Good thing I didn't drive it home!

24/8/25: Replace plugs to get started. Fit hip pads adjacent to front seats.

25/8/25: Adjust voltage regulator

for 7.2V at battery. Was 6.6V. Headlights very dim unless charging. About

1.56V measured. Indicators did not work unless engine running.

Replace windscreen to cowl seal.

Notice front right brake hose leaking.

Good thing I didn't drive it home!

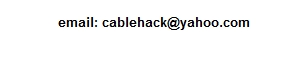

27/8/25: Examine wiring - mistakes

noted. Voltage regulator fed into the system via 20A horn circuit breaker.

High resistance between battery and ammeter responsible for dim headlights

and inoperative indicators.

Brake light not through ammeter. No circuit breaker for light circuit.

Wiring gauge too small for 6V in some instances.

Rewired ammeter.

28/8/25: Reconnected 5A circuit breaker for fuel gauge, and 20A circuit breaker for horn. Better access to C.B.'s if speedo removed. Need to check regulator adjustment again in view of incorrect wiring found.

30/8/25: Made bracket to attach

30A C.B. to light switch.

Terminal broke off brake switch - previous repair with solder.

Started on indicators - fitted 6V lamp into switch. There was an unconnected

12V bulb there.

Original circuit breaker is no longer available, so adapted modern

generic type.

1/9/25: Brake / park light filaments

on RHS found to be reversed.

Indicator bulbs on rear too low wattage (3W) for flasher to work correctly.

No output from pilot light (P) terminal on flasher because of this. Replaced

with 21W.

Brake lights need rewiring.

Bodgie trailer socket connection in wiring noted.

Reinstalled indicator switch.

2/9/25: Made new wiring harness

for rear lights.

Found number plate light bulbs to be 12V. No wonder they were dim.

Short circuit found in LHS brake light socket.

Decided a rewire was in order when I saw this.

3/9/25: Finished rear light wiring

and ran new wire to LHS indicators.

Made buzzer circuit for indicators.

Reconnect horn - crimp connector came off wire.

Mixture of old and new wiring.

6/9/25: Replace brake switch and

install new connectors for it - strange type of bullet connector?

Fix choke cable - crushed under carburettor clamp.

Replace battery clamp bolts.

High and low beam headlight connections need to be reversed. High beam

indicator is on with low beam.

Installed 10A blade fuse for indicators.

8/9/25: Reverse headlight beams.

Degrease starter Bendix - engagement not always as it should be. This needs

further examination. There is a possibility the Bendix has the wrong number

of teeth.

Readjust voltage regulator to 7.2V now that it's connected correctly.

Check steering box mount to see if angle of column can be raised. It's

already at its limit.

Install surround ring for dip switch.

Install new air hose and clips.

Handbrake cable observed to be sticking.

Starter motor out to examine Bendix.

9/9/25: First order of parts from

Milspares.

Dismantled front brake hoses. RHS blocked as well as leaking. LHS hose

same as Hilux.

11" hose in box of parts too short for RHS. S shaped solid brake line also

too short for RHS.

11/9/25: Get new brake hoses made

by Pirtek.

Milspares parts arrived.

Attempt to connect brake hoses. Need thinner retaining clips. Used new

S shaped brake line on LHS.

LHS front wheel bearing needs replacing.

Ordered clips for brake hoses from eBay.

12/9/25: Replace steering wheel

with 15" version. Splines tight.

Replace handbrake cable. Not sure about clips on end.

Remove RHS freewheeling hub in preparation for hub/drum removal. This was

necessary to access the wheel cylinder which was likely full of sludge,

given the condition of the associated brake hose. (All wheel cylinders

had been replaced by previous owner).

Removing orignal steering wheel. This is the 17" Sheller type.

New 15" steering wheel in Willys style. Much more comfortable for

tall people.

