Here resides the Edwards DES125 stainless steel water heater.

Having set up the solar powered electrical system for my house and seen how successful it was, the next step for less dependence on outside services controlled by big business, was to have my water heated by solar.

Learning about water heaters.

Late 1996, when my 15 gallon Zip water

heater tank had corroded to the point of brazing up the pinholes being

a futile exercise, I was forced to replace it. This is when I learned that

most water heaters for sale now are essentially junk. My original tank

was made of cusilman bronze and it had lasted 30 odd years with full mains

pressure applied to it. I'd also lived with copper and copper lined tanks

which were also reliable. Much to my surprise neither cusilman bronze,

or my other choice, copper lined steel (eg. Rheem Coppermatic) heaters

were still being made. Something about water quality the manufacturers

told me...but they could offer me any number of models with glass lined

tanks. No way would I spend money on something which was actually destined

to fail from the first day it held water. For those unfamiliar with the

concept, glass lined tanks are a mild steel (just saying that makes one

think of rust) with vitreous enamel (fancy name for molten glass) sprayed

onto the inside surface, supposedly protecting it from corrosion. Which

it would, except that the steel cylinder expands and contracts as it heats

and cools. As glass is not flexible, minute cracks appear and the tank

is now doomed. To slow down the rate of corrosion, a sacrificial anode

is inserted into the tank. It's made of magnesium and is meant to corrode

instead of the steel. However, most owners of glass lined tanks never check

the anodes, or replace them once corroded away. Also, the corroding magnesium

ends up in the tank and hence the hot water that issues forth. Such tanks

often have words like "Vitreous", "Enamel", "Glass" or that abominable

misspelling by Rheem, "Glas", in their model names. The inside of them,

if you haven't ever seen a cutaway model, is just like an oven baking dish.

If you're unfortunate enough to be stuck with this kind of heater, run

it at the lowest temperature and water supply pressure you can, and check

the sacrificial anode. Edwards and Beasley seem to be the predominate manufacturers

of stainless steel water heaters, so in the meantime it's worth familiarising

yourself with their models, ready for when the time comes.

Most water heaters in Australia are of

the mains pressure type, hence the requirement for a strong tank. To allow

for pressure build up, a TPR (Temperature and Pressure Relief) valve is

fitted. This opens thermostatically at 99 degrees (in case the heating

element doesn't shut off) so that steam doesn't build up causing an explosion.

In addition, should the thermal part of the valve be not functioning, the

valve will open with extreme pressure alone (chosen to be above the pressure

of the water supply).

Once popular until the 1960's when the

Rheem Coppermatics came into vogue, were gravity fed copper tanks, usually

installed inside the roof space. These have an exceptionally good life,

and fed from an open cistern, do not require all the pressure release paraphernalia

of mains pressure heaters.

As I didn't have the roof space to accommodate

such a heater, I stayed with the mains pressure option.

The Edwards Stainless

Steel Water Heater.

Further into my enquiries, I soon discovered

the stainless steel water heater. Problem solved. It does surprise me that

so few water heaters sold are of the stainless steel variety. Perhaps the

extra cost puts people off and they think five or ten years life is satisfactory.

The model I chose was an Edwards Energy

Systems DES125 which is a 125 litre mains pressure model. It is made from

316 stainless steel and had a ten year warranty. I installed the lowest

pressure reducing valve I could get (350kpa) to further increase the life.

Interestingly, the Edwards water heaters come with a cold water expansion

valve. This is a reflection of their Western Australian origins. In that

State and also South Australia, this is apparently a compulsory requirement.

In those areas the water supplies are prone to cause scale build up on

the TPR valves. This can cause them not to reseat properly after being

activated, and thus the familiar failure with constantly dripping hot water.

The ingenious way out of this is to have an expansion valve on the cold

water inlet of the tank. Because the cold water does not cause scale build

up, the valve is reliable. The cold water expansion valve therefore has

a lower pressure limit than the TPR valve, so in effect the TPR valve is

only activated if the water approaches boiling point. The additional advantage

of this scheme is that only cold water is lost during the heating of the

tank, not hot water as is the case when there's only a TPR valve. Thus

the heating energy is lessened. Unfortunately, in recent years, Edwards

was taken over by Rheem. This has lead the existence of "Edwards" labels

on some glass lined tanks.

