Front view of converter shows 12V output socket, terminals, fuses and switching transistor.

Front view of converter shows 12V output socket, terminals, fuses

and switching transistor.

This project came about as the Model T

is equipped with a six volt electrical system and I'd bought a small air

compressor for tyre inflation that only worked on 12V. Having said that,

the more heavy duty model of the same compressor does in fact work quite

well on 6V. The higher the motor current of a 12V motor, the more likely

it will work satisfactorily on 6V.

Of course this unit can be used to power

other things; for example a Peltier effect car fridge, CB radio, mobile

phone etc.

Commercially made Converters.

6 to 12 volt converters have been a commonly

available commercially made product in the past. During the 1960's and

70's there were still many 6 volt cars in use, but most solid state car

radios and tape players were 12v only and so there existed a need for these

converters. Particularly common were VW Beetles up to 1966, and it's at

VW swap meets where such converters will often be found. Usually they sell

between $2 and $10. There's not a great demand for them these days, as

unfortunately many vintage cars have been converted to 12V. New ones can

still be purchased from some Model T parts, and other vintage suppliers,

but they're considerably more expensive. And of course, 2nd hand ones appear

on Ebay.

The design is much the same across the

different brands. In Australia, the Japanese "Bellsonic", once sold

by Dick Smith was particularly common. They use a two transistor oscillator

driving a step up transformer (often a ferrite toroid) with the same

transistors rectifying the stepped up voltage by means of their base emitter

junctions. The load current flowing through the base emitter junction gives

rise to a certain advantage. It is possible to arrange the converter to

automatically start when the load is turned on, thus obviating the need

for a switch on the converter. The Bellsonic unit is however, manually

switched, because there is a bleed resistor and pilot light permanently

across its output to assist with regulation. It is designed for under

dash installation where it's easily accessible.

Generally, the output is around 2A, although

I have one from a Porsche which provides about 6A.

As my compressor draws much more than

this, the commercially made units weren't really suitable for my needs,

hence the design you see here.

Designing a 6 to 12V converter.

Initially, I tried duplicating a typical

commercial unit by winding various transformers and experimenting with

differing methods of driving the transistors, but didn't really improve

on the commercial models. There was a 6 to 12V converter design published

in Electronics Australia during 1974 using an iron cored Ferguson transformer

which helped to understand the operation, but it was becoming clear that

to be able to draw say 8A at 12V would mean an input current of at least

16A at 6V. That's a lot of current and when one takes into account things

like transistor saturation voltage at that sort of current and the fact

we have only 6V to start with, a different approach was called for. One

important thing to consider was that the converter was only going to be

used for short durations with the high current loads; a few minutes to

pump up the tyres, or half an hour with the car fridge.

So why not use a small sealed lead acid

battery to supply the heavy current, but charge it at a lesser current,

which a simple converter can handle during its idle period? As it happened

I had a pair of 12V 4.2Ah SLA batteries looking for a use.

The idea worked out very well, and the

converter has been in operation since 2003.

The converter would have to be as small

as possible given lack of space in the Model T. The logical place for it

would be under the front seat. With not much space and the batteries in

the same enclosure, the design would had to be simple. While the idea of

one of my beloved vibrator power supplies and a home wound transformer

were tempting, the unit would be too bulky. And a vibrator supply on its

own had to be ruled out immediately; the switching contacts are only rated

at around 4A, meaning less than 2A for a 12V output, with efficiency taken

into account.

The Circuit and How it Works.