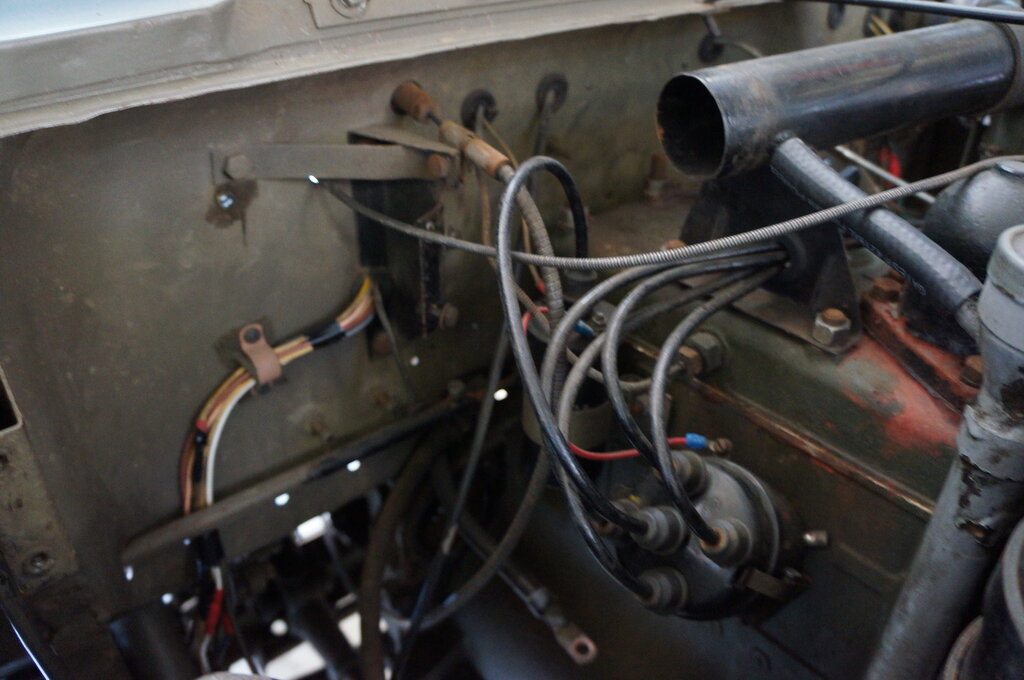

13/9/25: Remove RHS front hub to

access wheel cylinder.

Remove hex freewheeling hub screws, then nut on axle.

Remove six 9/16" bolts on FW hub - really need thin wall socket.

Remove big nut after bending washer.

Remove next nut and pull off hub.

Remove brake shoe cams then shoes.

Remove wheel cylinder - some sludge inside and starting to pit.

Clean up and reassemble.

Note sure about axle end play - it's 3mm.

Cover off freewheeling hub.

Access to wheel cylinder.

Front LHS brake hose replaced.

Front RHS brake hose replaced.

15/9/25: Removed rear brake lines.

Attempted to install new brake lines but different bracket for T junction

on diff has been fitted in different location.

Ordered correct bracket and two hub washers for future front wheel work.

18/9/25: Installed new T piece bracket.

Installed brake lines after much bending.

Installed hose retaining clips.

Replace generator earth screw - it was a random self tapper and should

be a proper screw.

New rear brake lines.

20/9/25: Bleed brakes. Front LHS

hose, rear T piece, rear flex hose all leaking and needed more tightening.

Note that new bracket for T junction inhibits access for flare nut spanner.

Will need to cut away part if this becomes a problem.

Not keen on access to fill master cylinder. Used syringe and short tube.

Reinstalled battery. Horn sounded. Short circuit somewhere.

Test fit all three vehicles in garage. They all fit!

22/9/25: Replace horn wire in steering

column. Switch erratic but improved it. Horn relay via ignition might be

good.

Adjust handbrake - seems to work OK.

Examined shock bushings. Seems to be generic type same as Hilux.

23/9/25: Get shock bushings from

Repco. Install on front shocks - definitely same as Hilux.

Discover rear shock bushings are different and unable to find replacements.

Australian made Monroe shocks had been fitted a long time ago.

24/9/25: Order new rear shocks -

the bushings for the official ones are readily available (and come with

the new ones).

Replace steering box gasket.

Replace transfer case mount.

25/9/25: Refill steering box - used

syringe.

Tried to adjust play out of steering box, but binding beyond centre. Had

to back off, but has play. Suggestive of the worm gear or steering sector

shaft pins being worn. Will have to examine.

Replaced rear shocks. Compressing the bushings to get the split pins in

was very difficult and had to use all sorts of bodgie methods.

27/9/25: Disconnected rear RHS leaf spring from chassis bracket. Attempted to weld the bracket. Total disaster. This bracket being bolted only, and not welded, was one of the things it failed on with the previous owner's registration attempt.

The spring mount before my welding attempt. It is supposed to be

welded as well as bolted. I found the limit of my skills with this one!

29/9/25: 2nd attempt at welding

- this time with DC welder. Yes, the arc was easier to strike and maintain,

but the result was still a total disaster. Ground off the embarrassment

before anyone might see it.

This is my first stumbling block and not sure what to do.

30/9/25: Got spring back in since

I had given up with welding it, and the Jeep needed to be mobile.

And here's a handy hint: Disconnecting

and reconnecting the leaf spring is a right pain in the arse. It is not

like the book says. Problem is the spring curves inwards when under no

load. Needless to say, the eyes no longer line up.

After spending half a day trying to get

the spring back in, I took a different approach. By disconnecting the axle

from the spring, the spring is only tethered on the other eye on the U

shackle at the rear. The spring is free to move forward so the chassis

eye lines up.

Then, it's a simple matter of jacking

up the spring so that it meets up with the axle mount, and reinstalling

the two U-clamps. The Jeep must be supported by stands under the chassis

rail, and also another jack under the diff whilst doing this work. Once

I did it this way, it was very straightforward and everything went into

position.

5/10/25. LHS front wheel bearing

replacement. I had previously noted a rumbling sound and feeling of roughness

in the LHS front wheel. Such symptoms point to the wheel bearing.

First thing to do is to remove the freewheeling

hub.

Rust in freeewheeling hub.

There was a lot of light rust inside. Also, when I removed the front wheel, surface rust was present where it mounts on the hub. I had noted photos from the previous owner showing it stored in a carport. The LH side of the Jeep faced the open side of the carport.