Here resides the Edwards DES125 stainless steel water

heater.

Solahart.

I did some research into solar water heaters

around 1989 when I'd wanted to install one at our weekend house. At the

time I was keen on the 180 litre Solahart. They had developed this "black

chrome miracle" collector panel which supposedly transferred more of the

sun's heat to the water. They also had developed a novel heat exchange

system for use in frost prone areas. In such locations, the panels can

be damaged overnight in sub zero temperatures. The water in the panels

freezes, expands, and thus ruptures the pipes in the collector. Ways to

solve this problem are to use frost valves which open in the cold, allowing

hot water from the tank to flow through the panel. Apparently such valves

are unreliable as well as wasting hot water. Another method is to circulate

a small amount of water through the panels by means of a pump. While there

is no cold water loss, some of the heater water stored in the tank is wasted

warming the panels. The Solahart approach was to heat the tank by means

of antifreeze fluid which was in turn heated by the solar panels. This

neatly solves the problem with no heat or water wastage. However, the heating

efficiency is less due to losses in the heat exchange process, and given

their tanks are glass lined, I would think the glass would function as

an insulating layer.

When it came to replacing my water heater

I could have used the Edwards version with stainless steel tank, but at

that time cost really was an issue so I took the easy way out and stayed

electric only. Electricty charges in 1996 were also less than half at the

present time (2013), so running cost was not an issue.

Evacuated Tube Collectors.

Towards the end of 2007 I'd become curious

again about solar water heating. I'd now had the solar electric supply

operating for two years, as well as the wind generator. A large proportion

of the house water supply was coming from a 1000 gallon rain water tank,

so solar water heating was next on the agenda.

The people I'd spoken to at Edwards 11

years ago told me my tank could be converted to solar and this had always

stuck in my mind...so onto the internet to see what I could find. My initial

idea was just to get a conventional flat collector panel and connect to

my existing tank. I quickly discovered that there was a new kind of collector

with many advantages. It was called the Evacuated Tube Collector. Not only

was it very light in weight, but very easy to install and frost protection

was not an issue. In my area, frost protection would be necessary with

a conventional system. The thought of antifreeze fluid leaking and running

down the roof into my tank was also another reason to avoid the well known

commercially made systems.

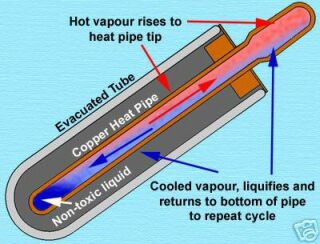

The collector consists of an array of

glass tubes. Inside the glass tubes are copper tubes filled with liquid.

These copper tubes are heated by the sun (they have black fins attached),

and the hot liquid rises to the top of the tube which is in contact with

a heat exchanger. Through this heat exchanger flows the water to be heated.

The key to this working so well is that the glass tubes are constructed

like a thermos flask. There is a vacuum between the inner and outer tube

which means that heat trapped inside cannot easily get out. Also being

round, it means the angle of the sun is not critical and the tubes receive

radiation over a much greater period of the day than would a flat panel.

As there is no water flowing through the actual collectors, they are immune

to frost damage. The whole array weighs only about 60 kg, with the weight

being only that of the glass tubes, heat exchanger manifold, and stand.

Retrofitting to an existing

tank.

A typical vertical water heater tank has

a cold water inlet right at the bottom and the hot water outlet right at

the top. A third connection at the top is for the TPR valve, but some heaters

combine this with the hot outlet. The heating element is located in the

lower quarter of the tank and thus heats the water above it. A tank made

for solar use has an extra connection about halfway up. This is where the

warm water from the solar panel is fed into the tank. The cold water for

the panel comes from the bottom of the tank. Thus when the panel is heated,

thermosiphon occurs. How to use an existing tank? The cold supply for the

panel is easy as there's already a connection at the bottom of the tank;

i.e. the cold water supply inlet. The hot output from the panel is the

tricky part. If it was merely fed into the top connection of the tank,

there could be conflict with the hot water return from the solar collector;

eg. if the water from the collector is cooler it will mix with the hot

water from the tank and thus reduce the outgoing water temperature. I eventually

discovered the trick is to use something called a "five way valve", or

"solar conversion valve".