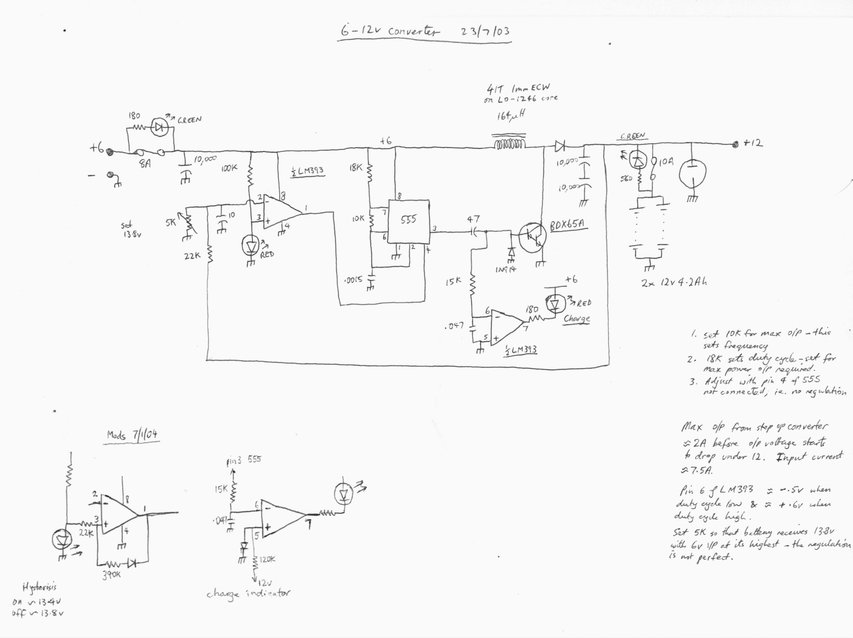

The circuit is essentially a simple switching converter to provide a voltage step up which provides 13.8V to charge a small battery. When the battery voltage reaches 13.8, the converter shuts off.

Step up circuit.

The incoming 6V supply is protected by

an 8A fuse. This is necessary in case the switching transistor shorts out,

which is the normal mode of failure with semiconductors. Filtering to reducing

incoming spikes, and ripple going back into the 6V supply, is performed

by a 10,000uF electrolytic condenser.

At the heart of the converter is the 555

oscillator. The frequency and duty cycle of the square wave output at pin

3 is set to provide the maximum current and voltage output from the converter.

These parameters are largely determined by the characteristics of the 164uH

choke. I used a ferrite toroid wound with 1mm copper wire for this.

When the BDX65A transistor is switched

on, current flows through the choke and builds up a magnetic field. When

the transistor turns off, the magnetic field collapses, creating a voltage

somewhat higher than the supply. It's standard solid state voltage converter

design. This higher voltage is rectified by a high speed power diode and

filtered by 5,000uF of capacitance.

Capacitive drive is used for the BDX65A.

As it's a Darlington type, not a huge amount of drive is required to ensure

saturation. Using capacitive coupling from the 555 means that if the oscillator

fails, the transistor cannot be permanently switched on. (Some commercially

made switchmode supply designers could take note of that).

When the output of the 555 goes high,

current flows through the 47uF and into the base. When the 555 output goes

low, the 47uF discharges through the 1N914 base diode and ensures the transistor

is cut off. This provides a clean switching waveform.

Unloaded, the output will rise to over

20V. The converter needs circuitry to prevent this as it would cause the

battery to be overcharged, damage loads connected to the converter, and

the converter would continuously run, always draining the car's 6V accumulator.

Regulation.

An LM393 comparator is used to sense when

the DC output reaches 13.8V. The output voltage is sampled and compared

with the voltage reference, which is a red led. Leds make good voltage

references because they are stable at around 2V and don't require much

current. If the voltage at pin 2 of the LM393 rises above 2V, pin 1 will

go low and shut off the 555. The converter then stops and will not restart

until the voltage has fallen again. This rapid turning on and off results

in an average voltage of 13.8 across the battery.

A later improvement as shown was to introduce

a degree of hysterisis with the comparator. This was because the converter

never really shuts off and was putting a small but constant drain on the

6V supply. A small amount of positive feedback was provided by the 390K

and 22K. The 13.8V now has to fall to 13.4V before the converter switches

on.