Jeep had been stored exposed to the weather.

Freewheel hub removed and still more rust.

Rusty water had penetrated into the hub.

Bearing rusting and pitting.

No wonder there was a rumbling sound. The

bearings were quite pitted on the rollers. It was not difficult to replace

them, although it was an all day job. Conveniently, new bearings and seals

had been supplied.

Note that for the LHS of the Jeep, the

wheel nuts are removed in a clockwise direction.

When replacing the bearings, tighten the

first nut to 50 ft. lbs, then back off 1/6 turn (i.e. one flat of the spanner).

This is supposed to apply the correct preload. It certainly felt like it

did - and it rotated smoothly.

The next nut (after the bendable washer)

is also done up to 50 ft. lbs.

There was about the same amount of axle

end play on this side as the other.

The freewheeling hub had to be dismantled and rust cleaned out. It was noted the spring clip for retaining the sliding part of the hub had rusted and will probably break apart at some point. It is not super critical.

The Selectro freewheeling hub instructions

imply tightening the axle nut to 10-15 ft. lbs. On the RHS this was impossible

if the nut castellation was to line up with the split pin hole. In that

instance, it had to be done up to around 50 ft. lbs. However, for the LHS,

the slot lined up with less than 20 ft. lbs. (the lowest my torque wrench

reads).

An interesting thing observed was the

brake light came on while doing this work. I can only put it down to pressure

on the wheel cylinder while removing the drum actuated the switch (it's

a hydraulic switch). Once the drum was back on, stepping on the brake pedal

fixed it.

7/10/25: Time to deal with the steering play! First thing was to get the steering sector shaft out to examine the pins for wear. This entailed opening the steering box, ruining the gasket I'd just replaced, and getting all the lubricant out. Getting the pitman arm off was not easy at first. I attempted to remove the whole steering column with box, but couldn't get it out with too many things in the way. It turned out that removing the entire fender was the solution. It's easy to remove and service access is then excellent.

Removing fender gives good service access.

However, back to the pitman arm removal

- my cheap puller is just that. The problem is the arms spread apart under

tension, then they slide down the side at an angle, gouging into the metal.

Of course, it doesn't come off.

A YouTube video showed one of these pullers

with a piece of angle steel welded across it so the arms can't spread.

Since I didn't have such a piece of angle, and as I've learned, my welding

skill is pathetic, I tried a similar method using a G clamp.

G clamp stops arms spreading under tension.

With the pitman arm removed, and the steering

shaft sector out, it seemed the pins were in very good condition. I know

the previous owner had work done on the steering box. He mentioned sending

it to someone, and it seemed that the bushings and seal were replaced.

That leaves the steering shaft/worm drive.

And here I found something rather disconcerting. I wanted to measure the

steering shaft length because of my suspicion it might be from a CJ. If

it had to be replaced, I'd need to check I got the right length replacement.

The original MB/GPW should be 40.5", but I understand the later CJ's used

41.5".

Steering shaft is 37" instead of 40.5". Steering column has been

cut where the horn brush would be mounted.

With the steering column out (after removing the battery and its carrier), the whole story became clear. I was rather surprised to find the steering column was 37"! I wasn't aware of any Jeep model using that length. Then I noticed how the steering column had been clamped to the steering box. It had been clamped where the horn brush connection is located on the MB/GPW. The steering column had been cut and shortened! Closer examination revealed the shaft had been cut and welded.

Cut short and welded back together.

I examined the worm drive. Yes, it did look like there was some wear.

Wear visible 2nd groove from the left.

After all of that, there was no doubt the

steering shaft and column had to be replaced. Not just because of the wear,

but with 3.5" removed, it was no wonder the position of the steering wheel

seemed strange. Out of curiosity, I temporarily mounted the column back

in the Jeep, and moved it up 3.5". What a difference! It turned out I didn't

really need the smaller steering wheel.

Why was it shortened is something that

will probably never be known. I have seen this kind of thing done in the

Model T world because the seats are not adjustable.. I can only think a

previous owner was very short.

What to do now? New steering shafts are hideously expensive if you want a good repro; around A$800 by the time one got here from the U.S. Cheaper ones, around $250, are available from India on eBay, but the quality is unknown. There was some mention of the forum of some repros not being made with correct hardness. The local supplier I had been using so far, Milspares, had new ones listed, but out of stock. A phone call revealed they were N.O.S. and had now run out. M.V. Spares didn't have any listed, and another supplier I know of, Marathon Spares didn't have them listed either. However, they do deal with second had parts. I emailed them to tell of my tale of woe, and I was much relieved when a reply came back saying they did have a good second hand one. I ordered it of course, and also a new steering column from Milspares, since Marathon didn't have that.

16/10/25: Steering shaft arrived. It looked in excellent condition.

You can see what the problem is here. "Original" column and shaft

at top.