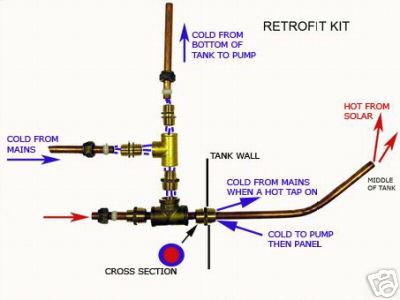

This diagram came from the eBay seller of my kit and

illustrates the five way valve.

What happens is that the cold water connection at the bottom of the tank performs two functions. The cold water is fed into here as well as to the solar panel. However, the hot water is also fed via this connection to a length of tubing inserted into the tank, the end of which is away from the cold inlet. So, cold water is drawn from the bottom of the tank, pumped through the solar collector, heated, and then injected into the bottom of the tank (away from the cold area) and rises to the top. Thus, no modifications to the tank are required. Obviously, the tube injecting the hot water must be of smaller diameter than the cold water inlet. Typically, the cold water inlet is 3/4" which allows a 1/2" injection tube. The remaining 1/4" gap is quite sufficient for cold water flow.

Five way valve made from ordinary plumbing fittings.

The length of copper tube protruding into the tank is somewhat longer in

my installation.

This type of conversion applies to a ground

standing tank with solar panels on the roof. Unfortunately, for thermosiphon

to occur, the tank needs to be above the collectors as hot water naturally

rises. With this type of installation a circulating pump is therefore required,

so unless this is powered from a photo voltaic panel the hot water is not

entirely free. However, the pump is only for circulation instead of having

to push a head of water so power requirements aren't that huge. My Wilo

pump supposedly draws 46W. Somewhat cheaper to run than a 3.6KW element!

The controller means the pump only runs when the water in the solar collector

is warmer than that at the bottom of the tank, so it isn't running all

the time. In practice, the pump cycles every few minutes on a sunny day;

the stronger the sun, the longer the pump stays on. The Wilo pump was designed

for central heating systems so it's overkill for this application. It has

three speeds, which are actually selected by introducing different amounts

of capacitance in series with the motor. As it is, the pump does

not remain on continuously during hot sunny days, which indicates the speed

is not too slow.

The Wilo circulating pump. It has three speeds, the

lowest of which is used for this application. It

is important to make sure the proper unions are supplied when purchasing

one of these. Do not use the cast iron body version (intended for circulating

anti freeze solution) as it will rust, causing impeded flow, as well causing

rust particles to interfere with the one way valve.

Use the bronze version instead.

What I did find very useful was to look

at installation instructions for commercially made water heaters, in particular,

the Rheem

Loline which is a solar retrofit.

Evacuated tube collector installed on my roof. Note

the photovoltaic panels in the foreground.

The Installation.

First thing was to assemble the stand

and mount it on the roof. The stand is stainless steel and the roof is

zincalume. To those outside Australia, this is a zinc/aluminium material

with similar appearance to galvanised steel and is used for the same applications.

Given the corrosion possibilities with dissimilar metals in contact with

each other, I mounted the stand on neoprene pads before screwing it to

the roof. I simply obtained a sheet of neoprene from Clark Rubber and cut

it to suit.

It was rather convenient that the roof

area where the solar collector was to go, was right above the laundry where

the hot water tank is. Thus there would be a short vertical run of pipe.

There is approximately 10m of pipe in the circuit. To start with, I used

green lagged copper tubing for the pipe run. All the fittings were designed

to take 1/2" tubing. The short length of copper pipe protruding from the

heat exchanger manifold is a non standard size in Australia. Compression

joiners to connect this to 1/2" tubing were supplied.

Getting the pipe through the ceiling space

was the most tedious part as there was a piece of framework that had to

be cut away above the ceiling cornice. Once this was done, the pipes were

installed and the roof sealed with a Rooftite ( a neoprene gland attached

to the roof with stainless steel screws and sealed with silicone).

I was a bit concerned about mounting the

pump due to its weight and the fact that it was meant to be supported only

by the connecting pipes. The pump was not supplied with the correct unions

either. Instead were just simple 1/2" to 1" reducers with home made silicon

washers to seal the whole thing. I had to purchase the correct unions elsewhere.

I decided to mount the pump on a board with pipe clamps.

The plumbing was straightforward until

I attempted to make the five way valve. The way the Edwards tank is constructed

does not allow such a thing to work; not on the cold inlet anyway.

