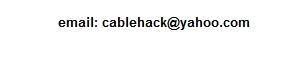

Repaired fuel gauge being tested. The rheostat simulates the petrol tank sender.

Repaired fuel gauge being tested. The rheostat simulates the petrol

tank sender.

When those in the vintage car world learn of my electrical background, it's natural to be asked various questions about automotive electrical systems, and to provide assistance in getting something to work properly.

Gauge always shows Empty.

One such interesting repair was a HD Holden

fuel gauge. As it turned out, there was a design fault which I'll get to

later. The problem as the owner described to me, was simply that the gauge

did not work, always showing "empty". He was suspecting the sender might

be faulty, and it was at this time I got involved.

The basic principle of a fuel gauge is

that the gauge is really an ammeter of one form or another, and it simply

measures current flowing through the fuel sender, which is really just

a rheostat.

For this fault, there can only be three

possibilities; 1) no 12V supply, 2) open circuit gauge, 3) open circuit

sender.

A simple test to start with is to disconnect

the fuel sender at the petrol tank, and see if there's any voltage coming

down the wire from the gauge. If there is, it means the supply and the

gauge are probably OK. In this situation, there wasn't any voltage.

Now it was time to extract the gauge from

the dash. 12V was present at the "bat" terminal, but nothing at the "sender"

terminal. Obviously, the gauge was open circuit.

The two way connector at top left is for the sender and 12V connections.

The face of the gauge is crimped on, but easily removed. Once open I could see a meter movement and a rather darkened 1W resistor.

Open circuit resistor.

The question was, what is the value of

the resistor? It looked like 82 ohms, but I wasn't certain given

the body colour, and the fact that bands on a burned resistor are not always

their original colour.

I quick internet search brought up two

useful things; this resistor burning out is not uncommon, and the sender

is 30 ohms. However, I was sceptical of one forum's advice that the resistor

was 12 ohms.

At this point, a friend into old Holdens

came to the rescue because he had a working example of a similar gauge

from another model. It was indeed 82 ohms. I could imagine that it could

be interpreted as 12 ohms if it was read in the wrong direction, however.

It's 82 ohms, not 12 ohms as one forum suggests.

Dual Coil Meter.

If the gauge was just a simple ammeter,

it would work in laboratory conditions well enough. However, it must be

remembered that the car electrical system voltage fluctuates from around

12 to 14V. Thus, a simple ammeter would indicate a varying fuel level depending

on the engine revs and state of battery charge. Some cars have a voltage

regulator for the instruments to prevent this problem. In the Holden, there

is no such regulator - the gauge is simply fed with battery voltage of

whatever value that may be. So as to prevent voltage fluctuations affecting

the gauge, a special dual coil meter movement is used.

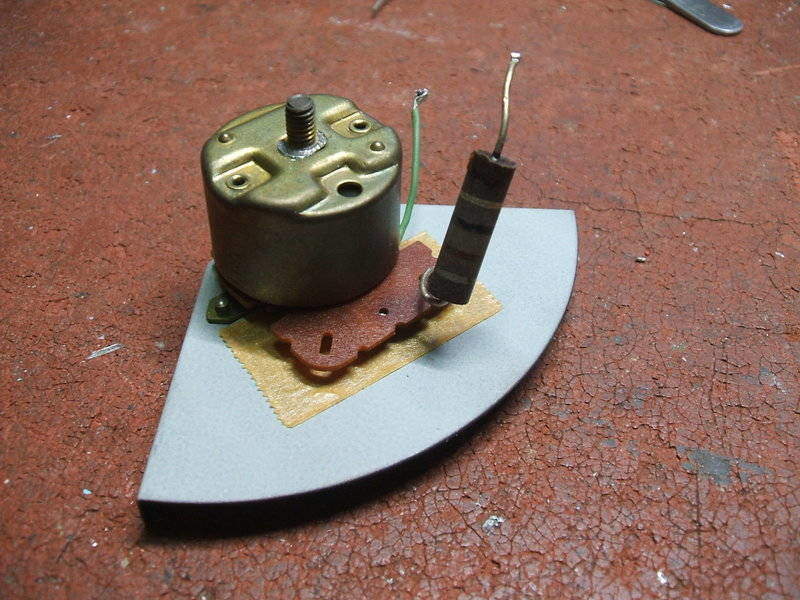

Simplified diagram of the fuel gauge circuit.