I was pleased to see the 'new' steering

shaft had a hole up the centre of the worm drive so would be compatible

with the CJ horn arrangement. As can be seen in the above photo, the brush

type horn contact was present on the replacement. However, I had to remove

it because it's in the way of the bearing cup and snap ring for the upper

bearings. Also the bearing retainer that the steering column clamps to

wouldn't fit over it. In any case, the CJ setup is much better. There's

more possibility with short circuits or bad contact with the original brush

type horn contact.

While the upper bearing cup was present,

I replaced it since I had a new one. Similarly, the lower cup was replaced

along with all the ball bearings. I was one ball short (the packet had

previously been opened) so had to reuse one. There was no visible wear

in the originals, but replacing them eliminates that possibility causing

steering play. The bearing cups are held in place with snap rings. It's

a fiddly operation to remove them, but not hugely difficult.

Bearings transferred to replacement shaft. Note horn contact at

left. This was removed.

The next job was to set the bearing preload for the steering shaft. This is done with shims.

Steering box in vice while preload is adjusted.

The shims are adjusted between the top bearing and bearing retainer so that the shaft turns freely, but without any vertical play. I had to remove three shims.

17/10/25: Apply silastic to upper bearing retainer. Reinstall sector shaft - feels like it has a good fit.

Ready for gasket and cover.

Install gasket and cover. Noted adusting pin has been gouged after I readjusted steering box previously. Will grind the damaged part for temporary use, and replace with next parts order.

18/10/25: Assemble steering column to steering box. Find that the upper steering shaft bearing (at the top of the column) was a tight fit on the steering shaft. Had to hammer it on with a piece of wood. Found that the whole thing can be slid back in through the firewall if the plate surrounding the clutch pedal is loosened off.

Steering box back in.

The steering was then centred. Counting

the turns of the steering wheel end to end, it was just over four turns.

The steering wheel is then turned two turns so the sector shaft is in the

middle. Then, with the front wheels straight ahead, the pitman arm was

attached.

Pitman arm nut is done up to 100 ft. lbs.

It was found the alignment of the steering

box to the chassis is now slightly different. If the steering box was bolted

flush to the chassis rail as before, the steering column was to the left

on the dashboard side. Some packing (e.g. washers) will be needed between

the steering box and chassis rail to adjust this. For now I've just tightened

it down as is, to get the Jeep drivable.

So, why did the steering box have a better

fit before? It appears the steering column had been bent to suit.

Slight bend in steering column towards the right end.

The fender was replaced, and the regulator and battery installed.

New steering column gives more steering wheel clearance. Horn wiring

yet to be done.

I'm happy with the results. The steering is much tighter and the amount of play is what I would expect. There's not much else I can do if the inspector complains...

19/10/25: Found the brake lights on when I came back home after a day out with the Model T. No idea how long they had been on for, but the battery was 6.22V, so probably not too long. A possibility is the pedal freeplay needs adjustment. If that doesn't fix it, I will make a switch operating off the pedal. I've never liked hydraulic brake light switches.

20/10/25: Found no clearance between brake pedal and master cylinder piston, so readjusted. Switch appears to be working OK now. Left battery maintainer on just in case the brake lights come on all night. Reinstalled horn wiring. Lengthened wire for longer column. Horn switch bad design. Floating metal washer can move to the side shorting against steering wheel nut. I soldered it to the central contact. When threading the wire it needs to come up from the steering box. Remove the outer horn contact from the steering shaft or it will be a pain to get the wire through - I realised this after I did it the hard way.

21/10/25: Improve fitting of steering

box to chassis rail with packing washers. Centre steering wheel rotation.

Install new floor seal for steering column.

Remove starter motor. Number of teeth is 10 which is correct for a 97 tooth

ring gear. Measure ring gear height which is 5/8" and therefore has 97

teeth.

23/10/25: Ordered new Bendix from Marathon Spare Parts.

29/10/25: Commenced work on Bendix replacement.

Armature and Bendix extracted from starter motor.

Getting the starter motor out and apart is not difficult. As I noted previously, it all looked in very good condition. I noted the locking tab washers had been reused, since the locking tabs were broken off. Obviously, this had been worked on before.

Hole in shaft has been damaged.

Where the bolt secures the drive to the shaft required a little bit of grinding with a Dremel to get the Bendix off. It seems that in the past the bolt might not have been tight, because it elongated the hole in the shaft, with which it engages, and left a burr on the edge.

Hidden under the spring was this broken part.

Once off, we find that looks are not what they seem. Under the spring was the broken part shown above.

New Bendix installed.

I was impressed with the quality of the

new Bendix. It also had the right number of teeth (10). There are many

Bendix drives supposedly for MB/GPW Jeeps which have 9 teeth. Incidentally,

these always seem to be the cheaper drives from eBay and the like.

10 teeth will give a faster rotation of

the flywheel anyway, even if the 9 tooth versions do actually mesh properly.

Starter motor ready to go back in.

Reassembling is not difficult. As always,

the brushes need to be held out of their holders while the armature is

reinserted. An interesting feature is a bushing in the bell housing to

support the end of the starter shaft.

This simple job has totally transformed

how the Jeep starts. A nice quiet engagement of the starter every time.