Pump installation and cold water plumbing. This was

the original cast iron pump.

Instead of the cold inlet simply being

a port in the side of the tank, it's actually a connection to an internal

pipe that runs underneath the tank to the centre. How did I find this out?

I tried making the five way valve and

inserting the hot water copper tube but found it didn't go very far.

The design of this tank has the hot water

outlet right in the centre of the top of the tank; not at the side. So,

I could actually shine a torch down and see inside the tank to learn of

its internal construction. Nice to see all that gleaming stainless steel

inside with not a hint of corrosion. How many glass lined tanks would be

like that after 11 years?

It was this top connection that solved

my problem, for this was the logical place to put the five way valve. There's

about 1.2m of copper tube going straight down into the centre of the tank

for the hot water to be injected. The hot water is thus fed into the tank

at the same location as if I'd put the five way valve at the cold inlet.

The diecast box at the bottom contains the relay for switching the electric element and socket for the pump. There is an additional switch that allows the element to be permanently turned off when required. Neon pilot lamps show pump and heating element operation.

Once I'd finished the plumbing, turned

on the water, and got the leaks out of the connections, it was time to

install the glass tubes. The instructions recommend talcum powder to lubricate

the neoprene glands in the heat exchanger, into which the tubes are inserted.

I didn't have this so I tried CRC2-26. This worked perfectly and the tubes

slid into position very easily. Next, the hose clamps at the base of the

stand were tightened to secure the tubes. Finally, the stainless steel

reflectors were attached between the tubes.

At this point I hadn't installed the control

unit so the pump wasn't running. By the time I'd finished inserting the

24 tubes I found the hot outlet on the heat exchanger too hot to touch.

Not my unit, but the Endless Solar version, this shows

how the tubes are inserted into the heat exchanger.

Within a few seconds of turning on the

pump I had to let go of the hot water pipe from the exchanger going into

the tank, as there was a burst of very hot water flowing through it.

It was at this point that I finally believed

these tubes might actually work.

One annoying thing during the installation

was leaking screwed fittings. I used compression fittings or soldered Yorkshire

fittings where possible. Even with copious amounts of teflon tape, the

screwed connections always leak. I've done them up to the point where the

threads are about to be stripped, and yet I can almost count on seeing

a drip when I turn the water on. So annoying did this get I just

ran solder into the threads. Problem fixed! I only did this where serviceability

isn't goint to be affected of course. The real problem is that many fittings

don't have a tapered thread and this is what's really required to prevent

the problem.

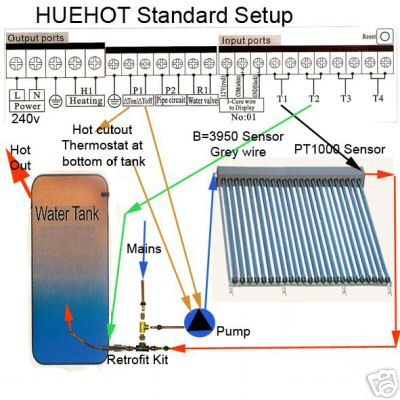

The final part of the installation was

to install the controller. To this are connected three thermistors. One

(designated T1) is inserted into the heat exchanger near the hot outlet

and the other is located at the bottom of the tank (designated T2). The

third thermistor (T3) is mounted at the hot outlet of the tank. Its purpose

is only to activate the electric element if the water has not come up to

the required temperature by solar alone.

T2 thermistor held against tank body by a piece of tinplate secured

under the terminal block.

The default setting of the controller is

such that the pump turns on when the collector temperature is eight degrees

warmer than the cold supply to the collector at the bottom of the tank.

The pump then runs until the temperature difference is four degrees.

Two other functions which are not really

necessary in my installation are frost and over temperature protection.

Should the T1 sensor detect imminent frost (default setting is two degrees),

the pump will circulate warm water until four degrees is reached. This

prevents the pipes freezing and bursting. This would be more applicable

to flat plate collectors, however. The other feature is to turn

the pump off should T2 reach 70 degrees. This stops the hot water flow

under extreme temperature conditions.