What happens now is there is a short burst

of about a second every few minutes where the battery is kept topped up.

Of course, as the 12V output is drained

the converter runs for a longer period, and with high loads runs continuously.

Charge Indicator.

To indicate the operation of the converter,

a red led is driven by the other half of the LM393. The negative input

is fed from the base of the BDX65A via a simple isolating resistor

and capacitor filter. When the transistor

is being driven, there exists a small negative voltage at the base due

to the 1N914. Thus the LM393 turns on, driving the led.

However, it was found that the led wasn't

always switching off when it should, and jacking up the positive input

by 600mV solved this. This meant there really had to be a definite negative

voltage at pin 6 to activate the charge led.

Inside the unit. The circuit was built on a piece of Veroboard.

The choke is mounted on the panel under the three electrolytic condensers.

Output.

In view of the battery load, the 5,000uF

filter capacitance might seem superfluous, but it serves two purposes.

First, to keep ripple down as the battery ages, and secondly for the setup

adjustment it's easier to run the converter without the battery to set

the voltage trimpot, so something is needed to filter the output.

On its own without the battery, continuous

output is around 2A at 12V. However, it shouldn't be used like this because

of the constantly changing voltage output. Unlike other switchmode supplies

which vary the duty cycle of the switching waveform, this one simply drives

at full output until the maximum required voltage is reached, then switches

off until it falls beyond a slightly lower point. This was done for simplicity.

While the duty cycle of a 555 can be varied by controlling the voltage

on pin 5, this also varies the frequency and reduces efficiency in the

choke circuit.

The battery is fused before it reaches

any other circuitry or the outside world. As with the input fuse, led indicators

show blown fuses. I thought this was a good idea as when out in the car

and something goes wrong it means one can narrow it down at a glance rather

than having to get out a test lamp or meter and start pulling things apart.

Construction.

I built up an aluminium box to fit under

the front seat. This also houses the two 12V 4.2A SLA batteries. On the

front are all the led indicators, fuses, and terminals. I provided a two

pin polarised socket of the type used in the house for the home lighting

plant, to which the 12V appliances can be plugged in. The unit is permanently

connected to the 6V accumulator in the car and runs even when the battery

isolation switch is off. There is another 10A fuse in an inline holder

to protect the always live supply to the converter.

As I've pointed out elsewhere, it is essential

not to let lead acid batteries discharge as they will be permanently ruined.

Apart from natural self discharge, there is a 500uA drain from the voltage

sensing circuit. While I always have the 6V accumulator connected to a

maintainer when at home, there is no problem with the converter discharging

it over several days away from home.

Operation.

This is completely automatic; one simply

uses the 12V load as required. However, due to the actual converter circuit

only being able to provide about 2A, one can see if more than this

is drawn, the SLA battery will discharge. With a 4A load one could, in

theory, run the converter for about four hours before its internal battery

is flat.

The other thing to keep in mind is the

charge rate from the car generator. I've set this to 5A, but at full output

the 6 to 12V converter pulls 7.5A from the car battery. With 12V loads

under about 2A, one can drive all day without anything discharging.

In practice, these limitations have not

caused any problems. The tyre compressor is only run for a few minutes,

and a trip to the shops and back with the 4A car fridge is less than an

hour.

Has anyone spotted the potential advantage

of incorporating the SLA battery? Well, it means that if the 6V car accumulator

was completely flat or faulty and one was away from home, then a jumper

wire can be run from the 12V terminal to the coil box and one could continue

driving. The CB radio or mobile phone is also not put out of action.

6 to 12V converter mounted under the front seat next to the radio.

While the converter worked well, it did require replacement of the SLA batteries after a few years. Given the cost of these, I eventually decided to replace the converter with a commercially made unit which can provide 6.3A at 12V. It appears to have been made in Germany and intended to be used in a Porsche. It can run the tyre compressor under load.