I was amazed at the difference. It's probably one of the most significant

things I've achieved in terms of how it performs.

Anyone who has a Jeep with a grinding

Bendix (including whoever bought the Queanbeayn Jeep), should dismantle

the Bendix and check the drive parts under the spring.

Now is a significant timeline in my work - the mechanical and electrical work is pretty much finished. Only the chassis work with the spring brackets remains.

3/11/25: Put bolts in for RHS front

spring bracket. It appears originally, that for Ford GPW (which my chassis

is), these brackets were riveted as well as welded. Willys MB appears to

have used bolts. The result of this is access is difficult with the GPW

chassis. The chassis is boxed in, and the nearest access hole is a few

inches away. That means one can't just reach inside and push the bolt through.

And, no, there was no chance I was going to use rivets!

First thing to do was make sure the holes

were clear. The one towards the front was, but the rear one needed a bit

of drilling out. For the Willys chassis, the bolts are 3/8" x 1.5" UNF,

and that's what I used here.

Bolt on end of coat hanger wire allows it to be inserted remotely.

I used a short length of coat hanger wire,

looped around the bolt for about 3/4 of a turn. It needs to be tight, otherwise

the bolt will just fall out as you try to get it in the hole. The idea

is then once the bolt is through, and captive with the nut, to push the

wire so it unhooks.

This is the kind of job that is extremely

difficult and irritating unless you've got patience and dexterity. After

some practice, I was able to get the front bolt in. It was a little bit

tight, so pushed down on it with a narrow ring spanner to get it through.

Only enough thread needs to come through to attach the nut, and then the

whole thing can be pulled through. Remember to unhook the wire first! I

pushed on the bolt with a screwdriver, to stop it turning while the nut

was put on. Once the thread came through the other side of the nut, I used

pliers to grip it. As the nut tightens against the spring washer, it stays

still.

Front bolt in position.

The rear bolt went in similarly, but is further from the access hole. I also had to remove one of the steering box bolts first. I was getting good at this by now, and didn't take as long to get in.

Front spring bracket done!

5/11/25: Weld outside of rear spring bracket. I decided to give it another go - this time practicing on another piece of steel first. I used a star picket since I had one handy, and it's of similar thickness. It turned out I needed more current that what I had been using before. About 80A was right, and made a reasonably neat weld. I found on the Jeep that 95A was about right for the bracket.

Outside weld done.

6/11/25: Did the weld on the inside of the chassis rail. Check tyre pressures - all down to around 20 psi. Pumped up to 35 psi.

Inside weld. The original Ford weld is only in the middle third

and that's what I've duplicated here.

Now, for the anticipated comments from the 'welding police' - "He can't weld for shit"...Well, it's not something I've ever been trained in. I could say the same when someone has difficulty with something electrical. Anyway, the bracket is welded, it's strong, and it should pass registration.

7/11/25: Replace missing grease nipple on LHS front of rear spring. It is 1/8"-27 NPT. I obtained replacement from Pirtek. Painted welds.

8/11/25: Grease chassis. The difficult

part of this was the grease gun developing air locks from when I refilled

it. Very messy!

Move black out marker light connection

to rear park light connection on headlight switch. As originally connected,

the B.O. markers went off when the headlights were on. For civilian use,

where the B.O markers take the function of parking lights, it's best to

have them on with the headlights. We want all the visibility possible!

Paint steering arm where the paint had

been dissolved by brake fluid.

Check engine oil.

Check oil in both diffs.

9/11/25: Check transfer case and

gearbox oil levels. Like the diffs, these use 9/16" square head plugs.

It turns out I have the early Willys gearbox, since the plugs are on the

RHS. Later were moved to the LHS. I can see why - the access is awful.

However, I did manage to open the fill plug by using an 11/16" ring spanner

to get it to initially loosen. Then used an 11/16" socket on an extension

to fully undo it. Fortunately, it didn't need any oil added.

Check water level - OK for now but could

do with a flush.

10/11/25: Enquiries made about registration

with a private car club, and have started the paperwork process. It seems

like a good scheme, although of course there is a restriction of 60 days

per year.

Pink slip (registration inspection) booked

for 14/11/25.

14/11/25: Pink slip inspection.

All went well. My first time driving the Jeep in traffic. The steering,

brakes and clutch are all completely natural - I was operating them without

even having to think. I have to get used to the gear shift pattern - first

and reverse needs to become second nature. But, I didn't stuff up too badly.

The return trip was good - got it into third gear.

All the really hard work is done, and

next is the back and forth bureaucracy of the registration and club paper

work.

19/11/25: Replace tool box locks with lockable type. MV Spares was the lowest cost source of these.

23/11/25: Modify dash lamp shields by widening the slots. This is to improve gauge illuminination - previously non existant. Cleaned plastic back window in roof. This roof is an Australian type, since it has provision for side curtains, as well as having the plastic window insert. Normally, there is a square hole with no plastic.

8/12/25: Registered at last! I went to Katoomba this morning to hand over the paperwork, which was accepted without any problem, and a new set of plates and a log book were handed to me.

My first experience with historic registration.