Diagram supplied for my solar heating setup. In addition

I have made use of the T3 temperature sensor input and the H1 heating control

for automatically switching the electric element. Unfortunately there's

an important omission: There should be a non return valve either on the

pump outlet or solar collector return to tank. Without this, reverse thermosyphon

occurs at night. The pump wiring via tank thermostat should be ignored.

The controller has a a feature where it

can switch on the element up to three times a day for a specified time

and until a preset temperature is reached. This temperature is sensed by

a third thermistor at the top of the tank (T3), where the water is at its

hottest. I simply pushed the thermistor in between the foam insulation

and the brass T fitting at the hot water outlet. While it isn't in direct

contact with the water, it works well enough as the brass is a good heat

conductor. In practice, I found the thermistor shows about three degrees

less than the water temperature. So, to have the element switch off at

50 degrees, I set the controller for 47 degrees. I have set the controller

so that the heating element is switched on (if it needs to be) at 17:30

for an hour, which is just long enough to get the water temperature up

to 50 degrees, from about 36 degrees, which is typical for a cloudy day.

This works in with my hot water requirements being mainly at night, which

is the best way to use a solar hot water heater.

The controller supposedly can switch 16A

for the heating element, but I find this hard to believe given it's all

on a printed circuit board and the relay doesn't look very substantial.

I decided to make a second box with a

contactor inside, as well as some neon pilot lamps to indicate when the

electric heating was activated, and when the pump was running.

The heating relay inside the controller

simply supplied the low current of the contactor coil which then switched

the 15A heating element. Unfortunately, the contactor having an AC coil

buzzes loudly at 50 cycles. As the whole thing is mounted on a hollow fibro

wall the sound is amplified to a large degree and is very unpleasant. I

fixed that by using a 12VDC relay with 250V 30A contacts. The relay coil

is fed from a small transformer and rectifier. Being DC it is totally silent

in operation. Because I don't always need the water heated automatically,

I put an extra switch in series with the transformer primary.

Electric heating.

It needs to be pointed out that a large

proportion of Australian electric water heaters normally run from an off

peak supply. That is, they are metered separately at a lower rate, but

the supply is only present overnight. This does not suit a solar heater.

Take the scenario where it's been a cloudy

day and the water hasn't heated up for evening use. Firstly, the off peak

supply does not become available until late, and then it takes an hour

or so for the water to actually warm up. Having then heated the water up

to full temperature by morning, imagine what happens if it's a sunny day.

Because the water is already hot, the

solar contribution will be mostly wasted. And the cycle continues. There

will be little saving.

Ideally, the water needs to be heated,

if necessary, prior to the evening/morning use, and only just enough. This

way, the electrically heated hot water is used in the evening and morning

only, and cooled down by mid morning when it's ready to absorb solar heat.

For these conditions, I've found switching

on the electric heating, if needed, is best done late afternoon, once solar

contribution stops. 5.30pm is my chosen time. From experience, I find that

only one hour of heating is needed to cover the night and morning usage.

So, the electric heat switches off at 6.30pm.

For this reason, the ideal pattern of

hot water usage is that most of it occurs in the evening, when the water

is hottest, leaving cooler water for the morning, ready for solar heating.

Furthermore, most people run their hot

water tanks at absurdly high temperatures. The default setting is often

70 degrees! 60 degrees is more than sufficient.

I am very sceptical of claims that certain solar powered devices will work in cloudy conditions, and evacuated tube collectors are no exception. The answer is simply that they will provide some heat, but the truth is not to a usable degree. The electric element is usually required after two days of cloudy weather. Having said that, the use of solar collectors on a cloudy day will still save electric power because the element is only heating the tank from say 35 to 50 degrees, rather than starting off at say 18 degrees. It takes less energy to obtain a 15 degree rise in temperature than 32 degrees would require.

What the kit supplier didn't tell

me.

Once into Autumn, something started to

become very evident. My suspicions of reverse thermosyphon at night was

confirmed as the pipes up to the collector remained warm even though the

pump was not operating. With cool night time temperatures outside,

most of the heat accumulated during the day was simply dissipating into

the night sky. I was beginning to think a non return valve was needed,

and as I looked at the installation manuals for the commercially made systems,

it was now quite obvious; they all used one. To put it simply, I was rather

annoyed that not only my kit supplier did not provide or mention the need

for such a valve, none of the other eBay sellers mention it. I eventually

decided on the RMC solar non return valve type SNR502. An ordinary non

return valve should not be used as it may not be intended for the high

temperatures in a solar hot water system. Luckily I'd seen the RMC price

list for this valve before buying one. It was around $57 retail. So, when

I rang up Reece to order one and was quoted $147, I looked elsewhere. Tradelink

in Penrith had one ordered for me in a couple of days, for the correct

price.

