Inverter is compact, assembled in a zinc diecast box.

Inverter is compact, assembled in a zinc diecast box.

Transistor inverters can either be self

oscillating, or driven by a separate oscillator. In the self oscillating

type, the transformer itself provides the positive feedback required to

cause oscillation. However, loading and transformer design will affect

operation to a certain degree. Where frequency stability is important,

the inverter requires a separate oscillator to drive the switching transistors.

The oscillation frequency is thus independent of loading.

Over the years, I have built both types

of inverter. The self oscillating type is of course attractive because

of its extreme simplicity, and is perfectly adequate for many applications.

The inverter presented here was inspired

by a 1950's circuit from a Motorola transistor handbook. Although I have

built self oscillating solid state inverters before, I had not built one

with germanium transistors. With a large quantity of suitable transistors

available, it seemed like a good vintage solid state project.

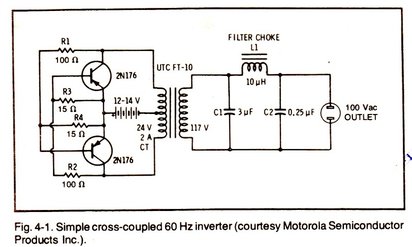

Circuit was based on this Motorola design from the late 1950's.

Circuit Operation.

The operation is that of a cross coupled

multivibrator. As can be seen from the circuit, the two transistors

function instead of vibrator contacts, and in that regard the inverter

works the same way; i.e., each half of the primary is alternately switched

across the 12V supply.

When power is applied, both transistors

will receive bias, and therefore be switched on, via the 100R resistors,

R1 and R2. However, because of slight component differences, one transistor

will turn on before the other.

Let's say the upper transistor turns on

first. The upper half of the transformer winding will now have current

flowing which induces an opposite current flow in the lower half. As the

upper transistor receives its bias from the lower winding via R2, this

is now reversed and the upper transistor switches off. The lower transistor

now switches on because R1 is now fed from the 12V supply via the upper

half of the winding. The 15R base resistors ensure the transistors are

turned off when they should be.

The frequency is dependent on the transformer

characteristics, but for the designs I have built around ordinary power

transformers, it has been around 50-60c/s.

It is harder to imagine a much more simple solid state inverter.

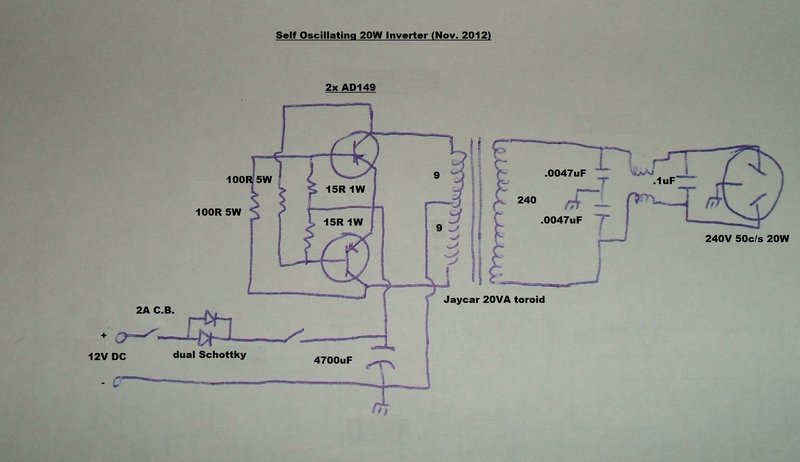

AD149 transistors.

I didn't have any 2N176's, but I do have

lots of AD149's. These are a T0-3 cased audio power transistor, designed

by Philips in the 1960's, and were very popular in Australia. They are

effectively the European version of the 2N301.

The AD149 has a maximum collector current

of 3A and a collector voltage of 30V. This was the first self oscillating

inverter I built with a toroid transformer and the results were excellent.

Not surprisingly, the performance was much better than similar inverters

using conventional laminated E-I transformers.

Inside of inverter shows a very simple construction. The dual Schottky

diode can be seen at the top between the transformer and switch. The 100R

resistors get hot, so need to be away from other components.

Construction.

All the circuitry is enclosed in a medium

size diecast box. With the circuit so simple, no PCB was needed. I used

transistor sockets for the AD149's because I had them, but also it just

makes wiring easier. The transformer is a Jaycar 20VA 240V to 18VCT type.

Overload protection is a 2A circuit breaker which will allow for a continuous

20W draw and allow for a few watts of inefficiency. Circuit breakers are

preferable to fuses because of the accidental overloads that occur. Provided

the inverter is designed properly, the breaker will trip before the transistors

fail.

Two AD149 germanium transistors do the switching.

Unlike a vibrator inverter, a transistor

inverter is polarity conscious, so a series diode is used for reverse polarity

protection. A 4700uF condenser bypasses the supply to provide a low impedance.

On the secondary side is a simple output filter out of a computer power

supply, and a neon indicator. The filtering arrangement used by the Motorola

circuit is wasteful so was not used. It was meant to create something resembling

a sine wave output. But, as most low current appliances are happy with

a square wave, I took the more efficient approach and applied only enough

filtering to remove RFI. For anyone constructing this inverter, the output

filter is optional and a .1uF capacitor will be sufficient for most applications.

During the design it was found that the

output voltage was too high. Unlike a vibrator inverter, this inverter

has a 100% duty cycle, so when a 9-0-9V primary is used with a 12V input,

the output will be higher than that of a vibrator inverter. Note that the

Motorola circuit has used a 12-0-12V transformer, and as a result the output

voltage is reduced to 100V instead of 117V.

As it happened, the voltage drop of the

reverse polarity protection diode was just enough to bring the output voltage

down to what it should be. The diode is a common dual Schottky type as

used in computer power supplies for rectification of the low voltage supply.

It is in a TO-220 package. These diodes are typically rated at 10, 20,

or 30A - all of which are suitable here.

The circuit can be used with silicon transistors,

but the 15R base resistors should be increased in view of the higher Vbe

(250mV for Ge, 600mV for Si).

One limitation of a cross coupled self

oscillating inverter like this, is that some power is wasted in the collector

base resistors. Of course, the greater the power output required, the more

base current that has to flow, and the hotter the resistor runs.

For this reason, high power self oscillating

inverters have a third centre tapped winding to drive the transistor bases

directly. Needless to say, that makes standard off the shelf transformers

unsuitable unless the extra winding is added.

Performance of this inverter is very good.

It appears to tolerate low power factor loads without upsetting the frequency

too much. In fact, I was able to run an 8W fluorescent lamp off it for

a short time, until the circuit breaker tripped (being LPF and allowing

for ballast losses, the real power consumption is somewhat higher).

I found with an 18W halogen lamp that

the inverter did not start with the lamp connected. It was necessary to

start the inverter first, then connect the lamp. Obviously, loading affects

the starting. Once the lamp had been operating, the inverter could then

be started with the lamp still connected. Apparently, the filament was

just too cold to start with, drawing more current that the inverter could

start with.

While 20W output might not seem like much,

many appliances can be used such as phone and USB chargers, portable CD

players, solid state radios, cassette recorders, etc.

Postscript: It's now August

2020 and this inverter has been in use for three years, operating a 10W

LED tube in a desk lamp, sometimes running for 12 hours at a time. The

desk lamp is a 20W fluorescent type with iron cored choke and glow tube

starter. The inverter (and LED tube) are not bothered by the choke being

left in circuit.