Registration has always been the most unpleasant aspect of owning cars. Not fuel prices or the cost of insurance - no, it's getting them registered. It took over a month to get the Model T registered because of a pedantic inspector. This time, with the Jeep, a problem existed with paperwork, with each bit of paper having a different make and model. The previous owner called it a Ford GPW on the receipt because he thought that the Ford was more desirable and valuable. Problem is, it says "Willys" on two parts of the body; one quite obvious (the data plate). The previous Victorian registration was as a Willys MB. Then, the pink slip called it a "Jeep" GPW. None of these names or models are incorrect as such, but when a cop pulls me over and sees Willys, it's a problem if it's registered as a Ford. Also, the registration people are going to be confused when across the paperwork it's Ford GPW, Jeep GPW, and Willys MB. Not knowing anything about Jeeps, you can imagine how the pedantic nature of the public service is going to react to that. Anyway, after much correcting of paperwork, it all went through OK. Now, for the next few jobs - battery isolator and tyre flaps.

9/12/25: Installed battery isolator switch.

Voltage drop was too much.

I chose a knife switch type. The green

knob type of switch has proved to be unreliable. I've got one on the Model

T. Problem is the plastic melts and creates a gap between the fixed contact

and the screw down part. I've had to repair the one on the Model T once

already. The fact that the plastic melted means there's excessive voltage

drop.

Unfortunately, while the knife switch

was simple to install, and doesn't have the problems of the other type,

it too had a voltage drop. This is to be expected of course. In this case

it was around 200mV while starting. That's 3% of the battery voltage, which

I felt was unacceptable.

In fact of all days, in the mid 30's,

the engine should have been very easy to crank, but as soon as I tried

it I noticed a slight drop in cranking speed. It would have started, but

there's no leeway for colder weather, etc. 3% might not sound like much,

but for a 6V system it's significant. I removed the switch, and cranking

speed was back to normal. I think I'll fit this switch to the Model T where

cranking current is less.

Fact is, the Jeep has survived all its

life without an isolator, and my main reason for installing it was to prevent

operation of horn and lights when parked unattended. Those functions can

be done with relay circuits.

10/12/25: Made up new bracket to support bimetallic spiral for the hot air bypass valve. There was a home-made bodge there which did not allow for correct operation of the bimetallic spiral.

In cold position valve is open.

When hot, valve is closed.

The exhaust manifold opens to the underneath of the carburettor to help the fuel vaporise when started cold. There is a thermostatically operated valve which closes off this opening once warmed up. It is controlled by a bimetallic spiral. You can see a weight on the end of the lever - this keeps the valve open unless the bimetallic spiral is heated.

15/12/25: Install spare wheel lock. Conveniently, the key is the same as the toolboxes.

No idea if this is the correct way to attach the chain to the wheel

bracket.

17/12/25: Fire extinguisher: A repro bracket came with the parts, but alas the diameter it takes is 77mm. All the modern small 1kg type of fire extinguisher are about 80mm. I decided to adapt a modern extinguisher bracket, and make my own to mount it to the Jeep. For this, I made the three cross pieces which bolt onto the fender. Then made the vertical piece onto which the modern extinguisher bracket could be mounted. The mounting holes were identical, so I could fit the repro bracket if a 77mm diameter extinguisher ever appears.

Made up my own bracket to take a modern extinguisher.

18/12/25: First test drive since registrations. Covered almost 18 miles. Very happy with how it drives - except there is a problem with the gear shifting. Sometimes it is impossible to get it into 2nd gear. No problem moving the gear stick over the right side, but you just can't move it forward (2nd) or back (3rd). Once in 2nd, there was never any problem moving it between 2nd & 3rd. It seems from some forum comments there might be a plate on top of the transmission which wears.

Another thing I have to work out is how to get into 1st while under load going up a hill. One hill nearby can only just be done in 2nd, but would prefer 1st. I think I would need to be in 1st to ascend Scenic Hill or Brown's Gap Rd at Lithgow.20/12/25: Install fire extinguisher. Six holes are drilled into the fender - the diagram of where they go is comes with the nuts and bolts supplied for this purpose. I painted the screw heads before installing. Four of them are hidden behind the shovel anyway.

Four of the screws visible.

Incidentally, the screws are the same as for the side mirrors - useful to know when they don't turn up in the search on the parts suppliers sites.