Having installed the non return valve,

the change in performance is like the difference between night and day.

The water is still hot in the morning! The pipes running up the collector

are cold at night as they should be, and now I can look at the T1 temperature

reading to see what the outside night time temperature is.

Quite obviously, eBay sellers of evacuated

tube retrofit kits do not understand the finer points of solar hot water.

They are merely importers from China. You are on your own if you buy one

of these kits; do not rely on what they tell you. Check that you have been

provided with adaptors for connecting Australian pipe sizes to the heat

exchanger manifold. If they're not supplied don't buy it unless you have

good lathe skills. You're unlikely to be able to get the non standard fittings

here. Having said that, I've learnt alot from this exercise, and hopefully

my notes here will enable your system to be successful too.

A further 'non mention' was that thermal

paste should be applied to the ends of the tubes where they insert into

the manifold. This not only seemed logical, but again the commercial instructions

specified it. I used ordinary heatsink cream as used with electronics.

Again, an improvement was evident after this was done.

Incidentally, you won't be eligible for government rebates with this kind of DIY conversion. For one thing, the eBay kits are not goverment approved, and the conversion would have to be done by a licensed plumber.

Cheaper power bill.

The first power bill since installing

the solar conversion was interesting. From $223 dropped to $161.

This is a quarterly account and I should point out that the billing period

in question commenced about a month before installation. So in actual fact

the saving might be more. In any case, that is a very pleasing result.

Even through winter, I've seldom used the electric element. Provided the

day is sunny, the water heats. Come to think of it, I've never used it

after a sunny day.

It is hard to believe that in Australia

with its climate that there are so few solar water heaters. They clearly

do work and save a substantial amount of electric power. I've had the electric

element switched on only about five times in about two months. Yet, people

continue to replace their failed (glass lined, of course) off peak or continuous

hot water systems with the same.

Performance.

While this installation has worked well

for me, I need to point out that it is supplying hot water needs for one

or two users. It is realised that the temperature is variable, and

not to expect huge volumes of burning hot water after an overcast day.

On the few days where the water is quite hot enough for a shower, but not

enough to wash dishes properly, a jug is boiled for that purpose (porcelain

type with exposed element, of course). The 1000W jug element run for a

few minutes is cheaper than turning on the 3.6kW electric boost for an

hour.

While the 125 litre tank works for one

or two users who are careful with hot water use, a larger tank is required

for more users if the electric boost usage is to be minimised.

The thing to remember is the tank capacity

is what ultimately limits the amount of hot water one can consume, not

so much the number of tubes. It is pointless to have 36 tubes to heat up

a little tank by mid morning with the rest of the day's heat having nowhere

to go. You will still only get that tank's capacity in hot water, and once

it has gone you have to wait until the next day for more. A larger

tank will however take in that heat and provide a reserve for a couple

of cloudy days.

I think 24 is the minimum number of tubes

that is practical for my part of the world, and that's with what I consider

the smallest practical tank. My rule of thumb would be to use 30 tubes

for a 180-250 litre tank and 36 for a 315 litre tank.

It is possible to simply daisy chain the

evacuated tube collectors if the heat output from one is inadequate (e.g.

use two 18 tube sets to get 36 tubes).

However, care would have to be taken to

see that excessive temperatures do not occur from using too many tubes.

It is simple matter to cover some of the tubes in summer if this occurs.

It is important to realise that high temperatures

are possible with a solar heated hot water supply and while one day the

water feels lukewarm, after a hot sunny day it can burn you. Remember,

the thermostat controlling the electric element has no control when the

water is heated by other means. So, don't just blindly turn on the hot

tap and put your hands under it expecting it to be the same temperature

it was the day before. If a licensed plumber does the installation for

you, a thermostatic mixing valve will be fitted to provide a 50 degree

limit, as this is required for all new hot water work.

It is quite helpful to have the temperature

display where it will be seen. Not only does it give an idea of what to

expect when I turn on a hot tap, but also if I need to think about letting

the electric boost operate before the water gets too cold.