In essence, the meter's magnetic field

which drives the indicator needle is the combination of that from two coils.

The magnetic fields are such that they cancel each other out.

Looking at the above diagram, it can be

imagined that if the battery voltage rises, current through the left side

coil will increase, and so will its magnetic field, causing the needle

to deflect from its original position. However, the current in this coil

flows not only through the sender, but also to another coil. Therefore,

the magnetic field in this coil also increases, and because of its placement,

it starts to cancel out the field from the main coil. Thus, the needle

remains steady.

This is very simplified explanation, but

should help understand why it's made this way. Indeed, over an 11 to 14V

range, I found the reading did not fluctuate, once the gauge had been repaired.

In the above diagram, the resistor is

in series with the battery feed to the left side coil. Evidently, some

gauges made by another manufacture use a higher resistance coil instead

and don't include the resistor. The gauge I repaired with the resistor

is a VDO.

Repair of the Gauge.

The question now, was why did the resistor

burn out? Even though it was an IRC carbon resistor, low value examples

are usually very stable. If it was in the tens of k-ohms, it would have

been no surprise, but this was only 82 ohms.

Some further testing revealed we had a

design fault, and the resistor was being overloaded, but more of that later.

First thing was to confirm the resistor

value. The sender specifications were 30 ohms for a full tank, and 0 ohms

for an empty tank. This can be simulated with an ordinary rheostat - see

the first photo on this page. 82 ohms worked perfectly, with the gauge

showing an empty to full variation with the rheostat adjusted from 0 to

30 ohms. As a matter of curiosity, I tried 12 ohms. It too 'worked', but

the current was much higher, and could possibly damage the coil windings

over time - to say nothing of the fuel sender. At around half an

amp, the 12 ohm 1W resistor won't last very long either.

Because it was obvious that the 1W rating

was inadequate, I installed a 5W resistor. Short of the car's charging

system failing and the battery going open circuit, this new resistor can

never burn out again.

Unless the laws of physics change or the charging system fails,

this new 5W resistor cannot burn out.

The whole lot was then reinstalled in the gauge housing:

A Trap!

It is easy to assume that just the "bat"

and "sender" connections need to be used when testing the gauge. This is

not so, and one will think the gauge is still faulty after resistor replacement.

The

case of the gauge must be earthed! Unfortunately, there is no earth

wire running to the gauge as part of the instrument wiring, and unless

the gauge is screwed into the dash it won't work. When testing outside

the car, the negative must be connected to the case, as well as the substitute

sender.

Design Fault.

Some measurements made under varying operating

conditions show what the problem is.

| Sender Position | 12V Supply | 14.4V Supply |

| "Full" (30R) | 108mA (956mW) | 129mA (1.36W) |

| "Empty" (0R) | 127mA (1.32W) | 152mA (1.9W) |

The above table shows the resistor current

and power dissipation with 12V and 14.4V supplies, and with the petrol

tank full and empty.

One gets the impression that the designers

in the VDO laboratory only ever tested the resistor operating conditions

with a 12V power supply, and with an assumed full tank of petrol. In this

situation, the resistor is just within ratings. The worst case scenario

is with the battery charging and the tank near empty. Here, the dissipation

is almost double the rating!

From this, it could be assumed that those

owners who drove with a full tank all the time are less likely to have

their gauge fail.

It is true that resistors will survive

a degree of overload for some time, but as these cars are now over 50 years

old, we shouldn't be surprised at the failure. Replacement of the resistor

with a 5W type will always ensure it is always operating well within ratings.