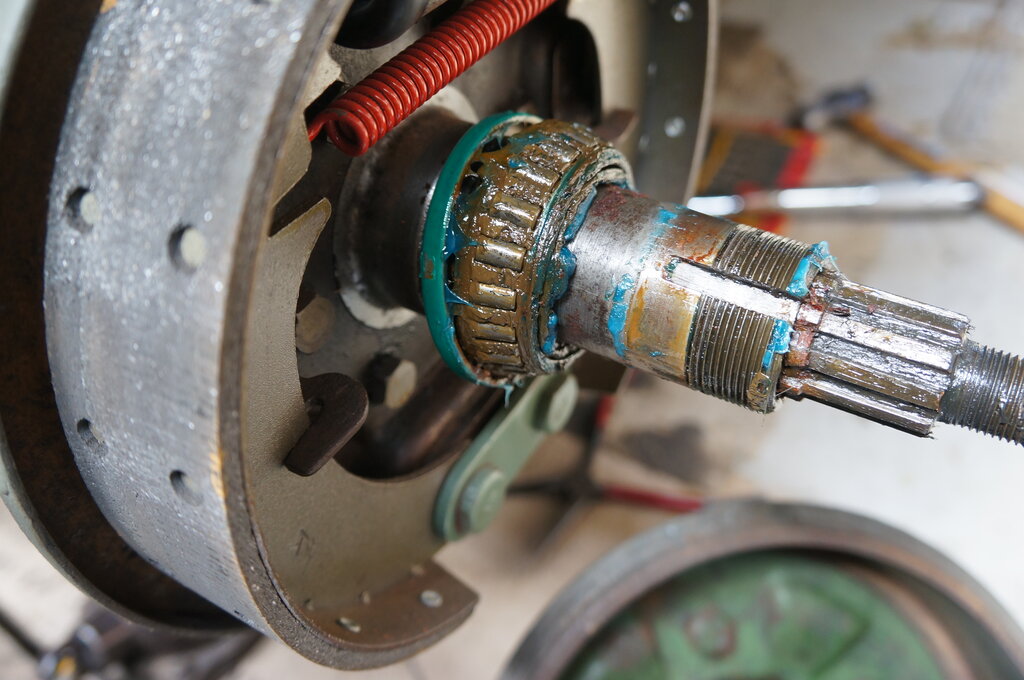

22/12/25: Gearbox day today! I put

a question on the G503 forum about the sometimes difficult shifting into

2nd and 3rd. General thoughts are it's likely to be something in the tower

or the shifter plate.

Took off the floor cover for the first

time and was rather surprised to see a 1958 rebuild plate:

Rebuilt 3/3/58.

The fact the rebuild plate is on the bellhousing

makes me think the transmission was rebuilt at the same time. The piece

of wire emerging is a curiosity, and a potential worry. Is is holding something

precariously in position, which will never work again lest I disturb it?

But, onto the gearbox. First thing to

do was unscrew the gear stick ("cane" in Jeep parlance).

End of gear stick that engages in transmission.

Next to open the transmission. This is done by removing four 1/2" bolts on the top.

Gate plate under the cover.

Shifter plate in top of transmission. 2nd & 3rd on the left,

reverse and first on the right.

Side on view of shifter plate. It looks a bit rough, but then realised

someone has added the U shaped part to prevent the sides spreading from

the forces from the gear stick.

Inside transmission without shifter plate. Left rail is 3rd up,

2nd down. Right rail is reverse down, 1st up.

27/12/25: The guys on the forum haven't noticed anything unusual, except the slotted head screw which secured the shift fork to the shift rail. You can see it in the upper left of the photo above. Notice the screw for the fork in the lower right looks different. Apparently the screw should take a Bristol key (like the lower right). I took it out and found it's machined the same where it engages the shift rail, so highly unlikely to be the problem. So, I put it all back together.

Also found out the wire coming out of the clutch inspection cover is wrapped around the clutch release fork. I think that was to hold it in position during assembly. It is harmless and easier to leave it, so I did. I had to drop a light bulb down inside the bellhousing, and use a mirror to see it.

Look in the mirror for the piece of wire. It's wrapped around the

clutch release fork.

I did a short test drive and found no difference. The only meaningful thing was that I noticed when it wouldn't go into 2nd, if I dropped the revs right down, then it did. However, the revs had to be too low - more what you'd use for 1st gear. I wonder if the synchros are the problem?

Tightened the fan belt. Noticed the two hoses from the oil filter should be replaced.

30/12/25: Installed thumbscrew chains for top bows. No instructions, and the absence of other photos anywhere made this difficult, but I think I got it right. All the photos I found were of the GPW type. Mine are MB which are quite different. I've noticed that Jeep parts, either in the catalogs, or in the packets themselves, lack instructions more so than Model T parts.

31/12/25: Test drive - locked in 1st gear. At this point something has to be done about the gearbox.

3/1/26: Tried to simulate fault in gear box by moving shifting rails around with top off. It could be the 1st / reverse rail is not always going into neutral. This would prevent the interlocking pin to allow movement of the 2nd / 3rd rail.

11/1/26: Commence removal of the

transfer case in order to replace the 1st / reverse shift rail. Today I

got as far as removing the shift levers, and the drive gear on the shaft

from the gearbox. A separate article will follow detailing this procedure.

The big nut is 1-5/16" and is done up

to over 100 ft lbs. It was not easy to remove, requiring a jack between

the chassis rail and torque wrench to loosen it.

Inside transfer case with drive gear removed. The two shift rails

are visible at the top. Unfortunately, the rails can't slide out here because

of the casting at the back.

12/1/26: Remove front drive shaft, speedo cable, rubber transfer case mount, clutch release mechanism. Drain transfer case and transmission. Remove rear drive shaft.

13/1/26: Commence removing transfer case after securing mainshaft in transmission.