Later problems.

After a bit over two years operation,

the system was starting to work poorly. First suspicion was the non return

valve, and sure enough this proved to be faulty. I dismantled it and found

a lot of dirt inside keeping it open. Even after I cleaned it, it still

did not seal perfectly. So, again all the daytime heat was being radiated

into the night sky. At the same time, I noticed the pump was almost blocked

with its own sediment. Fairly obviously the cast iron body was a poor choice.

Another thing the supplier got wrong.

I contacted RMC about the valve and much

to my surprise sent me a new one for free. Apparently there was a known

fault with some of the valves around the time I bought the original.

It was great to get such service from

an Australian company. With the new valve in and the pump cleaned out,

all was good again.

However, reading operating instructions

for commercial systems got me intrigued to experiment with the pump switching

temperatures. The default for my controller is if the collector gets to

8 degrees more than the tank, the pump switches on. When the temperature

difference drops to 4 degrees, it switches off. It seemed to me that if

the pump "on" temperature was higher, then the water in the collector would

be hotter before it was pumped into the tank. After some experimentation,

I settled on 10 degrees. As for the "off" temperature, it seemed that it

should stop pumping once all the heated water had entered the tank. It

was quite obvious when this happened simply by feeling the copper tube

at this point.

I set the temperature difference so that

the pump switched off just when the water cooled again. This turned out

to be 7 degrees.

Broken Tube.

Around February 2012, I noticed a crack

at the bottom of one of the evacuated tubes. This would have been from

a falling branch. It took several months for the air to leak in; this being

evident from the tube changing to a whitish colour and becoming more transparent.

At that time of year, the loss of performance was not noticeable, but with

winter on the way I decided to obtain a replacement. By now it seemed that

58mm tubes were now the standard, as few suppliers had the 47mm tubes my

system used. Luckily I found someone with a few old tubes left over and

bought a couple of spares.

New Pump.

Another 3 years later, and again it was

back to reverse thermosyphoning at night. This time I decided to do several

things. As before, the pump was clogged by its own rust, so I decided to

finally get a bronze bodied one. And again, the one way valve had failed.

The supplier where I got the new pump from happened to sell a different

version of these, so decided to give it a try.

If it fails again, I will try a passive

method of preventing reverse thermosyphon. It's a method I've seen with

one commercial system. Briefly, the incoming hot water pipe from the collector

is formed into a U shaped loop, the bottom of which is below the connection

at the tank. The idea is that if this part of the pipe is left not insulated,

it will be cooler than the water at the connection. And heat does not flow

downwards. In theory this will prevent reverse flow. Another option I have

considered is a solenoid valve connected to the pump supply. However, such

a valve has to be able to work at the high temperature and low flow pressure

in the system.

The third modification was to install

a flow meter, as the rate at which water flows through the collector has

an effect on performance. Also, being able to see the flow rate allows

one to see if any blockages are forming.

New bronze bodied pump. One way valve is immediately above the outlet

connection, followed by the flow meter.

Small screw at top of flow meter controls flow rate.

The flow meter consists of a perforated

spring loaded disc. The water pushing against it opposes the spring force,

and thus the disc moves. Alongside is a calibrated scale to show litres

per minute. It appears the standard recommendation is a flow rate of about

100ml/min per tube. A screwdriver set ball valve sets the rate of flow.

Since installing the new pump, and now

being able to adjust the flow rate, I have gone back to the default of

8 degrees on and 4 degrees off, and have set the flow rate to 1.5 litres/minute.

This has made a huge improvement in performance.

It seems that my experiment of increasing

the temperature before the pump operated was flawed. This is likely to

be because there's a lot more time in between pump cycles which not only

gives time for the water in the pipe between the collector and the tank

to cool, but also while waiting for the pump to run, the solar energy isn't

actually going into the tank.

So, to take in maximum energy, it appears

best to have the pump run as much as possible while keeping the collector

temperature just above the tank temperature. This is effectively what happens

with a thermosyphon system. This means having the pump switch off temperature

not much above the tank temperature, and setting the flow rate slow enough

so the pump is almost running continuously on a sunny day at the peak of

summer.

Conclusions.

There is no doubt that solar hot water

works very well and I would now never use any other system. However, in

view of what I have learned with my system, there are some important points

to keep in mind: