how good or bad this is by listening to and observing the coil sparking.

The ECCT can log this over a period of up to 100 sparks. I found with coils

which had a less than perfect firing consistency, on the CRO based tester,

that the ECCT would detect this also, and vice versa.

Magneto Tests.

This was something I could not test in

a real world situation because I do not have a magneto in my Model T. However,

using a BWD Mini Lab 604 function generator, I was able to determine that

the tachometer and magneto voltmeter were accurate. The latter is actually

a true rms voltmeter, and gave consistent readings regardless of input

waveform. I used sine, triangle, and square wave inputs for the test.

The tachometer readings were calculated

from the input frequency, and again were found to be accurate.

A challenge was simulating the magneto

field strength test. I largely overcame this by using an audio power amplifier

in between the function generator and the ECCT.

This was necessary to get the low output

impedance and voltage swing to simulate a real magneto. It was found that

the pass/fail for the internal resistance test was 3 ohms. A high resistance

reading alerts the user to a fault such as a magneto post with poor contact.

While I couldn't actually do the field

strength test and compare the reading against anything, it certainly appeared

to function as it should.

Overall Impressions of the ECCT.

As the designer of the CRO based tester,

I related to the ECCT straight away, and understood the results with no

further interpretation required. This is because the coil testing feature

of the ECCT works on the same principle of measuring dwell.

A welcome option would be to include a

dwell time (ms) calibration for the graphical and LED display. However,

it is understood the ECCT is designed for a market more familiar with mechanical

engineering, hence the preference for displaying degrees. This is a very

minor point, because anyone who wants a millisecond reading would most

likely be using the software, which does display this.

Using the ECCT showed it was much more

than just a coil tester. It is in fact a comprehensive Model T ignition

system analyser, suitable for coils used either on battery or magneto.

It is hard to imagine a more compact,

attractive, and user friendly design with the simple, yet effective and

rugged method of construction used.

I found the instructions to be well written,

in logical order, and in terminology anyone can understand. How to interpret

the results and take corrective action is made particularly clear.

Versatility is also a welcome part of

the ECCT which should appeal to prospective purchasers. The user is not

obliged to purchase the software interface, if this is seen as too technical.

The essential results are visible on the basic tester, and are just as

accurate. Likewise, those without magnetos do not need to purchase the

magneto testing option.

Naturally, all the extra features which

the ECCT has are interesting in themselves. If you have an interest in

the Model T ignition system you will find it addictive, wanting to spend

hours with the ECCT learning all about coil adjustments and characteristics.

In fact, I was so impressed with the ECCT

that I bought one!

In terms of my own personal use, I use

the ECCT in conjunction with my CRO based tester. The CRO based tester

is good for the initial coil test because it allows quick real time adjustment.

Then the ECCT is used for the final firing time accuracy, and to look at

the other coil characteristics. To provide a CRO interface on the ECCT

can be done during manufacture, but it would be lost on most users. However,

once I did purchase my own ECCT, I did fit it with connections to trigger

a CRO, and provide a current waveform. Now, I have the perfect coil tester

- a visual current waveform of the coil firing and the superior

accuracy that the ECCT offers.

Why the Model T owner will benefit

from the ECCT.

It should be clear by now that there is

a lot more to the Model T ignition system than simply making the coils

produce a spark. A car with an ignition system set up that way will actually

run, but the full potential of its performance will be impossible to achieve.

These are the cars that struggle to get up to 60km/h and run rough.

Improperly set coils may suffer from:

-

Insufficient current leading to a weak spark,

especially with 6V or with low engine revs on magneto.

-

Too much current leading to overheating coils

and burned points.

-

Uneven dwell time, leading to cylinders firing

retarded or advanced relative to the others in the set.

-

Multiple sparking which causes a loss of sparking

power on the initial fire, and being voltage dependent, causes rough running

on magneto.

Buzz box testers can test for the first two

characteristics only. While in theory, their meter could show the dwell

time, this would only happen if the meter: 1) had sufficient accuracy,

and 2) all coils had identical characteristics. The reality is there is

a variation between individual coils and dwell time vs. current.

The HCCT is a vast improvement in that

it can test for multiple sparking as well as coil current. Again, because

of the simple analog meter and differing coil characteristics, it still

cannot test dwell time.

For this reason, the Model T owner who

wants optimum ignition performance will benefit from the ECCT. It performs

all these tests.

Clearly, electronic testing, such as that

provided by the ECCT, is the future of Model T Ford coil testing. All aspects

of coil operation, invisible on other testers, can now be displayed, and

corrected where necessary.

The ECCT

site is here. More information is available there on how the ECCT was

developed, and you can also get a feel for the instrument by downloading

the instructions.

I really do urge all Model T owners using

the original ignition system to think about this, because properly adjusted

coils and a good timer will give performance as good as a distributor system.

Home