14/1/26: Replace 1st / reverse shift

rail, ball and spring. Replace ball, spring, and fork screw for 2nd / 3rd

shift rail. Grind interlocking pin channel in transfer case so pin slides

freely.

Reinstall transfer case.

20/1/26: Replace seat cushion screws. Non-originals had been used, and since I had the originals in the box of parts, they were installed. The exception was for the front seat cushions since holes had been made in the canvas in the wrong locations. I left those screws as they were. They should be nuts and bolts there - all the other ones are self tapping screws. I was told on the G503 forum that my rear seat cushion and frame is not original, due to the location of the screw holes and that the cushion does not extend all the way to back of the seat. On mine the screws face up and are exposed. On others, the canvas flap hides the screws which face inwards.

21/1/26: Made video of the Jeep. The gear shift problem appeared once. This was better than previously, but still obviously not fixed.

24/1/26: Finish clean out of cooling

system and replace with coolant. I used 33% coolant to 66% rainwater.

Attempt to replace the three oil hoses.

The two short ones were successfully replaced, but the long one wasn't.

It turns out this hose has been custom made to fit the oil filter canister

without an adaptor. When I tried to fit the repro hose, it was too large.

Forum discussion revealed an adaptor is required - and I realised that

being a flared hose fitting there would be nothing for the flare to seal

against without it.

Hose at left is what was already installed. At right is the new

repro.

Old hose shown. There should be an adaptor on the oil filter inlet.

Incidentally, to get at the oil hose connection on the engine block which feeds the filter, it is necessary to remove the fuel pump. It, and the engine mount is otherwise in the way.

26/1/26: Australia Day at Australiana Village, Wilberforce. I display the Model T there. There are always Jeeps as well as other vintage vehicles. One Jeep had a rear seat set up just like mine. It was a slat grille MB. So, it appears it is actually correct for early MB's.

Rear seat as fitted to a restored 1941/42 Slat Grille MB.

Another member on the forum showed a photo of his seat and the screws were also facing up. Then I realised a pattern - all three seat frames with upward facing screws were in Australian Jeeps. It makes me wonder if they were locally made for or by the Australian Army.

27/1/26: Made video about the transmission https://youtu.be/Cvs4JF86ACw

30/1/26: First long drive since I've owned the Jeep. It was a 50 mile (80km) round trip. Keeping in mind the need to find the neutral detent when shifting gears, not once was I locked out of 2nd gear. The Jeep went well, and I drove it to, and around, the Blue Mountains town of Blackheath. There is a slight leak with the fuel pump bowl gasket. I'm finding it a lot like the Model T to drive, in terms of thinking and planning ahead. However, the extra power is appreciated! For highway use, it seems happy at 40 to 45 mph.

31/1/26: A longer drive, to the Blue Mountains town of Lithgow. This is a 77 mile (123km) round trip. I'm getting a lot more used to the Jeep and really enjoying driving it. The extra power over the Model T is noticeable and much appreciated! However, one must drive to the conditions and limitations. Those who know the area will be aware of Brown's Gap Rd and Scenic Hill. The Jeep ascended both those with ease in 2nd gear. The odometer is now up to 156 miles; 127 of those since repairing the gearbox.

2/2/26: Replaced long oil hose. Noticed oil fill tube has been modified. A bracket has been brazed or welded which secures it to a nearby head stud. The nut is missing. Originally there was a clamp around the tube which secured it under one of the oil filter bolts. Also noticed the original MB engine number is partly visible behind the oil filter. Checked voltage regulator. Battery is charging at around 7.2 - 7.4V.

9/2/26: Found spare wheel carrier missing top left bolt. Bolt found wedged between tyre and back panel. Nut found inside tub. Unfortunately, the wheel carrier had cracked in multiple places.

Decided to replace it since welding would never be as strong, and that there would be metal fatigue near the breaks. The wheel is very heavy! New one is of much better construction, stamped out of one piece rather than being folded and welded.

13/02/26: Installed new spare wheel carrier. Included 5/16" spring washers. Some of the 'original' nuts appear to be Whitworth. They don't fit 1/2" or 9/16" spanners, but 13mm will just fit. I believe some Whitworth sizes are the same as metric.

Grey appearance of the paint appears to be due to sun fading. The

new paint has an obvious contrast. Additionally, the wheel carrier is of

a darker shade than the lock, and what I used for the body repair.

17/02/26: Install horn relay so

that horn cannot operate with ignition off. 1) People like pressing horn

buttons on parked vintage cars, 2) The horn switch design is a bit suspect

in my opinion - I don't want it sounding in the middle of the night. Relay

contacts are in the earth return of the horn as per original. Feed for

relay coil comes from the fuel gauge circuit breaker. I noted a self tapping

Phillips screw for the horn terminal that I reconnected. I don't think

that's original.

Reconditioning a trouble light to keep

in the toolbox. It's an ex Toyota from the 1970's. Needed longer flex (the

plug had been cut off as well), and the bulb replaced with a 6V 18W type.

Also cleaned up the metal cage and sprayed it olive drab.